The quest for superior print consistency on demanding, high-speed label production lines is a constant challenge for printers. Achieving this level of quality, especially with intricate designs and a wide range of substrates, requires precise control over every aspect of the printing process. One of the most significant advancements in recent years that directly addresses this need is the integration of LED UV curing systems. These sophisticated systems offer a transformative approach to ink drying, fundamentally improving the predictability and repeatability of print quality on fast-moving web presses.

The Demands of High-Speed Label Printing

Label printing, particularly in the narrow web sector, operates at speeds that can test the limits of conventional printing technologies. Whether using flexography, offset, or other methods, maintaining sharp detail, vibrant color, and accurate registration at hundreds of meters per minute is a formidable task. Traditional curing methods, such as mercury UV lamps or hot air drying, often introduce variables that can compromise consistency. These variables include uneven energy distribution, heat-induced substrate distortion, and potential ink migration issues, all of which can manifest as print defects.

Understanding UV Curing in Printing

UV curing is a photochemical process where inks, coatings, and adhesives are instantly dried (cured) upon exposure to ultraviolet light. This process relies on specially formulated inks containing photoinitiators that absorb UV energy and initiate a rapid polymerization reaction, transforming the liquid ink into a solid film. The speed and efficiency of this transformation are critical for high-speed printing, as it allows for immediate handling of the printed web without smudging or contamination.

The Limitations of Traditional UV Systems

While mercury UV lamps have been the workhorse of UV curing for decades, they come with inherent drawbacks, especially in the context of high-speed label printing where consistency is paramount. These lamps generate significant heat, which can cause shrinkage or deformation of heat-sensitive label stocks, leading to registration problems and dimensional instability. Furthermore, mercury lamps emit a broad spectrum of UV light, but their energy output can fluctuate, and they require substantial warm-up and cool-down periods. This inconsistent energy delivery can result in incomplete curing, affecting ink adhesion, rub resistance, and overall print durability. The need for frequent bulb replacements and the disposal of hazardous mercury also add to operational complexities and costs.

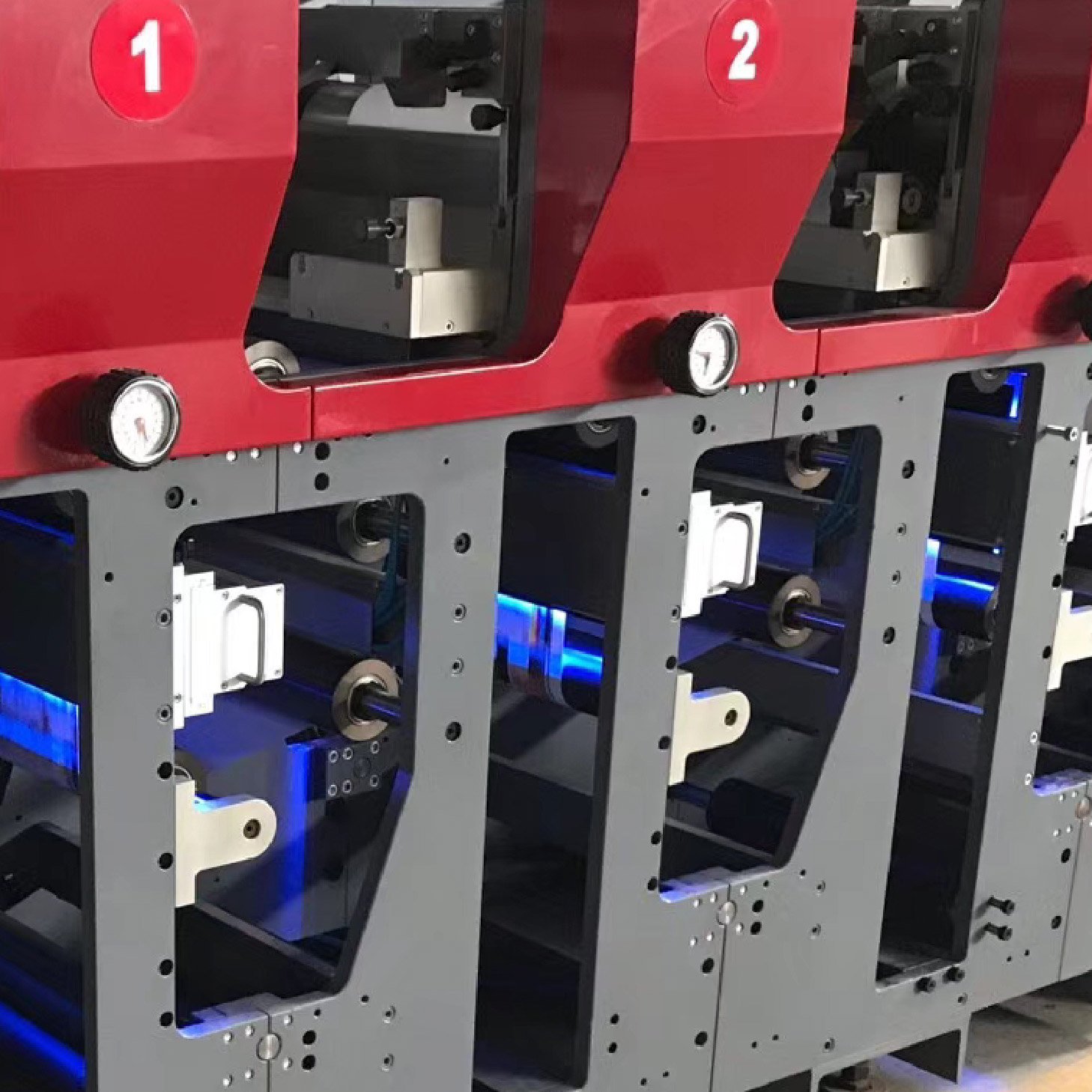

Enter LED UV Curing Technology

Light Emitting Diode (LED) UV curing represents a paradigm shift. Instead of a broad-spectrum lamp, LED systems utilize solid-state diodes that emit UV light at specific wavelengths. This targeted emission offers several key advantages that directly translate to improved print consistency on high-speed lines.

Precise Wavelength Control for Optimized Curing

LEDs can be engineered to emit UV light at precise wavelengths, typically in the UVA range (365 nm, 385 nm, 395 nm, 405 nm). This specificity is crucial because different inks and coatings are formulated to cure most efficiently at particular wavelengths. By matching the LED emission spectrum to the ink’s photoinitiator absorption spectrum, printers can achieve faster, more complete, and more uniform curing. This eliminates the inefficiencies of broad-spectrum lamps and ensures that the entire ink film cures evenly, regardless of line speed.

Minimal Heat Emission and Substrate Stability

One of the most significant benefits of LED UV curing is its remarkably low heat output compared to traditional mercury lamps. This is because LEDs are highly energy-efficient, converting a much larger percentage of electrical energy into UV light rather than heat. The reduced thermal load on the substrate is a game-changer for label printing. It minimizes the risk of heat-induced shrinkage or distortion, preserving the dimensional integrity of the label stock. This leads to significantly improved registration accuracy, especially on multi-color jobs and complex die-cut labels, where even minor shifts can render the print unacceptable.

Instant On/Off and Consistent Energy Output

Unlike mercury lamps that require warm-up and cool-down cycles, LED arrays can be switched on and off instantaneously. This “instant on/off” capability is invaluable on high-speed lines where production starts and stops frequently. It ensures that full UV output is available immediately upon demand, preventing under-curing during start-up. Moreover, LED output remains remarkably stable over their lifespan, with minimal degradation. This consistent energy delivery translates directly into repeatable curing results, batch after batch, ensuring that the print quality achieved at the beginning of a production run is maintained throughout.

Targeted Curing for Different Print Zones

Modern LED UV curing systems offer granular control over individual LED modules or zones. This allows printers to tailor the UV exposure precisely to specific areas of the web. For instance, if certain inks or coatings require different curing intensities or durations, the LED system can be programmed to deliver exactly that. This advanced control is particularly beneficial in hybrid printing applications, where different technologies or ink types might be present on the same label.

Enhanced Ink Adhesion and Durability

The efficient and uniform curing provided by LED UV systems leads to superior ink adhesion to a wide variety of substrates, including challenging plastics and foils commonly used in label applications. This enhanced adhesion results in improved rub resistance, scratch resistance, and overall durability of the printed label. For brands requiring high-performance labels that can withstand harsh environments or extensive handling, LED UV curing is an indispensable technology for ensuring longevity and maintaining visual appeal.

Reduced Energy Consumption and Environmental Benefits

Beyond print quality, LED UV systems offer substantial operational and environmental advantages. Their high energy efficiency translates into significantly lower power consumption compared to mercury lamps, leading to reduced electricity costs. The absence of mercury eliminates hazardous waste disposal issues, making LED curing a more environmentally friendly choice. The longer lifespan of LED arrays also reduces downtime associated with bulb replacement and associated maintenance.

Practical Considerations for Implementation

When considering the transition to LED UV curing systems for high-speed label lines, several factors are important. The selection of the appropriate LED wavelength and power output should align with the specific inks and substrates being used. Collaboration with ink manufacturers is key to ensuring optimal performance. Furthermore, the integration of LED systems into existing flexographic or offset presses requires careful planning to ensure proper placement and alignment for effective UV exposure across the entire web width.

Conclusion: A Clear Path to Consistent, High-Speed Label Printing

In the competitive landscape of label printing, achieving and maintaining exceptional print consistency on high-speed lines is not just a goal; it’s a necessity. LED UV curing systems provide a robust and reliable solution to this challenge. By offering precise wavelength control, minimal heat emission, instant operation, consistent energy output, and enhanced ink performance, LEDs empower printers to achieve unparalleled levels of repeatability and quality. The benefits extend beyond print consistency, encompassing reduced operational costs, improved substrate handling, and a more sustainable printing process. For label printers focused on efficiency, quality, and customer satisfaction, the adoption of LED UV curing technology represents a strategic investment in future-proof production capabilities.