Printing on synthetic materials presents unique challenges. Their non-porous nature and varying surface energies often lead to adhesion issues, slow drying times, and reduced print quality. Traditional curing methods struggle to keep pace with the demands of modern, high-speed printing presses, especially in the narrow web sector for labels and packaging. However, the advent and refinement of LED UV curing systems have revolutionized this landscape, offering unparalleled enhancements in print performance.

This technology addresses many of the inherent difficulties associated with synthetic substrates, paving the way for sharper graphics, increased durability, and more efficient production cycles. Understanding how LED UV curing systems achieve these benefits is key for any printer aiming to maximize their capabilities on these challenging materials.

Understanding Synthetic Materials in Printing

Synthetic substrates, such as polypropylene (PP), polyethylene (PE), and polyester (PET), are increasingly popular in the label and packaging industries. Their inherent strengths—resistance to moisture, chemicals, and tearing—make them ideal for demanding applications. However, their slick surfaces and low absorbency are precisely what make them difficult for conventional inks to adhere to.

Traditional solvent-based inks rely on evaporation to dry, a process that is inherently slow on non-porous surfaces. Water-based inks face similar challenges. Thermal curing, while an option, can sometimes degrade or warp thinner synthetic films due to excessive heat. This is where the rapid, energy-efficient nature of UV curing, particularly with LED technology, shines.

The Mechanics of UV Curing

UV curing involves inks, coatings, or adhesives that contain photoinitiators. When exposed to ultraviolet (UV) light, these photoinitiators absorb the UV energy and initiate a rapid chemical reaction. This reaction causes the liquid ink or coating to instantly polymerize, transforming from a liquid state to a solid, cured film.

Traditional UV curing systems typically use mercury vapor lamps. These lamps emit UV light across a broad spectrum. While effective, they come with drawbacks. They generate significant heat, require a warm-up period, and have a finite lifespan, needing frequent replacement. Their broad spectrum also means they emit heat and other wavelengths of light that are not strictly necessary for curing, leading to energy inefficiency and potential substrate damage.

The LED UV Advantage

LED UV curing systems utilize Light Emitting Diodes (LEDs) as their UV light source. Unlike mercury lamps, LEDs emit UV light at very specific wavelengths, typically in the UV-A range (around 365nm, 385nm, 395nm, or 405nm). This specificity is a game-changer for printing on synthetics.

Key Advantages of LED UV Curing:

- Targeted Wavelengths: LEDs are designed to emit UV light at wavelengths that perfectly match the absorption peaks of the photoinitiators in specialized UV inks and coatings formulated for synthetics. This ensures highly efficient energy transfer and complete curing.

- Instant On/Off: LEDs switch on and off instantaneously. This means no warm-up or cool-down time is needed, allowing for immediate start-up and shutdown of printing units. This is crucial for job changes and maximizing press uptime.

- Low Heat Emission: LEDs generate very little heat compared to mercury lamps. This is critical for printing on heat-sensitive synthetic materials like thin PE or PP films, preventing distortion, shrinkage, or delamination.

- Energy Efficiency: LEDs consume significantly less power than mercury lamps. They convert a much higher percentage of electrical energy into UV light, leading to substantial cost savings on electricity bills.

- Longer Lifespan: LEDs have an exceptionally long operational life, often exceeding 20,000 hours. This drastically reduces maintenance costs and downtime associated with lamp replacements.

- Environmental Benefits: The reduced energy consumption and absence of mercury in LEDs contribute to a more environmentally friendly printing process.

Enhanced Print Performance on Synthetic Materials

The unique characteristics of LED UV curing systems directly translate into superior print performance on synthetic substrates across various printing methods.

Narrow Web Flexographic Printing

In the narrow web flexo sector, where labels are produced for a vast array of products, synthetic materials are ubiquitous. From wine bottle labels to durable product identification tags, PP and PE films are preferred for their resilience.

- Superior Adhesion: LED UV inks, formulated with specific photoinitiators, cure rapidly and thoroughly on the non-porous surface of synthetics. This leads to excellent adhesion, preventing delamination or ink rub-off even in harsh environments. The targeted wavelengths ensure the ink fully polymerizes.

- Vibrant Color and Sharp Detail: The absence of heat buildup allows for finer anilox rolls and screens to be used, capturing intricate details and delivering sharp, high-definition graphics. Colors remain true and vibrant as the ink cures quickly without spreading or excessive trapping issues.

- High-Speed Production: The instant curing capability of LED UV allows flexo presses to run at their maximum speeds without compromising ink adhesion or finish quality. This boosts productivity and reduces lead times.

- Durability: LED UV cured inks exhibit exceptional resistance to abrasion, chemicals, and scuffing. This is vital for labels that will be exposed to handling, cleaning agents, or outdoor conditions.

Offset Printing (Sheetfed and Web)

While less common for narrow web, offset printing is used for broader applications on synthetic materials.

- Consistent Dot Gain: The precise control over curing provided by LED UV systems helps maintain consistent dot gain, crucial for achieving accurate color reproduction and smooth tonal transitions, especially with fine screens.

- Reduced Ink Set-off: Fast curing means inks are dry to the touch almost immediately, virtually eliminating ink set-off in the delivery pile. This is especially important when stacking printed sheets.

- Compatibility with Synthetic Papers: Specialized synthetic “papers” used in offset often have very smooth surfaces. LED UV ensures inks bond effectively without requiring heavy ink laydowns or extended drying times that could lead to smudging.

Specialty Coatings and Varnishes

Beyond inks, LED UV curable coatings and varnishes offer significant advantages on synthetics.

- Protective Overprint Varnishes: Applying a high-gloss or matte UV varnish cured by LED light provides a robust protective layer. This enhances scuff resistance and protects graphics from environmental factors, maintaining the premium look of the printed product.

- Tactile Effects: The ability to cure thicker layers of UV coatings with LEDs allows for the creation of tactile varnishes and special effects, adding a premium feel and visual interest to labels and packaging.

- Improved Slip Properties: Certain LED UV coatings can be formulated to enhance slip properties, making it easier for labels to run through automated filling or application machinery without sticking.

Optimizing for LED UV Curing on Synthetics

To fully leverage the benefits of LED UV curing on synthetic materials, several factors should be considered:

- Ink and Coating Formulation: It is imperative to use inks and coatings specifically designed for LED UV curing and the target synthetic substrate. These formulations contain the correct photoinitiators and resin systems to ensure optimal adhesion and cure.

- Substrate Preparation: While synthetics are generally clean, ensuring the substrate is free from oils, dust, or mold release agents is crucial for ink adhesion. Some primers can further enhance adhesion if necessary.

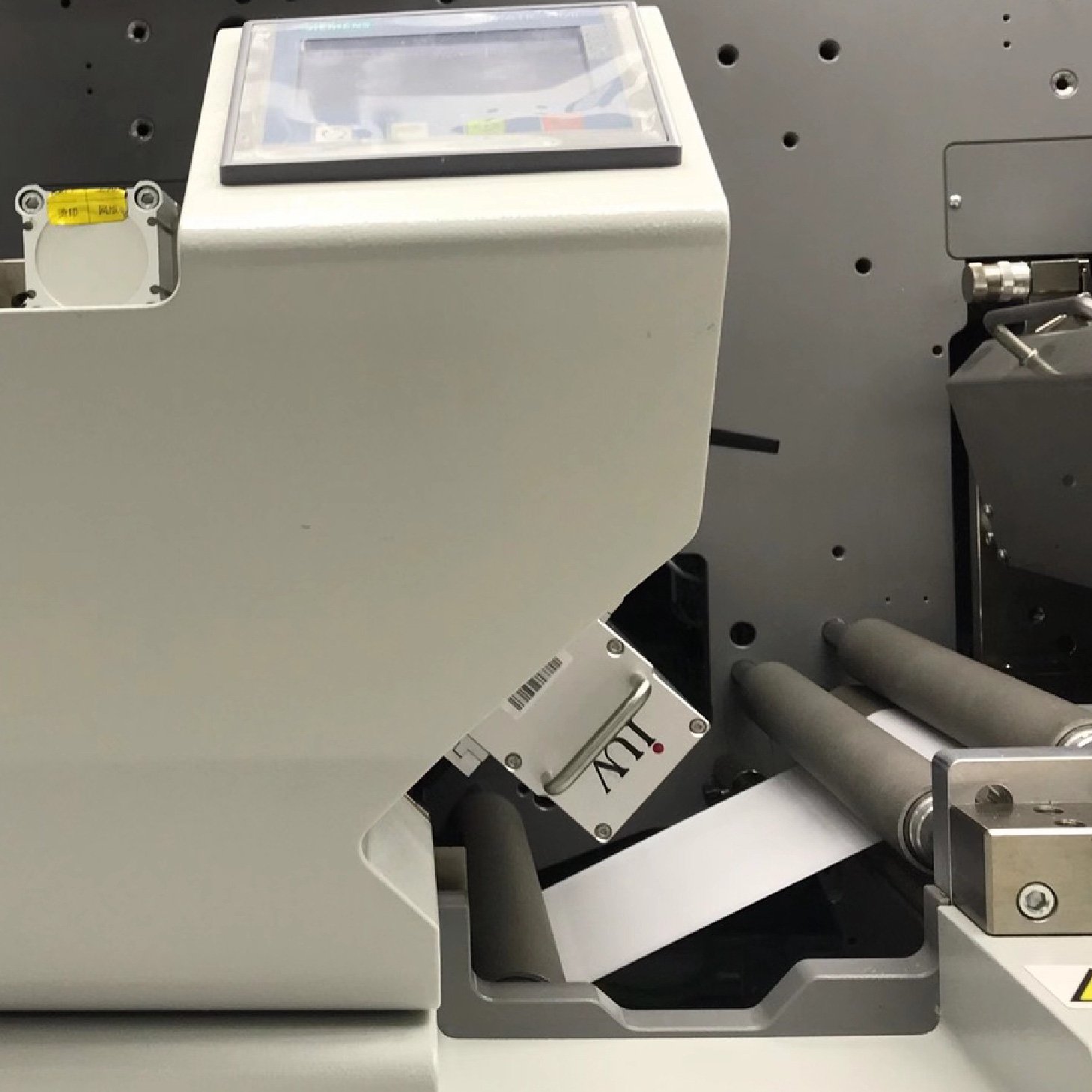

- Press Configuration: The placement and power of the LED UV curing units are critical. For narrow web flexo, typically a unit is placed after each printing station or at the end of the press. Proper alignment and distance from the substrate ensure maximum UV energy transfer.

- Wavelength Matching: Confirm that the LED UV lamps’ emission spectrum is correctly matched to the photoinitiator package within the inks and coatings. This is the cornerstone of efficient curing.

- Process Control: Monitor parameters such as press speed, ink laydown, and UV energy output. Consistent control ensures repeatable, high-quality results across all production runs.

The Future is Bright (and Cured)

The increasing demand for durable, high-performance labels and packaging on synthetic materials, coupled with the drive for greater production efficiency and environmental responsibility, makes LED UV curing systems an indispensable technology. For printers working with narrow web flexography, offset, and other applications involving PP, PE, and PET, embracing LED UV curing is not just an upgrade; it is a strategic move towards future-proofing operations.

By understanding the science behind LED UV technology and its direct impact on ink-substrate interaction, printers can unlock new levels of quality, speed, and cost-effectiveness. The ability to achieve robust adhesion, vibrant graphics, and exceptional durability on even the most challenging synthetic materials with minimal heat and energy consumption positions LED UV curing as the clear leader in modern printing solutions.