As the printing industry continues to evolve, staying ahead of technological trends is critical to maintaining efficiency and competitiveness. Among the innovations that have gained significant traction in recent years is LED UV curing technology. This cutting-edge technology has revolutionized the way printers approach curing and drying processes. It offers numerous advantages over traditional methods, particularly in the context of flexographic, letterpress, and narrow-web printing applications. By integrating LED UV curing into your operations, you can enhance both performance and sustainability while future-proofing your business.

Understanding LED UV Curing Technology

LED UV curing is a drying process that uses ultraviolet (UV) light emitted from LED lamps to cure or dry ink as soon as it’s applied to a substrate. Unlike traditional curing methods, which often rely on heat or mercury vapor lamps, LED UV curing uses much lower energy, is more precise, and produces a higher-quality finish.

The process involves the exposure of specially formulated inks to UV light. These inks contain photoinitiators that react to UV light, triggering a chemical reaction that hardens the ink almost instantly. This results in a print that is dry and ready for handling or further processing immediately after curing, without any risk of smudging.

Benefits of LED UV Curing in Printing

- Energy Efficiency

One of the most significant advantages of LED UV curing technology is its energy efficiency. Traditional curing methods, such as heat-based or mercury vapor curing, consume large amounts of energy, which can drive up production costs. LED UV curing, on the other hand, uses a fraction of the energy and has a longer lamp life. These energy savings make LED UV curing an attractive option for printers looking to reduce operating costs. - Faster Drying Times

LED UV curing provides near-instantaneous drying of inks. This means that prints are immediately dry and ready for the next step in the production process, whether that’s finishing, cutting, or packaging. This rapid drying time reduces bottlenecks in the production line and increases throughput, allowing for quicker turnaround times and higher productivity. - Improved Print Quality

LED UV curing enables higher-quality prints, with sharper images and better color vibrancy. The instant drying process prevents ink from smudging or bleeding, resulting in precise, crisp prints that retain their clarity even after handling. This is particularly important in industries where print quality is paramount, such as packaging, labels, and commercial printing. - Environmentally Friendly

Unlike traditional curing methods that emit harmful VOCs (volatile organic compounds) into the air, LED UV curing produces negligible emissions. Additionally, LED lamps do not contain mercury, which is present in some conventional UV lamps, making them a more eco-friendly choice. This reduced environmental impact is appealing to printers who are looking to meet sustainability goals and comply with increasingly stringent environmental regulations. - Reduced Heat Exposure

LED UV curing operates at lower temperatures compared to conventional curing methods. This is especially beneficial when printing on heat-sensitive substrates, such as films, foils, or paper with coatings that could be damaged by excessive heat. The lower heat output ensures that substrates maintain their integrity, reducing the risk of warping or distortion during the printing process.

LED UV Curing in Flexographic Printing

Flexographic printing, known for its ability to print on a wide range of substrates, is particularly suited to the integration of LED UV curing technology. Flexographic presses traditionally use solvent-based inks that require drying through evaporation. However, with LED UV curing, printers can use UV inks that dry almost instantaneously. This shift offers numerous benefits for flexographic printers:

- Faster Setup and Production Times: With LED UV curing, the need for long drying times is eliminated. This reduces the time required for press setup and speeds up the overall production process.

- Enhanced Substrate Compatibility: LED UV curing allows printers to handle a variety of substrates, including non-porous materials like plastic films, which were once difficult to print on using traditional methods.

- Reduced Environmental Impact: The transition to LED UV curing reduces the reliance on solvent-based inks and the associated emissions, aligning flexographic printing with greener practices.

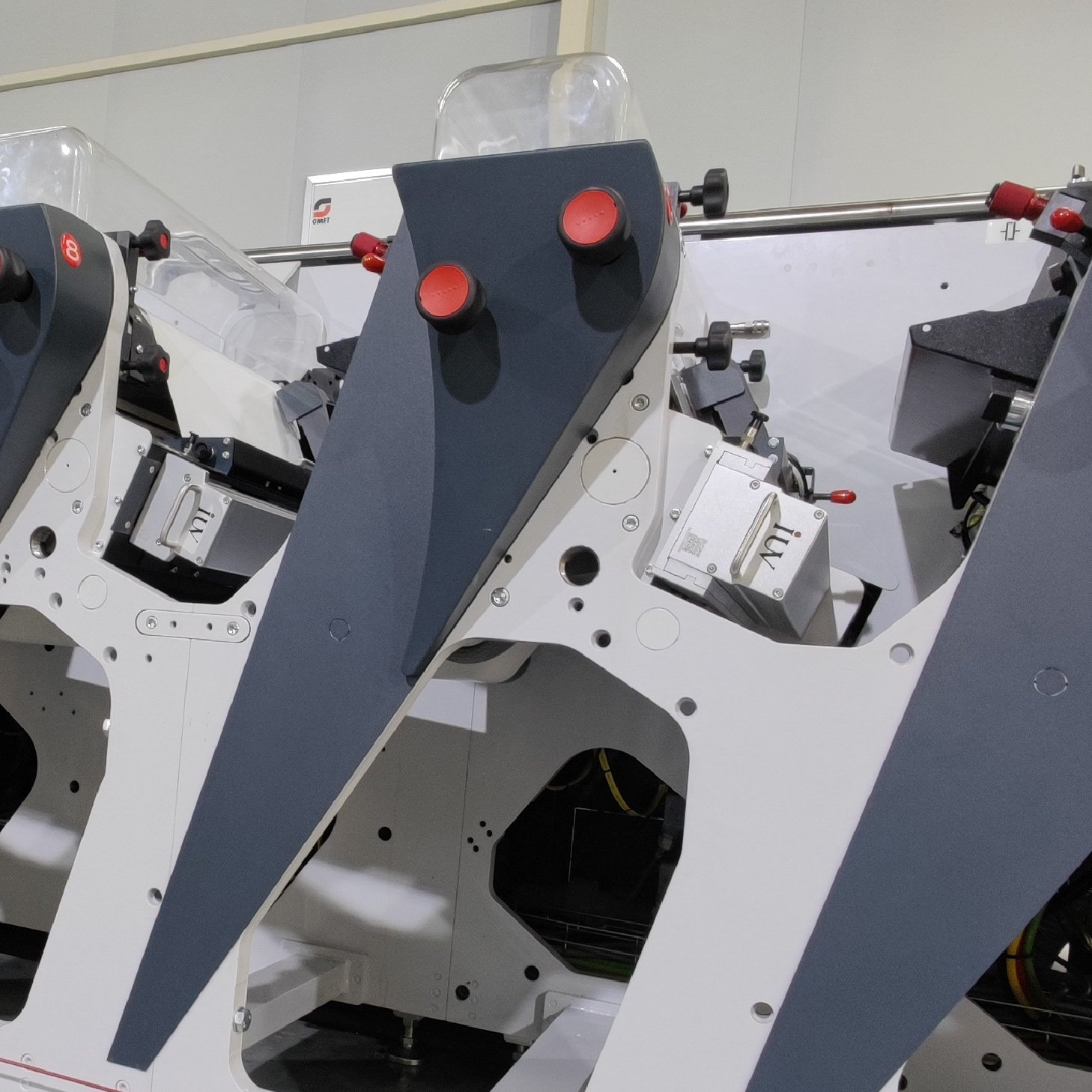

LED UV Curing in Letterpress and Narrow Web Printing

While letterpress printing has become less common in large-scale commercial production, it still finds a niche in high-quality, limited-run applications such as fine art prints, stationery, and specialty packaging. Narrow-web printing, on the other hand, remains crucial for label and packaging production. In both areas, LED UV curing technology offers substantial advantages:

- Precision and Detail: The precision of LED UV curing is particularly beneficial for letterpress and narrow-web printing, where fine details and sharp lines are essential. The fast curing process ensures that inks remain crisp and precise, enhancing print quality.

- Flexibility in Substrates: Narrow-web printers often deal with a variety of materials, including films, foils, and coated stocks. LED UV curing ensures that these materials are handled effectively, without any degradation or loss of print quality.

- Cost Reduction: The reduction in energy usage, as well as the lower need for cooling systems due to the reduced heat emitted by LED UV lamps, translates into significant cost savings for both letterpress and narrow-web printing operations.

LED UV Curing vs. Conventional UV Curing: A Comparison

While LED UV curing offers numerous advantages, it is important to understand how it compares to conventional UV curing, which relies on mercury vapor lamps. Here are a few key differences:

- Lamp Life

LED UV lamps have a longer lifespan compared to mercury vapor lamps. LED lamps can last up to 20,000 hours, while mercury vapor lamps typically last between 1,000 and 2,000 hours. This longevity reduces maintenance costs and downtime for lamp replacements. - Energy Consumption

LED UV curing consumes far less energy than traditional UV curing systems, which can result in significant savings over time, especially for high-volume printers. - Instant Curing

Traditional UV curing systems often require additional drying time or may not cure inks as efficiently on certain substrates. LED UV curing, on the other hand, provides a faster, more consistent cure across a variety of materials. - Environmental Considerations

As mentioned earlier, LED UV curing is a more environmentally friendly option. It produces fewer emissions, does not use mercury, and operates at lower temperatures. This makes it a preferable choice for printers looking to reduce their carbon footprint.

The Future of LED UV Curing in Printing

Looking ahead, LED UV curing technology is expected to continue playing a significant role in the printing industry. As ink formulations improve and the technology becomes even more affordable, more printers will adopt LED UV curing to enhance their production processes. The growing demand for sustainable practices and energy efficiency will further drive this transition.

For businesses aiming to stay ahead of the curve, investing in LED UV curing technology offers a clear path toward future-proofing operations. By embracing this innovation, printers can reduce costs, improve quality, increase speed, and align with sustainability goals. In the competitive landscape of modern printing, adopting LED UV curing may well be the key to achieving long-term success and maintaining a competitive edge.

Conclusion

LED UV curing technology represents a transformative advancement in the printing industry, offering significant benefits across a wide range of printing applications. By enabling faster drying times, superior print quality, energy savings, and environmental sustainability, it is clear why many businesses are making the switch to LED UV curing. Whether you’re involved in flexographic printing, letterpress, or narrow-web applications, incorporating this technology into your operations ensures you remain competitive, cost-efficient, and future-ready.