In the modern world of label printing, efficiency, quality, and versatility are paramount. Short-run label printing is a growing segment of the market, with businesses seeking cost-effective solutions to produce high-quality labels in smaller quantities. Traditional curing methods have their limitations, which is where LED UV curing systems come into play. These systems have revolutionized the short-run label printing process, offering distinct advantages over conventional curing techniques. This article explores the role of LED UV curing in short-run label printing, highlighting its benefits, challenges, and key considerations for manufacturers.

Understanding LED UV Curing Technology

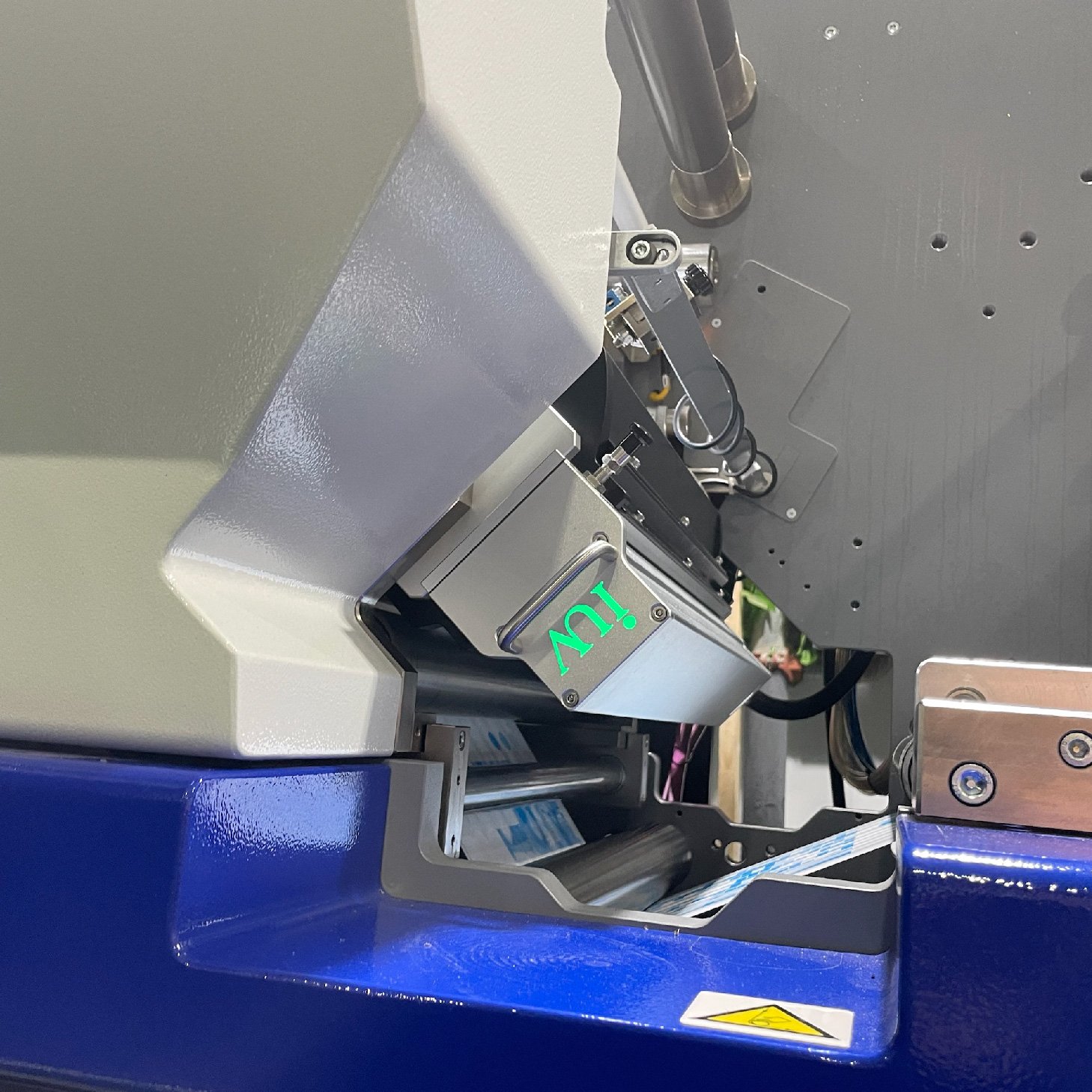

LED UV curing is a printing process that uses ultraviolet (UV) light to instantly dry or “cure” inks, coatings, and adhesives on printed materials. Unlike traditional mercury vapor lamps, which emit UV light over a wide spectrum, LED lamps provide a more targeted, energy-efficient light source. This allows for faster curing times, lower energy consumption, and greater durability in the final printed product.

In short-run label printing, LED UV curing systems are especially beneficial due to their ability to work effectively with various inks and substrates commonly used in label production, such as flexible films, paper, and synthetic materials.

Advantages of LED UV Curing Systems

1. Energy Efficiency

One of the standout features of LED UV curing systems is their energy efficiency. LED lamps consume significantly less energy than traditional mercury lamps. They generate less heat and require less cooling, which leads to a reduction in overall power consumption. This not only lowers operational costs but also makes LED UV systems a more environmentally friendly option for printers aiming to reduce their carbon footprint.

2. Faster Curing Times

LED UV curing systems offer fast curing times, allowing printers to increase their production speed. In short-run label printing, where turnaround times are often tight, fast curing is essential. LED UV lamps cure inks almost instantly, reducing drying times to mere seconds. This rapid curing minimizes bottlenecks in the printing process, allowing for more efficient use of time and resources.

3. High Print Quality

LED UV curing provides excellent ink adhesion, resulting in a high-quality finish. The instant curing process locks in the ink, preventing smudging and ensuring crisp, vibrant colors. In short-run label printing, where the quality of the finished product is crucial, LED UV curing helps to maintain consistency across all printed labels. It also enables the use of special effect inks, such as metallics, which are increasingly popular in label designs.

4. Wide Range of Substrates

LED UV curing is highly versatile, making it suitable for a wide range of substrates commonly used in label printing. Whether you’re working with paper, films, foils, or synthetic materials, LED UV curing ensures that the ink cures effectively without compromising the integrity of the substrate. This flexibility makes it an ideal solution for printers offering a variety of label types and sizes, including those in narrow-web printing applications.

5. Longer Lamp Life and Reduced Maintenance

Compared to traditional UV lamps, LED UV lamps have a much longer lifespan. LED lamps can last up to 25,000 hours or more, depending on the specific system. This reduces the frequency of lamp replacements and minimizes downtime associated with maintenance. Additionally, LED lamps do not require warm-up time, further enhancing productivity.

Considerations for LED UV Curing Systems

While LED UV curing systems offer numerous benefits, there are several considerations to keep in mind when integrating this technology into short-run label printing operations.

1. Initial Investment Costs

The initial investment required for LED UV curing systems can be higher compared to traditional UV curing equipment. The upfront cost of LED lamps and related components may be a significant factor for small or medium-sized printing businesses. However, the long-term savings in energy consumption and maintenance costs can offset this initial investment over time.

2. Ink Compatibility

LED UV curing requires specific types of inks that are formulated to cure under the specific wavelength of light emitted by the LED lamps. Not all UV inks are compatible with LED UV curing systems. Printers need to ensure that they are using the appropriate LED UV inks to achieve optimal curing results. Many manufacturers of LED UV printing systems now offer inks that are specifically designed for LED curing, but it’s essential to check compatibility before making the switch.

3. Curing Depth

While LED UV curing offers rapid surface curing, it can sometimes be less effective for deep curing, especially when printing on thick or heavily coated substrates. This issue can be mitigated by using the right combination of ink formulations and curing techniques, but printers need to be aware that certain materials may require additional layers or longer curing times to achieve the desired results.

4. Substrate Considerations

LED UV curing works best on substrates that are able to withstand the heat generated by the curing process. Some materials, especially thinner films or heat-sensitive substrates, may warp or distort under the heat generated by the LED lamps. Printers need to carefully consider the type of material they are working with to avoid substrate-related issues.

5. Print Speed vs. Quality

While LED UV curing allows for faster drying times, printers must balance speed with quality. In some cases, pushing the print speed too high may affect the quality of the final product. It’s crucial for operators to find the right balance between curing speed, ink density, and print quality to ensure that the labels meet the required standards.

Key Technologies in LED UV Curing Systems for Label Printing

1. Narrow-Web Printing Presses

Narrow-web presses are commonly used in short-run label printing, and LED UV curing technology is particularly well-suited for this type of printing. These presses are capable of handling a wide variety of substrates, and when paired with LED UV curing, they provide a powerful solution for producing high-quality labels at high speeds.

2. Flexographic Printing

Flexographic printing, or flexo printing, is one of the most popular methods for label production. LED UV curing has become an integral part of modern flexographic presses, providing faster drying times, improved print quality, and enhanced substrate compatibility. Flexo printers benefit from LED UV technology by producing labels with superior color vibrancy, sharpness, and durability.

3. Digital Printing

With the rise of digital label printing, LED UV curing is becoming an increasingly important component. Digital presses equipped with LED UV curing systems offer faster turnarounds, reduced waste, and enhanced print quality. LED UV curing is particularly useful for producing high-quality, short-run labels with custom designs, meeting the demands of brand owners who require flexibility and speed.

Conclusion

LED UV curing systems are transforming short-run label printing by offering faster curing times, improved print quality, and greater energy efficiency. While there are considerations, such as initial investment and ink compatibility, the advantages they bring to the industry are undeniable. Printers who adopt this technology can achieve high-quality results across a wide range of substrates while reducing operational costs and improving productivity. As the demand for short-run labels continues to grow, LED UV curing will play an increasingly central role in meeting the needs of the market.