For decades, mercury vapor lamps were the standard for UV curing in the printing world. They offered a powerful source of UV energy capable of drying inks and coatings quickly. However, these lamps came with several inherent drawbacks that are becoming increasingly problematic in today’s competitive and environmentally conscious market.

Mercury lamps operate at very high temperatures, generating significant heat. This intense heat can cause issues such as substrate distortion, especially with heat-sensitive materials common in label printing. It also requires substantial ventilation and cooling systems, increasing operational costs and energy consumption. Furthermore, the mercury within the lamps poses environmental and health hazards. Disposal of spent lamps is strictly regulated and costly, and there’s always a risk of accidental breakage and mercury release.

From a performance standpoint, mercury lamps emit a broad spectrum of UV light, including wavelengths that are not efficiently used for curing. This leads to wasted energy and can contribute to premature degradation of inks and coatings over time, impacting print durability and longevity. The lamps also have a finite lifespan and require regular replacement, adding to maintenance downtime and expense.

The Rise of LED UV Curing Technology

Light Emitting Diodes (LEDs) have revolutionized many industries, and printing is no exception. LED UV curing systems utilize solid-state semiconductor devices to emit UV light. Unlike mercury lamps, LEDs offer a highly focused and consistent output of UV energy. This precision in wavelength emission is a game-changer for printing processes.

The core advantage of LED UV is its ability to deliver specific UV wavelengths that directly activate the photoinitiators in UV-curable inks and coatings. This targeted energy transfer means that less energy is wasted, leading to more efficient curing. The typical wavelengths used in LED UV systems (e.g., 365 nm, 395 nm) are precisely matched to the absorption spectra of common photoinitiators, ensuring rapid and thorough curing.

Benefits for Narrow Web and Label Printing

The narrow web label printing sector has been an early adopter of LED UV technology, and for good reason. The unique demands of label production, which often involves printing on a wide range of substrates and running at high speeds, are perfectly met by LED UV.

Substrate Flexibility: The low heat output of LED UV lamps is a major advantage. It allows printers to run heat-sensitive materials like thin films, foils, and certain plastics without fear of warping or melting. This expands the range of applications and substrates that can be printed efficiently.

Energy Efficiency: LED UV systems consume significantly less energy than mercury lamps. They only draw power when the UV light is needed, and they don’t require a warm-up period. This translates to substantial cost savings on electricity bills, especially for operations running multiple shifts.

Faster Curing and Higher Speeds: The precise and intense UV output from LEDs enables faster curing times. This allows presses to run at higher speeds without compromising on ink and coating adhesion and finish. In a competitive market, increased throughput directly impacts profitability.

Improved Print Quality and Durability: The consistent and controlled UV output ensures complete curing of inks and coatings. This results in sharper images, better color vibrancy, and superior scratch and chemical resistance. For label printers, this means producing durable, high-quality labels that withstand demanding end-use environments.

Reduced Downtime and Maintenance: LED UV lamps have a significantly longer lifespan compared to mercury lamps, often lasting tens of thousands of hours. They also do not degrade over time in the way mercury lamps do, maintaining their curing performance consistently. This drastically reduces the frequency of lamp replacements and associated maintenance downtime.

Environmental Advantages: The absence of mercury eliminates the disposal concerns associated with traditional lamps. The lower energy consumption also contributes to a smaller carbon footprint, aligning with growing demands for sustainable printing practices.

Applications in Flexographic and Offset Printing

While narrow web printing has seen a rapid transition, flexographic and offset printing are also increasingly embracing LED UV technology.

In flexographic printing, particularly for packaging and corrugated board, LED UV offers similar benefits to label printing. The ability to cure quickly on a variety of substrates, including coated and uncoated papers, films, and boards, is crucial. The low heat is especially beneficial when printing on thinner packaging materials. Faster curing speeds also enable higher production rates, a key factor in the high-volume packaging sector.

For offset printing, especially in sheetfed and commercial applications, LED UV systems are proving to be a valuable addition. They allow for immediate handling of printed sheets, eliminating the need for anti-offset powders and reducing drying times. This is particularly advantageous for short-run jobs and applications that require fast turnaround times, such as direct mail or marketing collateral. The ability to print on non-absorbent substrates like plastics and foils opens up new creative possibilities for offset printers.

Considerations for Transitioning to LED UV

While the advantages of LED UV are compelling, a successful transition requires careful planning. Printers need to consider:

- Ink and Coating Compatibility: Not all existing UV-curable inks and coatings are formulated for LED UV wavelengths. Printers will likely need to switch to inks and coatings specifically designed for LED UV curing to achieve optimal results. This often involves consulting with ink manufacturers to select the right products.

- Wavelength Selection: LED UV systems are available with different peak wavelengths. The choice of wavelength will depend on the specific inks, coatings, and photoinitiators being used. A thorough understanding of the curing chemistry is necessary.

- UV Dose and Intensity: While LED UV offers precise control, printers must ensure that the system provides sufficient UV dose (energy per unit area) and intensity (power per unit area) for their specific applications. This involves understanding the requirements of different inks and substrates.

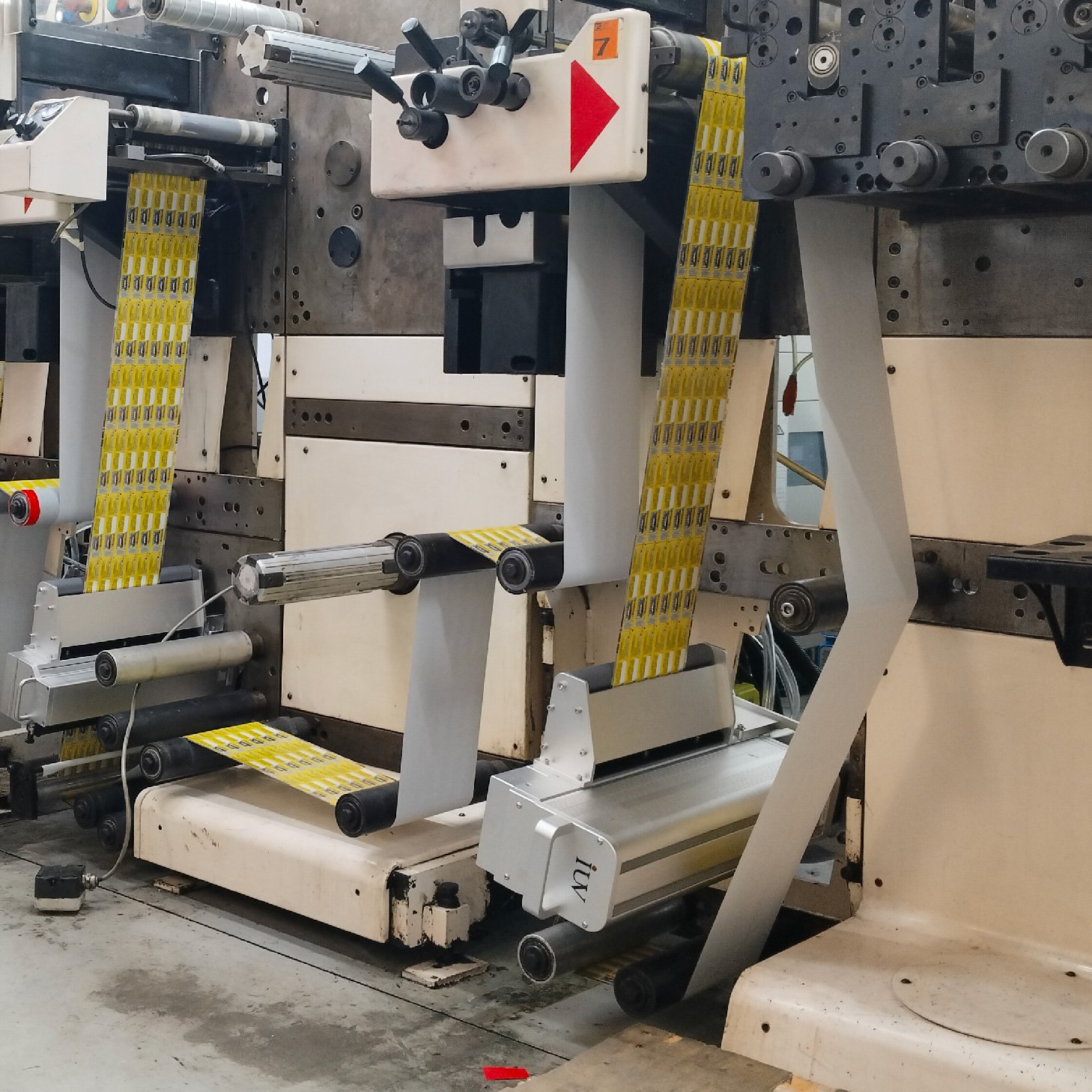

- Integration with Existing Equipment: Retrofitting existing printing presses with LED UV curing units requires careful consideration of space, power requirements, and ventilation. Some manufacturers offer integrated solutions, while others provide retrofit kits.

- ROI Calculation: While the long-term benefits of LED UV are clear, printers must conduct a thorough return on investment (ROI) analysis. This should include factors such as energy savings, reduced waste, increased throughput, lower maintenance costs, and the initial capital investment.

The Future is Cured with LED UV

The migration from mercury vapor to LED UV curing systems is a clear indicator of the printing industry’s commitment to innovation and efficiency. The technology offers a powerful combination of performance, cost savings, and environmental benefits that are increasingly critical for success. As the technology continues to mature and become more accessible, its adoption across all sectors of the printing industry, from narrow web labels to wide-format and beyond, is set to accelerate. Printers who embrace this transition are positioning themselves for a more profitable, sustainable, and competitive future.