Maximize Your Print Output: Modular LED Curing for Reduced Downtime

In the fast-paced world of printing, every minute of downtime translates directly to lost revenue and missed deadlines. For businesses in label printing, flexographic printing, offset printing, and narrow web printing, maintaining consistent, high-quality output is paramount. A significant bottleneck often lies in the curing process. Traditional UV curing systems can be rigid and difficult to adapt, leading to costly interruptions. This is where the power of modular LED curing systems shines, offering unparalleled flexibility and efficiency.

The Challenge of Downtime in Modern Printing

Printing operations face constant pressure to deliver more, faster, and with greater precision. Label printers, in particular, deal with short runs, frequent job changes, and a wide variety of substrates. Flexographic and offset printing, while often used for longer runs, still require efficient changeovers and minimal setup time to remain competitive. Narrow web printing demands high speeds and consistent ink adhesion.

When UV curing units fail or are not optimally configured for a specific job, the entire production line grinds to a halt. This can be due to lamp degradation, power supply issues, or an inability to match the curing needs of new inks and coatings. Replacing entire curing units is expensive and time-consuming. The downtime associated with troubleshooting and repair can cripple productivity.

Understanding LED UV Curing Technology

LED UV curing offers distinct advantages over traditional mercury vapor lamps. These lamps emit a narrow band of UV light, precisely matched to the absorption spectra of UV-curable inks, coatings, and adhesives. This focused energy transfer is highly efficient.

Key benefits of LED UV curing include:

- Instant On/Off: LEDs activate immediately, eliminating warm-up and cool-down times. This is a significant productivity boost.

- Longer Lifespan: LEDs have a lifespan of 20,000-30,000 hours or more, far exceeding mercury lamps. This drastically reduces replacement frequency.

- Lower Heat Emission: LEDs generate less heat, allowing for better print quality on heat-sensitive substrates and reducing the risk of substrate distortion.

- Energy Efficiency: They consume significantly less power than traditional UV lamps.

- Consistent Output: LED output remains stable throughout their life, ensuring consistent curing results job after job.

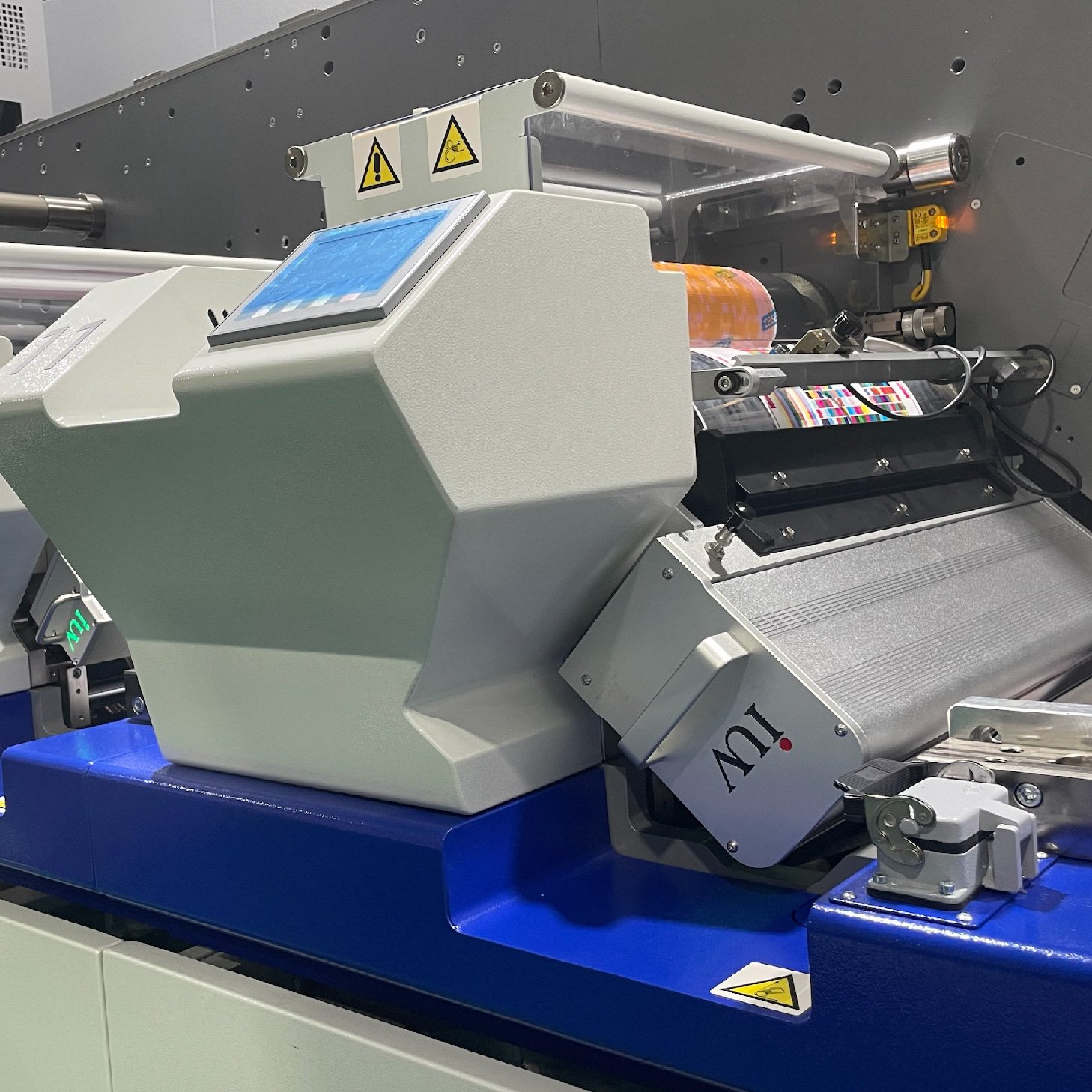

The Power of Modularity: Adapting to Your Needs

The true game-changer for reducing downtime is the modular design of modern LED UV curing systems. Instead of a single, monolithic unit, these systems are composed of individual, interchangeable modules. This configurability allows printers to precisely match their curing requirements to specific jobs and substrates, minimizing waste and maximizing efficiency.

Flexibility for Diverse Printing Processes

- Label Printing: Modular systems can be configured with varying numbers of LED modules and different wavelengths (e.g., 365nm, 395nm) to cure a wide array of inks, varnishes, and adhesives used on labels, from clear films to textured papers. If one module experiences an issue, it can be quickly swapped out without affecting the entire curing line.

- Flexographic Printing: For flexo applications, modular LED units can be placed at different stations on the press. This allows for in-line curing of multiple ink layers or coatings, or spot curing where needed. The ability to adjust the length of the curing zone by adding or removing modules ensures optimal performance for different press speeds and ink formulations.

- Offset Printing: In sheetfed or web offset, modular LED curing offers precise control over the curing of inks and coatings. If a particular section of the print needs more intense curing, additional modules can be inserted. If a job requires less curing energy, modules can be bypassed, saving energy and preventing over-curing.

- Narrow Web Printing: High-speed narrow web presses benefit immensely from the instant on/off nature of LEDs and the ability to precisely configure the curing zone. Modular systems can be tailored to the exact web width and the number of print stations, ensuring efficient curing without wasted energy or space.

How Modularity Directly Reduces Downtime

- Rapid Component Replacement: If a single LED module malfunctions, it can be isolated and replaced in minutes by an operator, often without needing a specialized technician. This dramatically cuts repair time compared to replacing an entire lamp assembly.

- Configurable for Any Job: Need more curing power for a new high-opacity ink? Simply add another module. Working with a delicate substrate that requires less heat? Remove modules or adjust their intensity. This prevents issues caused by an ill-suited fixed curing setup.

- Predictive Maintenance: Many modular systems offer diagnostics that can identify potential issues with individual modules before they lead to a complete failure. This allows for proactive replacement during scheduled maintenance.

- Scalability: As your business grows or your printing needs evolve, you can easily scale your LED curing capacity by adding more modules. This avoids the need for expensive, large-scale equipment upgrades and the downtime associated with installation.

- Optimized Energy Use: By configuring only the necessary modules for each job, you reduce energy consumption. This efficiency can indirectly contribute to system longevity and fewer unexpected issues.

Integrating Modular LED Curing into Your Workflow

Transitioning to a modular LED curing system is a strategic investment in productivity. When selecting a system, consider:

- Wavelength Options: Ensure the system offers the wavelengths required for your specific inks and coatings.

- Power and Intensity: Choose a system that can deliver the necessary UV irradiance for your fastest print speeds.

- Cooling: Effective cooling is crucial for LED longevity and consistent performance.

- Integration: How easily does the system integrate with your existing presses (label, flexo, offset, narrow web)?

- Service and Support: Look for manufacturers with a strong track record and readily available replacement modules.

By embracing the flexibility and efficiency of modular LED curing systems, printing businesses can significantly reduce costly downtime, improve print quality, and boost overall operational profitability. It’s about having the right curing solution, at the right time, for every job.