In the competitive label and packaging printing market, efficiency and cost-effectiveness are critical. Printers constantly seek ways to reduce production costs while maintaining high print quality. One of the most significant technological advancements in recent years is the adoption of LED UV curing systems. These systems offer tangible benefits in terms of speed, energy savings, and environmental impact. Understanding the return on investment (ROI) for LED curing systems is essential for printers looking to enhance operations across flexo, gravure, and narrow web presses.

Advantages of LED Curing in Label and Packaging Printing

LED UV curing systems provide instant polymerization of inks, coatings, and adhesives, eliminating the need for long drying times. This immediate curing not only accelerates production but also reduces space requirements in finishing areas. For label printers using narrow web presses, this is particularly advantageous, as press runs can be completed faster without compromising ink adhesion or print durability.

Unlike traditional mercury vapor UV lamps, LED systems consume significantly less energy. Energy consumption can drop by up to 80%, translating into measurable savings on electricity bills. Additionally, LED lamps produce less heat, allowing the use of heat-sensitive substrates like thin films, shrink sleeves, and pressure-sensitive labels without deformation. Reduced heat load also extends the life of press components and minimizes cooling requirements.

Flexographic Printing and LED Curing

Flexographic printing remains a dominant process for labels and packaging. The quality of print depends on precise ink transfer and consistent curing. LED UV curing systems offer uniform energy distribution across the web, ensuring consistent polymerization. This reduces ink wastage caused by under- or over-curing, particularly on high-speed narrow web flexo presses.

For printers transitioning from conventional UV to LED, the ROI can be realized quickly. Energy savings, reduced maintenance, and faster changeover times contribute to lower overall operational costs. In addition, LED curing supports modern water-based and UV-flexo hybrid inks, providing greater flexibility for specialty applications such as scratch-resistant coatings and metallic inks.

Gravure Printing Efficiency

Gravure printing, often used for high-volume packaging such as labels, flexible films, and cartons, benefits significantly from LED curing systems. The consistent intensity of LED lamps ensures rapid curing of high-viscosity inks without scorching or causing substrate wrinkles. This stability reduces waste during startup runs and press adjustments.

Moreover, LED systems enable immediate rewinding and finishing, which is crucial for high-volume production lines. Eliminating long drying tunnels allows packaging printers to save floor space and reduce the number of equipment units required. For corrugated and flexible packaging converters, these advantages translate directly into cost reductions and faster throughput.

Narrow Web Printing Considerations

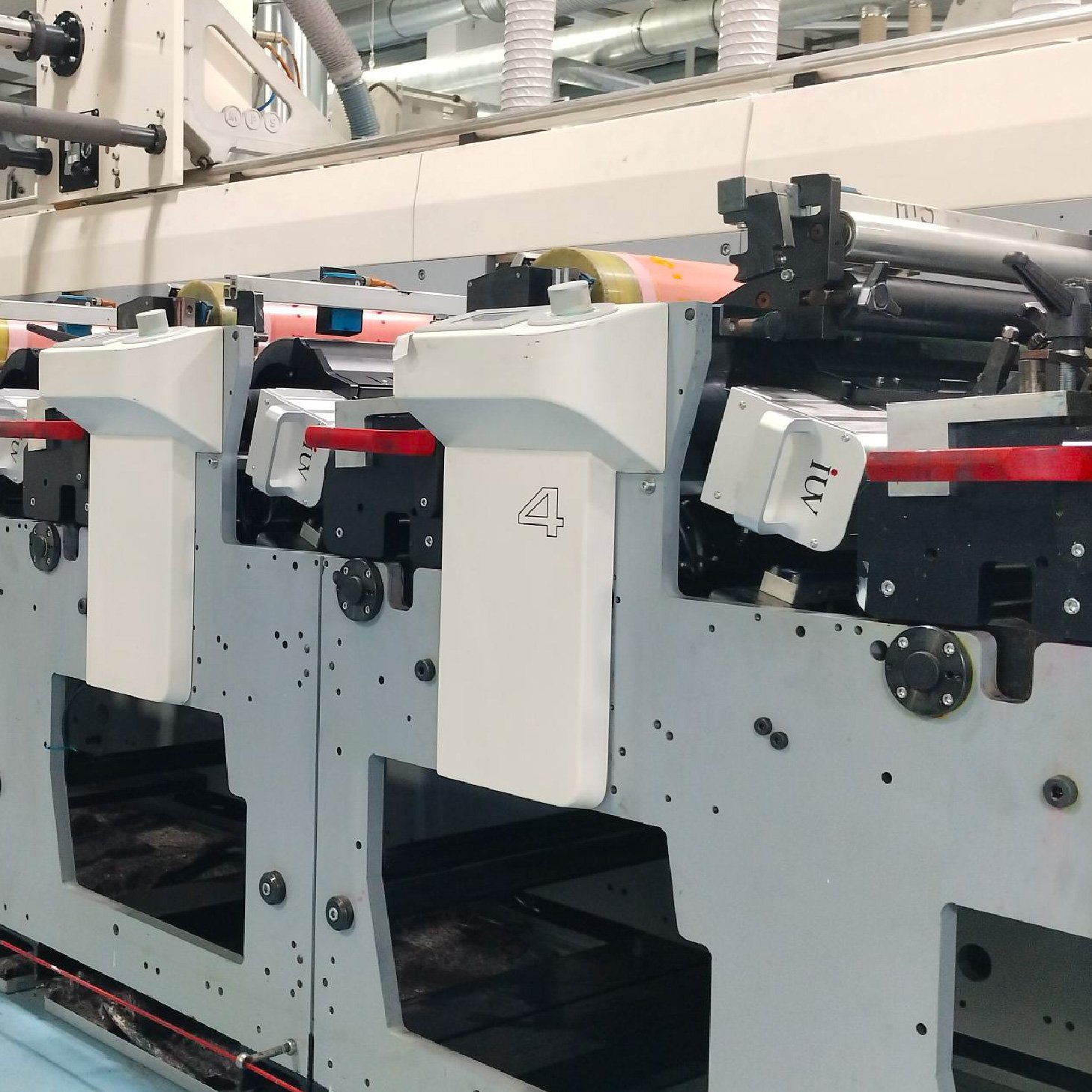

Narrow web presses often operate at high speeds with short run lengths. LED curing is particularly suited for these applications due to its compact size and instant-on capability. Printers can perform quick job changeovers without the warm-up times associated with traditional UV lamps.

The reduction in energy consumption and heat output also means less environmental control is required, minimizing additional infrastructure costs. For short runs, LED curing ensures consistent quality even at low press speeds, avoiding common issues like ink smearing or surface tackiness.

Calculating ROI for LED UV Systems

Determining ROI for LED curing requires analyzing several factors: energy savings, ink efficiency, maintenance reduction, production speed, and substrate compatibility. Energy savings are typically the most immediate benefit, with LED lamps consuming a fraction of the power of mercury lamps. Reduced lamp replacement and longer operational life further lower maintenance costs.

Ink efficiency improves because LED curing allows precise control of curing energy, reducing over-curing or under-curing. This precision is critical in high-value label applications where consistency is essential. Additionally, reduced heat output means fewer substrate rejects, lowering material costs.

The payback period varies depending on press type and production volume. For narrow web label printers, ROI can often be realized within 12 to 18 months. Larger flexo and gravure operations may see longer payback periods, but the cumulative savings in energy, labor, and materials make the investment worthwhile.

Environmental and Safety Benefits

LED curing systems provide significant environmental advantages. They contain no mercury and generate lower UV emissions, creating a safer workplace for press operators. Reduced energy consumption aligns with sustainability goals, making LED technology attractive to brands seeking eco-friendly suppliers.

Additionally, the cooler operation reduces HVAC requirements and extends the life of press components, further minimizing environmental impact. Waste reduction from fewer substrate rejects and lower ink consumption contributes to a smaller carbon footprint.

Implementation Strategies

Successful adoption of LED curing requires careful planning. Printers should evaluate substrate compatibility, press speed, and ink formulations before retrofitting or investing in new presses. Training press operators on LED-specific parameters ensures optimal curing and consistent output.

Integration with existing production workflows should prioritize quick changeovers, minimal downtime, and energy monitoring. Many printers achieve the best results by combining LED curing with modern workflow automation and inline quality control systems.

Conclusion

LED UV curing technology offers compelling benefits for label and packaging printers, from energy efficiency and faster production to improved print quality and sustainability. For flexo, gravure, and narrow web presses, the adoption of LED curing can deliver a rapid ROI while enhancing operational flexibility. Printers investing in LED systems gain not only cost savings but also a competitive advantage in speed, substrate versatility, and environmental responsibility.

By carefully analyzing energy, ink, labor, and maintenance costs, label and packaging converters can make informed decisions that maximize return on investment and ensure long-term profitability. LED curing is no longer just an option—it is a strategic tool for modern printing operations.