Embracing sustainable printing practices is more important than ever in today’s environmentally conscious world. Companies seeking eco-friendly certifications recognize that upgrading their equipment and refining their processes can make a significant difference. LED curing systems stand out as a pivotal innovation, especially in specialized printing sectors like label printing, flexography, plate printing, and narrow-web applications. This technology not only enhances production efficiency but also aligns perfectly with green certification standards, offering a greener footprint for modern printers.

The Rise of LED Curing in the Printing Industry

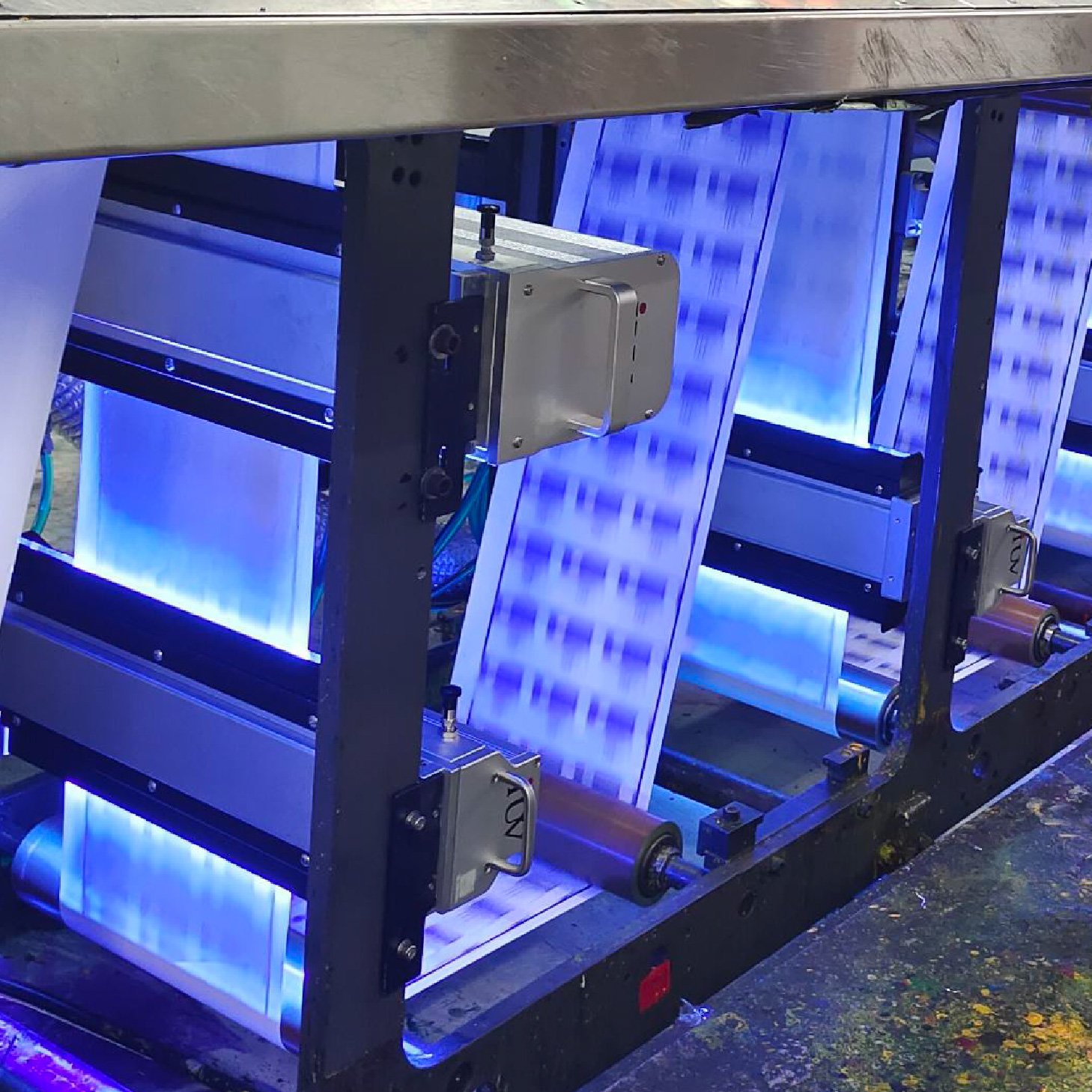

Traditional UV curing systems often rely on mercury vapor lamps. While effective, these lamps consume a considerable amount of energy and contain hazardous materials. In contrast, LED curing systems use light-emitting diodes—semiconductor devices that emit specific wavelengths of UV light. Their rapid start-up, low energy consumption, and long lifespan make them an appealing choice for environmentally focused manufacturers.

LED UV curing provides instant energy savings, reduces waste, and minimizes emissions. These systems significantly cut the carbon footprint of printing processes, helping businesses meet rigorous green standards such as FSC Certification, Green Seal, and ISO 14001. Technologies that foster sustainability without compromising quality are now vital to stay competitive and compliant.

Benefits of LED Curing Systems for Specialized Printing

Superior Energy Efficiency and Lower Power Consumption

Unlike conventional UV lamps, LED curing units turn on instantly and consume less electricity. They generate less heat, reducing the need for extensive cooling systems and energy-intensive waste management. For plant operations, this translates into reduced operational costs and a smaller environmental impact.

Extended Equipment Lifespan and Reduced Waste

LED modules last up to 10 times longer than traditional lamps, reducing the frequency of replacements and associated waste. This longevity supports a sustainable workflow, lowering manufacturing waste and minimizing hazardous material disposal. Fewer interruptions for maintenance lead to increased productivity.

Precise and Fast Curing Capabilities

LED systems offer pinpoint accuracy, curing selectively and rapidly. This trait benefits label printing, flexography, and narrow-web applications by boosting production speed and reducing energy use. The ability to instantaneously cure inks and coatings aids in achieving higher throughput with less environmental footprint.

Compatibility with Eco-Friendly Inks and Coatings

LED curing is ideal for use with environmentally preferable inks and coatings—such as low-VOC, water-based, or UV LED formulations—that are less harmful to health and the environment. This synergy promotes green certifications and aligns with corporate sustainability goals.

Impact on Different Printing Techniques

Label Printing

In label printing, precision and durability are crucial. LED UV curing ensures sharp, high-quality images, and enhances the adhesion of eco-friendly inks. The fast curing process accelerates production lines, enabling brands to quickly respond to market demands while reducing energy consumption.

Flexography

Flexo presses benefit from LED curing’s low heat output, enabling the use of heat-sensitive substrates, including recycled or biodegradable materials. This reduces waste and encourages sustainable packaging solutions, vital for meeting eco-label standards.

Plate Printing

In plate-based processes, LED curing provides stable and consistent curing performance, leading to cleaner edges and less ink spread. The compatibility with thinner and more delicate printing plates reduces material waste, aligning with environmental stewardship practices.

Narrow-Web Printing

Narrow-web printers often serve markets requiring high-quality, short-run jobs. LED UV systems facilitate quick color changes and fast turnaround times, all while consuming less power and generating less waste. These advantages contribute directly to greener throughput and better resource management.

How LED UV Systems Support Green Certification Goals

Implementing LED curing technology directly supports green certification objectives through various mechanisms:

- Energy Conservation: Essential to certifications that measure environmental impact.

- Reduced Hazardous Waste: Elimination of mercury lamps reduces disposal concerns.

- Lower VOC Emissions: Compatibility with recyclable and low-VOC materials reduces volatile organic compound emissions.

- Material Efficiency: Faster curing and less waste during press operation support sustainable practices.

- Enhanced Sustainability Reporting: Data from LED systems can bolster sustainability claims with measurable improvements.

Strategic Considerations for Transitioning to LED Curing

While the advantages are clear, transitioning to LED UV systems requires careful planning:

- Assessing Compatibility: Ensure existing presses and inks are compatible with LED curing.

- Investment Evaluation: Although initial costs might be higher, long-term savings and sustainability benefits offset upfront expenses.

- Training and Process Optimization: Staff should be trained to leverage LED systems fully, maximizing energy efficiency and throughput.

- Vendor Selection: Partner with experienced suppliers offering reliable, scalable LED curing solutions tailored to specific printing applications.

Future Perspectives in Eco-Friendly Printing

LED UV curing continues to evolve, introducing new wavelengths and more versatile formats. Enhanced lamp intensities and broader substrate compatibility expand its applicability. Over time, regulatory pressures and market demand will make LED curing an industry standard for sustainable printing.

This shift not only benefits environmental health but also fosters innovation and competitiveness. Assigning importance to greener technologies reflects a broader commitment to responsible manufacturing, aligning economic success with ecological stewardship.

If you’re considering enhancing your print shop’s sustainability, adopting LED curing systems offers a compelling path forward. By integrating this technology into your label, flexo, plate, or narrow-web printing processes, you’ll pave the way for greener certification, lower operational costs, and a stronger reputation for environmental responsibility.