In the ever-evolving world of printing, advancements in technology continue to shape the future of printing processes. One of the most significant innovations in recent years has been the development of modular LED curing systems. These systems have revolutionized the way printers approach curing processes, particularly in custom press configurations. Modular LED curing solutions offer flexibility, energy efficiency, and enhanced curing performance for various printing applications such as label printing, flexographic printing, letterpress printing, and narrow web printing. Understanding how these systems work and their impact on the printing industry is essential for staying competitive in today’s market.

The Role of LED UV Curing in Printing

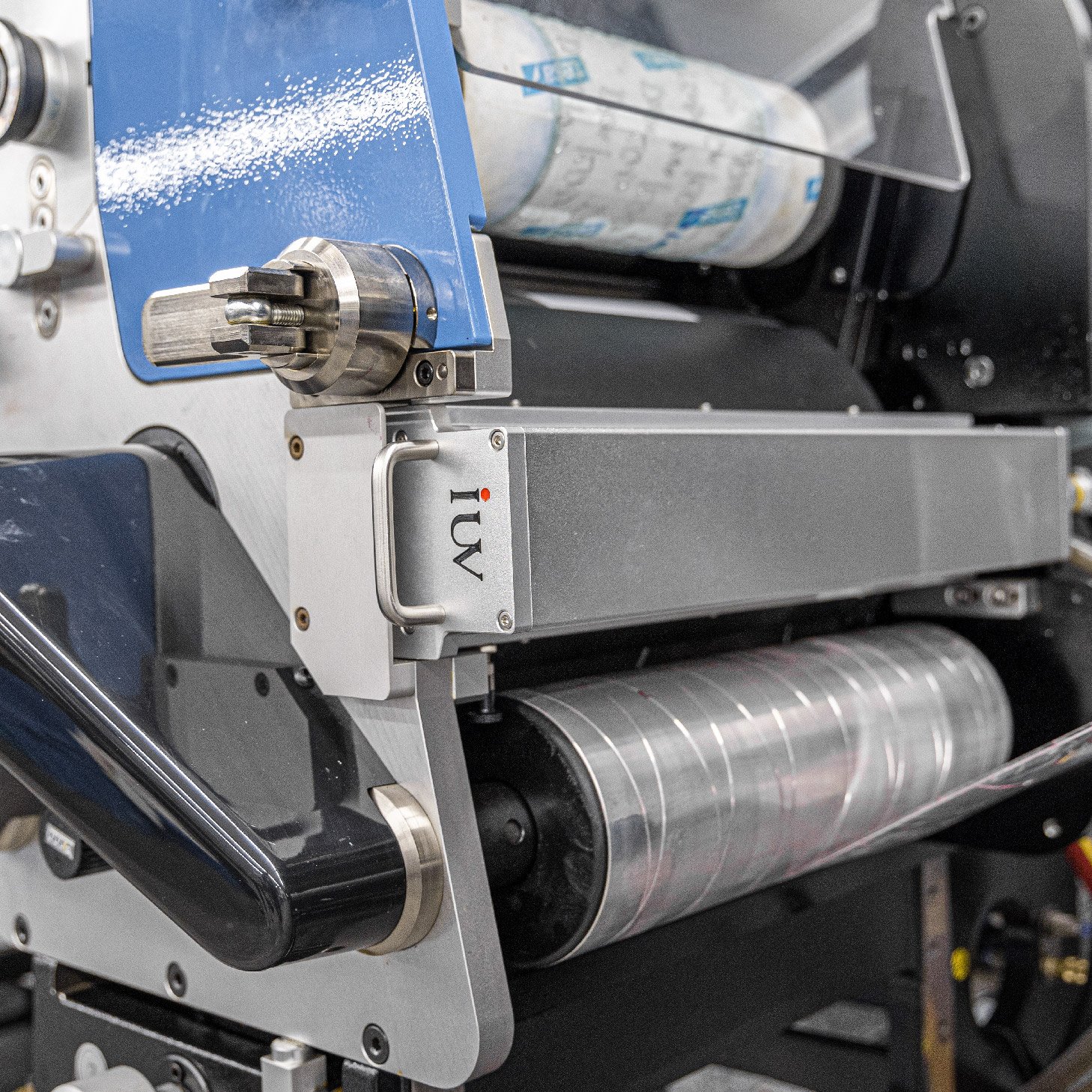

LED UV curing has emerged as one of the most promising technologies in the printing sector, especially for curing inks in various printing processes. Unlike traditional mercury vapor lamps, LED curing systems use light-emitting diodes (LEDs) that emit ultraviolet (UV) light at specific wavelengths. This UV light quickly cures the ink on paper, film, or other substrates, ensuring vibrant colors and sharp details in printed materials.

LED curing systems have several advantages over traditional UV curing methods. They offer faster curing times, lower energy consumption, and a longer operational life. Additionally, LED lamps generate less heat, which reduces the risk of substrate distortion, a common problem in high-speed printing applications.

Modular LED Curing Systems: Flexibility and Efficiency

One of the most significant advancements in LED curing technology is the development of modular systems. These systems consist of multiple LED units that can be arranged in a way that suits the specific needs of a printing press. The modular design allows for greater flexibility, as printers can adjust the configuration to optimize curing performance for different print jobs.

Modular LED curing systems are particularly valuable for custom press configurations, where print jobs vary in size, substrate type, and curing requirements. This flexibility is especially important in label printing, flexographic printing, and other narrow web printing applications, where printers need to accommodate different ink types and printing speeds.

Benefits of Modular LED Curing for Label Printing

Label printing is one of the most common applications for modular LED curing systems. The demand for high-quality, durable labels continues to grow, especially in industries such as food and beverage, cosmetics, and pharmaceuticals. Modular LED curing systems provide several key benefits for label printers:

- Precision Curing: LED curing systems offer precise and controlled curing, ensuring that inks are fully cured without overexposure. This leads to vibrant and consistent colors across large print runs, which is essential in label production.

- Speed and Efficiency: LED curing systems enable faster curing times compared to traditional methods, which improves overall productivity. This is particularly important in high-speed label printing, where maintaining print quality and speed are both critical.

- Energy Savings: LED lamps consume less energy than traditional UV lamps, reducing electricity costs for label printers. With energy efficiency being a top priority in modern manufacturing, LED curing systems offer a sustainable solution without compromising performance.

- Reduced Heat Generation: LED curing systems emit less heat compared to traditional UV curing methods. This reduces the risk of heat distortion, particularly in sensitive substrates such as films and thin labels, ensuring high-quality results.

Impact of Modular LED Curing on Flexographic Printing

Flexographic printing is another area where modular LED curing systems have made a significant impact. Flexography is widely used for packaging, including flexible packaging, corrugated boxes, and labels. The ability to cure inks quickly and efficiently is critical in flexographic printing, as it enables faster production times and higher throughput.

Modular LED curing systems offer several advantages for flexographic printers:

- Improved Ink Adhesion: The precision of LED UV curing ensures that inks adhere better to substrates, which is crucial in flexographic printing where ink transfer to uneven surfaces must be perfect for optimal print quality.

- Customization: Flexographic printing often requires different curing intensities depending on the substrate. Modular systems allow flexo printers to adjust the curing system to match the needs of each individual print job, ensuring the best possible results.

- Reduction in Waste: Faster curing times and more efficient ink curing lead to less waste. Since inks cure more precisely, the risk of overprinting or misalignment decreases, which leads to fewer rejects and waste during production.

Enhancing Narrow Web Printing with LED Curing

Narrow web printing, often used for packaging, labels, and tags, requires precise and high-quality results in a limited space. This makes LED curing a perfect match for narrow web applications. With modular LED curing systems, printers can fine-tune the curing process to achieve the best possible results for smaller print jobs, often with multiple color layers.

Modular LED curing systems allow printers to adjust the wavelength and intensity of the UV light, tailoring the curing process for specific ink types and substrates. The energy-efficient design of LED systems makes them especially suitable for narrow web presses that operate at high speeds.

Benefits Across Custom Press Configurations

Custom press configurations, where printers need to adapt to various substrates and job requirements, benefit significantly from modular LED curing systems. These systems offer the flexibility to scale and configure the curing process to meet the exact needs of each job, without requiring significant downtime for reconfiguration.

Some key advantages of modular LED curing systems in custom press configurations include:

- Adaptability: Modular systems can be customized to fit different press types, from small label presses to larger web presses. This ensures that printers can maintain high quality across a variety of print jobs.

- Consistency: LED curing ensures uniform results across multiple presses, reducing variation in print quality and ensuring consistency across different production runs.

- Cost-Effective: Modular systems allow printers to invest in just the units they need, reducing capital expenditures. Additionally, the long lifespan and energy efficiency of LED lamps lead to reduced operational costs over time.

Conclusion

The advancement of modular LED curing systems represents a significant leap forward in printing technology. These systems offer printers greater flexibility, enhanced curing performance, and improved efficiency across a variety of print processes, including label printing, flexographic printing, and narrow web printing. The modular design allows for customization, ensuring that printers can meet the demands of different substrates, ink types, and press configurations. As the printing industry continues to evolve, modular LED curing technology will play a critical role in enabling printers to meet the challenges of tomorrow while maintaining high-quality, cost-effective, and sustainable production.