Understanding LED Curing System Integration: Common Issues and Solutions

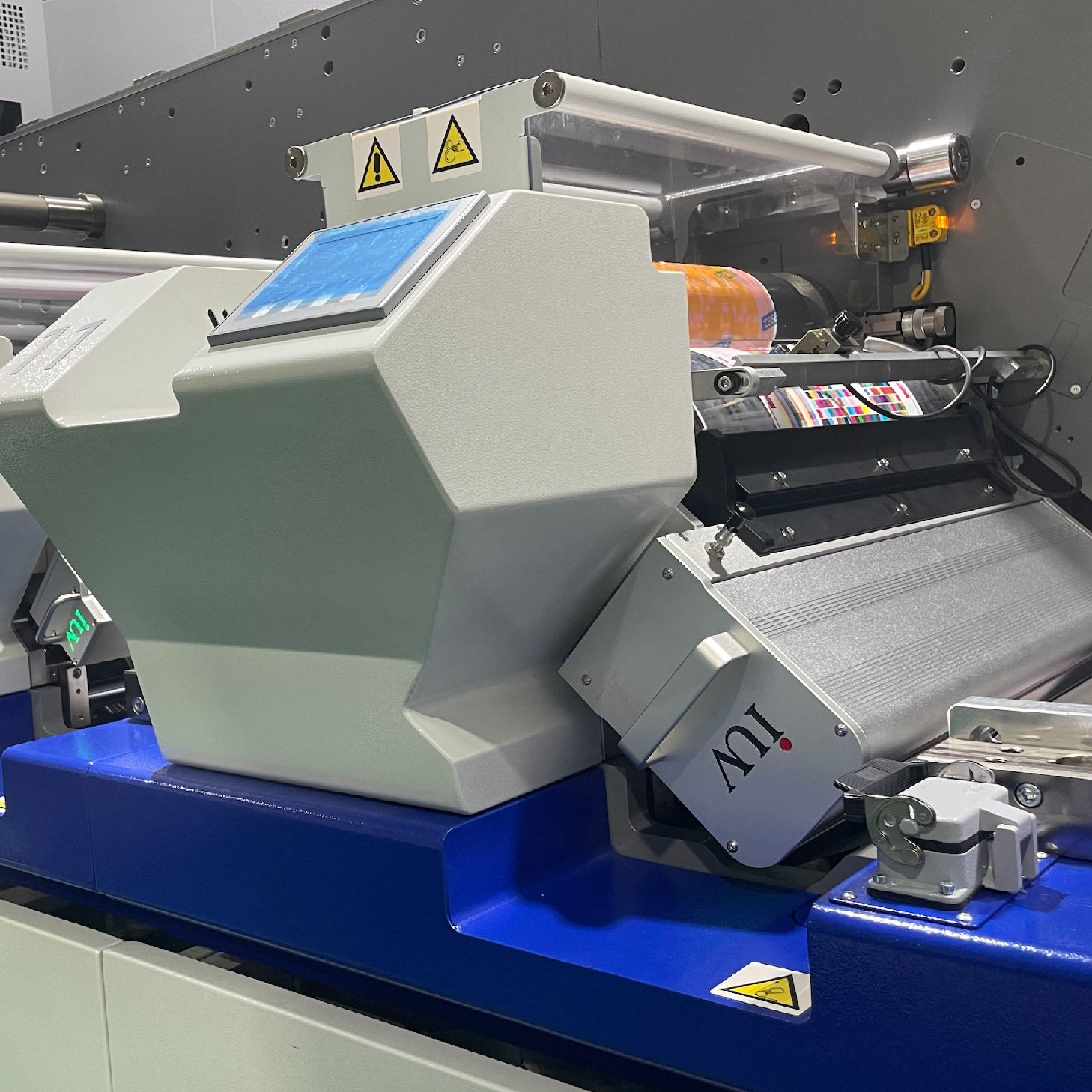

The integration of LED curing systems into various printing processes has revolutionized modern print production. Among these, label printing, flexographic (soft) printing, and rubber plate (plate) printing benefit significantly from LED UV technology due to its fast curing, low energy consumption, and environmentally friendly operation. However, technicians often face challenges when implementing LED curing modules, especially related to system stability, print quality, and process consistency.

This article explores common issues encountered during LED curing system integration and offers practical solutions to optimize print performance across multiple applications.

1. Inconsistent Curing and Ink Adhesion Problems

One of the most frequent hurdles is inconsistent curing, resulting in poor ink adhesion and variable drying times. This inconsistency can stem from uneven LED light distribution or insufficient UV exposure.

Cause Analysis:

- Insufficient LED wavelength match with the ink’s photoinitiators.

- Uneven mounting or alignment of LED modules.

- Incorrect curing dosage settings.

Solutions:

- Select LED light sources with emission spectra tailored to specific ink formulations, typically around 365-405 nm.

- Regularly calibrate and align LED modules to ensure uniform light distribution.

- Use irradiance meters to verify UV dose levels and adjust parameters accordingly.

- Implement inline sensors to monitor curing consistency in real-time, allowing immediate adjustments.

2. Heat Generation and Its Impact on Substrates and Ink

Although LED UV systems generate significantly less heat than traditional UV lamps, they still produce some thermal energy. Excess heat in narrow web presses or flexible packaging lines can lead to substrate deformation or ink breakdown.

Cause Analysis:

- High power LED modules without effective heat management.

- Poor ventilation or cooling systems.

Solutions:

- Incorporate proper heat sinks and cooling fans to dissipate thermal energy efficiently.

- Choose LED modules with built-in cooling mechanisms.

- Design the curing zone to enhance airflow around the LED modules.

- Monitor temperature levels continuously and set thresholds to prevent overheating.

3. Compatibility with Different Substrates and Printing Plates

Different materials and printing plates react differently under UV curing. The challenge lies in achieving rapid curing while avoiding substrate damage or plate distortion.

Cause Analysis:

- Mismatch between LED wavelength and substrate material absorption properties.

- Insufficient curing energy for thicker or non-porous substrates.

Solutions:

- Customize LED wavelength and intensity according to substrate specifications.

- Use specialized inks formulated for LED UV curing.

- Adjust curing parameters for different printing substrates, emphasizing higher energy for thicker materials.

- Conduct preliminary tests before full-scale production runs to validate curing effectiveness.

4. System Downtime and Maintenance Issues

LED modules can encounter failure due to dust, dirt, or aging components, leading to unexpected downtime and production delays.

Cause Analysis:

- Inadequate protective housings exposing LEDs to contaminants.

- Lack of scheduled maintenance.

Solutions:

- Install protective covers or enclosures for LED units.

- Establish routine cleaning schedules to prevent dust buildup.

- Replace aging LEDs proactively before failure occurs.

- Keep spare modules on hand to minimize downtime.

5. Troubleshooting Color Fidelity and Print Sharpness

LED curing impacts the final print quality, especially in color-rich applications such as label and flexographic printing. Poor color vibrancy and blurred edges are common issues.

Cause Analysis:

- Insufficient UV exposure compromising ink curing.

- Over-curing leading to ink brittleness or color shift.

- Inconsistent LED output intensity.

Solutions:

- Fine-tune curing parameters for optimal ink cure without overexposure.

- Choose high-quality LED modules with consistent output.

- Use color calibration tools and densitometers to monitor color accuracy.

- Experiment with curing speeds and energy doses during initial setup.

6. Achieving Precise Registration and Alignment

Accurate registration is paramount, especially in multi-color label printing involving narrow-web presses. Improper LED system setup can cause misalignment and ghosting.

Cause Analysis:

- Vibrations or mechanical misalignments affecting LED module position.

- Variability in curing across web movement.

Solutions:

- Securely mount LED curing units with fine adjustment controls.

- Synchronize curing operation tightly with press registration settings.

- Incorporate feedback systems to detect misalignments and correct on-the-fly.

- Conduct regular maintenance and calibration checks.

7. Selecting the Right LED Curing System for Your Application

Choosing the optimal LED curing system requires an understanding of specific operational needs and material compatibility.

Key Considerations:

- Type of printing process: label, flexo, or rubber plate.

- Substrate type and thickness.

- Ink formulation and required adhesion properties.

- Production speed and throughput.

- Long-term reliability and maintenance requirements.

Collaborate closely with LED suppliers and ink manufacturers to select tailored solutions that fit your workflow, ensuring maximum efficiency and print quality.

Final Thoughts

Integrating LED curing systems into traditional printing processes offers numerous advantages but also presents unique challenges. Properly addressing issues such as inconsistent curing, heat management, substrate compatibility, and maintenance can significantly improve print quality and operational stability.

Continuous testing, calibration, and system optimization are vital to harness the full potential of LED UV technology, transforming your printing operation into a more sustainable, efficient, and high-quality production environment. Whether in label printing, flexography, or rubber plate printing, understanding these common issues and their solutions keeps your press running smoothly and your output impeccable.