Upgrading Your UV Press with LED Curing Systems: A Complete Guide

The evolution of UV curing technology has significantly reshaped the printing industry, offering faster production times, improved print quality, and reduced environmental impact. For operators of existing UV presses, transitioning to LED curing systems provides a strategic edge in today’s competitive market. This guide explores the benefits, technical considerations, and practical steps involved in upgrading your press with LED curing technology, with a focus on applications like label printing, flexographic (flexo) printing, plate printing, and narrow-web operations.

Understanding LED UV Curing Technology

LED UV curing systems utilize light-emitting diodes to initiate the photopolymerization process of UV inks and coatings. Unlike traditional mercury vapor lamps, LEDs emit specific wavelengths, primarily in the UV-A spectrum, which activate photo-initiators in the ink. This results in rapid curing, less heat generation, and lower power consumption.

The advantages of LED UV curing include instant start-up, longer lamp life—often exceeding 20,000 hours—and minimized energy costs. Additionally, LEDs produce less ozone and UV noise, making the working environment safer and more compliant with environmental regulations.

Key Considerations for Upgrading Your UV Press

Before initiating an upgrade, assess your existing press specifications and operational needs thoroughly. Here are critical factors to consider:

- Compatibility: Not all presses are immediately compatible with LED UV systems. It may require modifications to the lamp housing, electrical systems, or cooling mechanisms. It’s advisable to consult with equipment manufacturers or specialists experienced in retrofitting presses.

- Power Supply and Control Integration: Ensure your press can accommodate the specific power and control requirements of high-intensity LED UV curing systems. Integration with existing controls can streamline operation and enable precise curing parameters.

- Inks and Coatings: Verify that your current UV inks and coatings are compatible with LED curing. While many PCB and specialty inks are suitable, some formulations may need adjustment, especially for high-opacity or thick coatings.

- Cooling Systems: Although LEDs generate less heat, maintaining optimal operating temperatures ensures consistent curing performance. Incorporate suitable cooling solutions if necessary.

- Cost-Benefit Analysis: While LED systems tend to be more expensive upfront, the long-term savings in energy, maintenance, and downtime often justify the investment.

Implementing the Upgrade: Step-by-Step Process

- Conduct a Detailed Assessment

Begin with a comprehensive review of your current press, including mechanical, electrical, and control systems. Identify areas requiring modifications for LED integration. - Select the Appropriate LED UV System

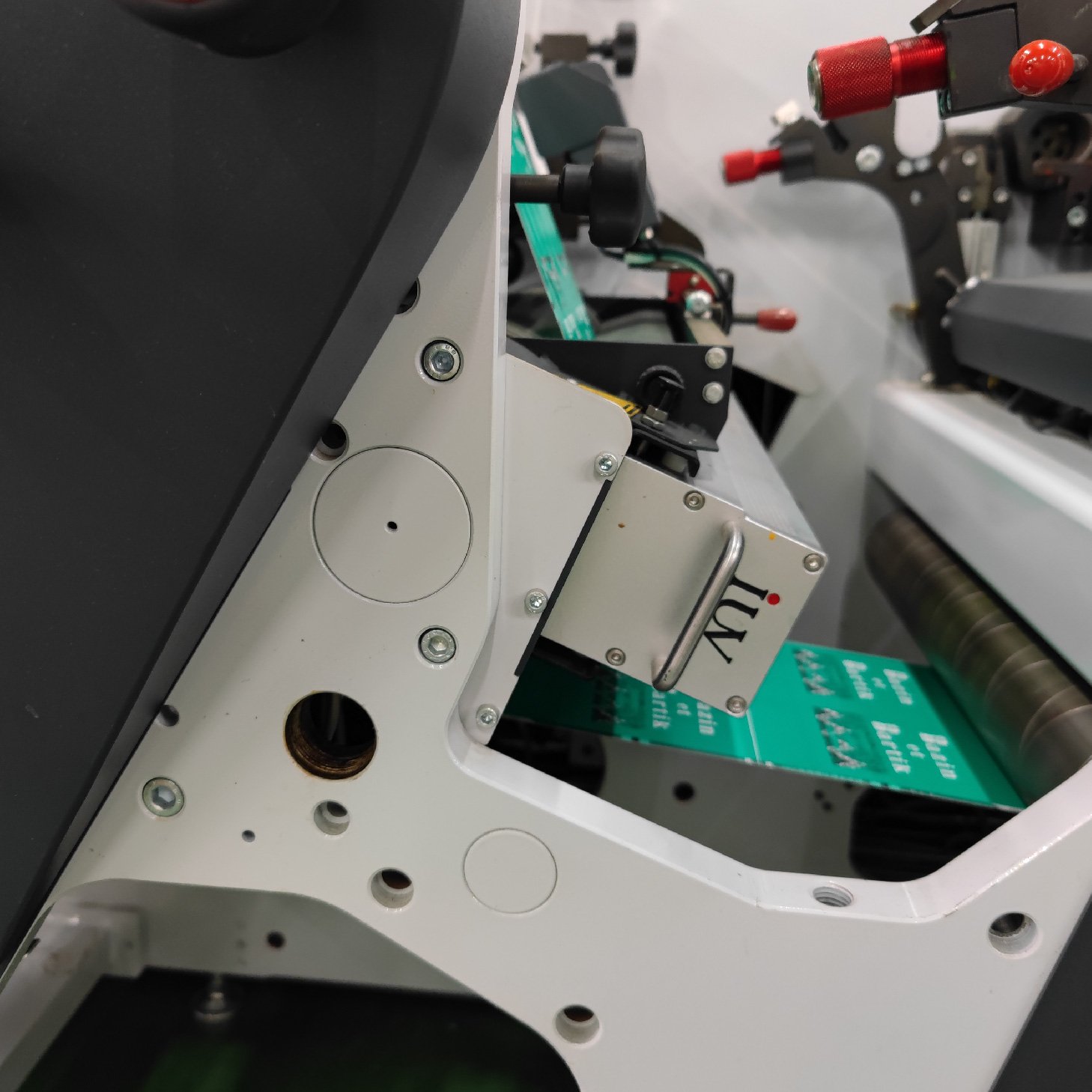

Choose a supplier that offers tailored solutions for your specific printing applications—labels, flexo, plates, or narrow-web. High-quality systems provide adjustable wavelengths, power levels, and integrated cooling. - Retrofit Mechanical Components

Modify lamp housings, reflectors, and cooling ducts if necessary. Ensure proper alignment of the LED modules to maximize curing consistency across the printed substrate. - Upgrade Electrical and Control Systems

Implement power supplies and control units compatible with your LED UV system. Set up programmable parameters for different jobs to optimize UV energy delivery. - Pilot Testing and Calibration

Before full-scale operation, conduct pilot runs to fine-tune curing settings. Monitor parameters such as ink adhesion, gloss, and curing speed to achieve desired quality standards. - Training and Maintenance

Train operators on adjusting LED-specific settings and performing routine maintenance. LED systems require different handling compared to traditional mercury vapor lamps.

Optimizing Your Printing Processes with LED UV Curing

Implementing LED curing can enhance various printing processes:

Label Printing

LED UV systems excel in label printing, especially for pressure-sensitive and flexible labels. Fast curing reduces production time, enables immediate winding, and decreases solvent emissions. Compatibility with various adhesive types and substrate surfaces makes LED UV ideal for complex label designs.

Flexographic Printing

In flexo presses, LED curing enhances productivity and color vibrancy. The reduced heat impact minimizes substrate distortion, enabling printing on heat-sensitive materials like thin films and foils. Adjusting the curing intensity ensures sharp imaging and consistent opacity.

Plate Printing

For plate printing applications, LED UV curing provides rapid ink setting and improved registration accuracy. The instant cure minimizes dot gain, ensuring high-fidelity reproduction of fine details and halftones. The ability to switch quickly between job runs boosts overall efficiency.

Narrow-Web Operations

In narrow-web presses, LED curing simplifies integration by enabling compact setups and reducing cooling requirements. High-speed curing capabilities support short-run, customized productions with excellent quality and minimal waste.

Addressing Common Challenges

While LED UV technology offers numerous benefits, some challenges may arise:

- Initial Investment: The upfront cost can be significant. However, long-term savings and increased throughput often outweigh initial expenses.

- Ink Compatibility: Ensure your inks are formulated or adaptable for LED curing. Partner with ink suppliers familiar with LED-compatible formulations.

- Technical Support: Work closely with experienced retrofit specialists to ensure seamless integration and troubleshoot issues during early operations.

Conclusion

Modernizing your UV press with LED curing systems opens doors to enhanced productivity, superior print quality, and a greener workflow. By carefully evaluating your equipment, selecting the right system, and following a structured retrofit process, you can unlock the full potential of LED UV technology. Whether you’re focusing on label production, flexo printing, plate work, or narrow-web applications, LED curing stands as a valuable upgrade in the evolving landscape of professional printing.