In the rapidly evolving world of label printing, staying ahead requires embracing innovative technologies that boost efficiency, quality, and sustainability. Among these advancements, LED curing systems stand out as a game-changer, transforming how printers approach UV curing processes across various printing methods including flexo, gravure, and narrow-width presses.

The Rise of LED Curing Technology in Label Printing

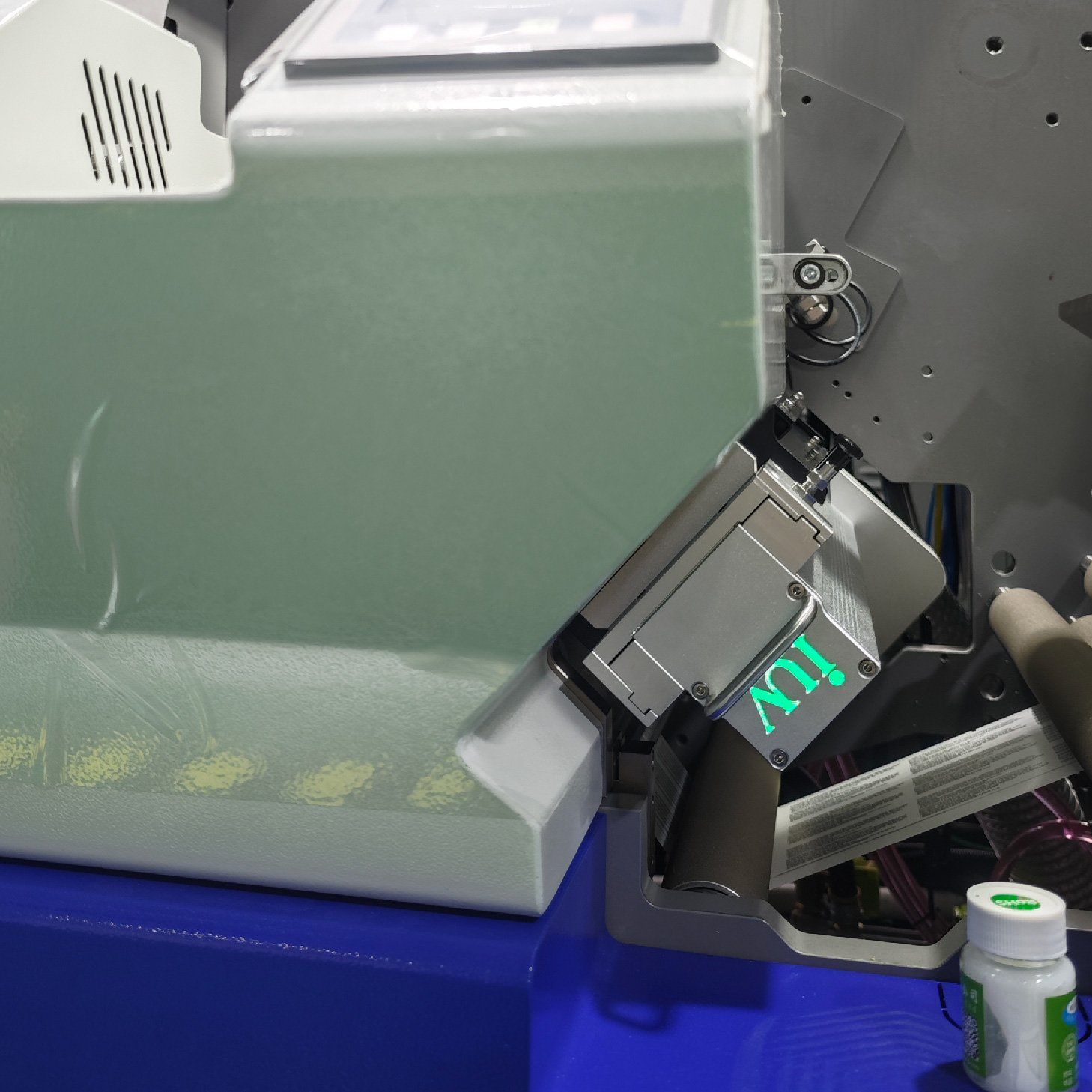

LED curing systems utilize light-emitting diodes that emit ultraviolet (UV) light to instantly cure inks, coatings, and adhesives. Unlike traditional mercury vapor lamps, LED UV systems offer numerous advantages, such as energy efficiency, longer lifespan, and lower heat generation. This technology precisely targets curing, reducing ink waste and enhancing productivity. As the demand for high-quality, fast-turnaround label production increases, LED UV curing becomes the preferred option for many printers.

Advantages of LED UV Curing in Flexo, Gravure, and Narrow-Width Printing

Flexo printing has often relied on conventional UV lamps to cure thin layer inks on various substrates. Integrating LED UV systems allows for faster curing times, which accelerates production lines and minimizes downtime. The instant curing also preserves intricate details and vibrant color quality, critical in label printing where visual impact matters.

Gravure printing, known for its high quality and fine detail, gains significant benefits from LED UV curing technology. The reduced heat during curing minimizes substrate distortion, preserving the structural integrity of delicate materials. This results in cleaner registration and sharper images. Additionally, the energy consumption drops considerably, making it more cost-effective over time.

Narrow-width presses, frequently used for specialty labels and short runs, particularly benefit from LED curing’s compact design and quick startup capabilities. The reduced warm-up time facilitates seamless switching between jobs, allowing smaller batches to be produced efficiently.

How LED UV Curing Enhances Label Production Efficiency

One of the key drivers behind the adoption of LED UV systems is the substantial increase in operational efficiency. LED curing offers instant turn-on, eliminating the warm-up delay common with traditional UV lamps. This minimizes machine downtime and maximizes uptime during shifts.

Moreover, the technology supports faster ink drying and curing speeds, which directly translates into higher throughput. As printing speeds increase, so does the ability to meet tight deadlines without compromising quality. This is especially advantageous when producing complex, multi-layered labels, or those requiring precise overprinting.

Environmental and Cost Benefits of LED Curing

LED UV systems align with the push toward greener manufacturing practices. They consume significantly less energy compared to traditional mercury lamps, reducing carbon footprint and operational costs. Additionally, UV LED lamps emit less heat, enabling the curing of heat-sensitive substrates such as holographic films or specialty label materials. This broadens the scope of label designs and finishes that can be produced.

LED curing also generates fewer hazardous waste by eliminating the need for lamp disposals containing mercury, making facilities safer and environmentally compliant. The longer lifespan of LED lamps reduces replacement costs and minimizes downtime caused by equipment maintenance.

Improving Ink and Coating Technologies with LED UV

The compatibility of LED UV systems with advanced inks and coatings unlocks new possibilities within label printing. Inks formulated specifically for LED curing offer faster polymerization rates and excellent adhesion qualities. This ensures vibrant colors, durability, and resistance to scratching or environmental factors.

Coatings designed for LED UV curing provide additional protection against moisture, UV degradation, and scuffing. When paired with LED curing, these coatings cure almost instantaneously, leading to a sleek, high-quality finish that stands out on retail shelves.

Practical Considerations for Implementing LED UV in Your Facility

Transitioning to LED UV curing requires evaluating existing equipment and production workflows. Compatibility with current press hardware is essential; many modern presses are designed or can be retrofitted for LED curing modules.

Investing in trained personnel ensures optimal system performance and maintenance. Regular monitoring of LED lamp output and proper calibration extend the lifespan of the technology and maintain consistent print quality.

Furthermore, selecting the right LED wavelength and power output tailored to specific inks, coatings, and substrates is critical. Working closely with suppliers and engineers can streamline the integration process, reducing downtime and initial investment risks.

Future Trends in LED Lighting for Label Printing

As LED technology continues to advance, future developments may include even higher energy efficiency, broader wavelength options, and smarter control systems. The integration of IoT and automation will enable remote diagnostics and real-time performance adjustments, enhancing productivity.

Innovation in inks, coatings, and substrates will further expand the capabilities of LED UV curing, allowing for more creative and sustainable label designs. The convergence of these technologies promises a future where label printing is faster, greener, and more versatile than ever before.

Conclusion

LED curing systems are actively shaping the future landscape of label printing across flexo, gravure, and narrow-width presses. Their ability to deliver rapid, high-quality curing while reducing environmental impact makes them an essential asset in modern workflow optimization. Adopting LED UV technology not only improves operational efficiency but also empowers printers to push creative boundaries, meet demanding schedules, and contribute to sustainable practices in the printing industry.