Adapting LED Curing Systems for Hybrid Printing Press Configurations

The world of printing technology is constantly evolving, and one of the most significant advancements in recent years is the adoption of LED UV curing systems. These systems offer impressive benefits in terms of energy efficiency, speed, and print quality. As hybrid printing press configurations gain popularity, the integration of LED curing systems is becoming increasingly important for improving production workflows, reducing costs, and enhancing the sustainability of printing operations.

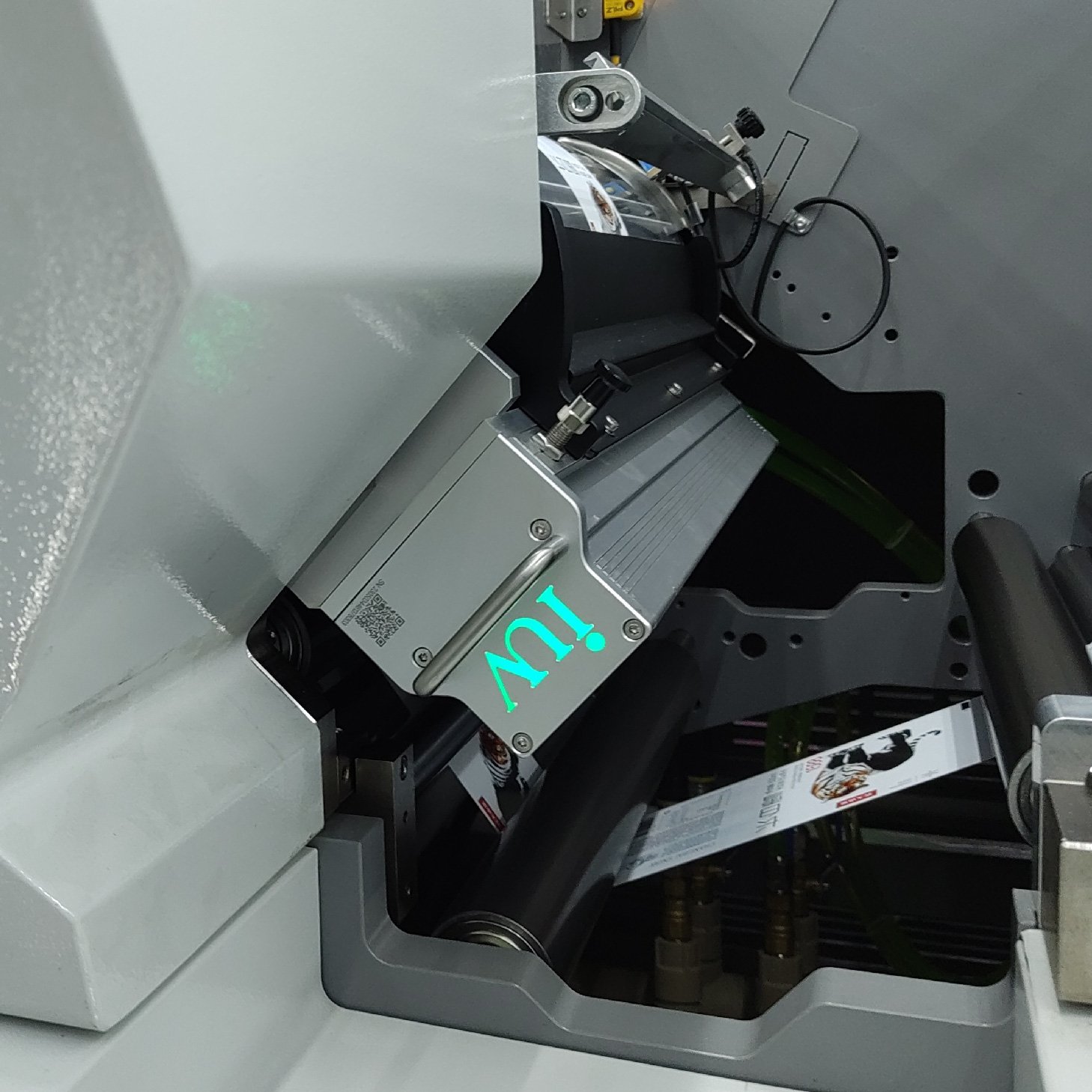

In this article, we will explore the key aspects of LED UV curing technology, its application in various types of printing, such as label printing, flexographic printing, and narrow-web printing, and how these systems can be adapted for hybrid press configurations to optimize performance.

Understanding LED UV Curing Technology

LED UV curing is a process that uses light-emitting diodes (LEDs) to cure or dry UV-sensitive inks and coatings. Unlike traditional UV lamps, LED lamps emit very little heat and consume far less energy. The ability of LED UV systems to cure inks instantly leads to faster production speeds, more durable prints, and the ability to print on a wider range of substrates.

The key advantage of LED UV curing lies in its energy efficiency. LED lamps use up to 50% less energy than conventional UV lamps and have a longer lifespan, resulting in lower operating costs. Additionally, the technology produces less ozone and heat, making it a more environmentally friendly choice for printers looking to reduce their carbon footprint.

The Rise of Hybrid Printing Presses

Hybrid printing presses combine different printing technologies, allowing printers to leverage the advantages of both digital and conventional printing methods. Hybrid presses typically feature a combination of flexographic printing, offset printing, and digital printing, offering flexibility and the ability to handle a variety of job types with greater efficiency.

The growing demand for hybrid press configurations in industries such as label printing, flexible packaging, and narrow-web printing has led to an increased focus on optimizing these presses for better performance. As hybrid presses integrate digital printing with traditional methods, the adaptation of LED curing systems becomes crucial to ensure seamless production across different technologies.

Benefits of Integrating LED Curing with Hybrid Presses

- Improved Print Quality

LED UV curing systems deliver high-quality prints with vibrant colors and sharp details. The instant curing process prevents the ink from smearing or becoming absorbed into the substrate, ensuring that the print quality remains crisp and clear. This is especially important for applications such as label printing and flexible packaging, where high-quality graphics and fine details are essential. - Faster Production Speeds

One of the key advantages of LED curing systems is the speed at which they can cure inks. In hybrid presses, this instant drying ability allows for faster turnaround times, reducing bottlenecks and increasing overall productivity. Hybrid printing presses equipped with LED curing systems can print multiple job types in quick succession, without the need for lengthy drying times. - Energy Efficiency

With LED UV curing, printing operations can significantly reduce their energy consumption. Hybrid presses that utilize LED curing systems benefit from lower operating costs due to the energy-efficient nature of the technology. Additionally, LED lamps have a longer lifespan compared to traditional UV lamps, meaning fewer replacements are needed, further reducing maintenance costs. - Versatility with Substrates

Hybrid presses often handle a wide range of substrates, from paper and cardboard to films and plastics. LED UV curing systems are highly adaptable and can cure inks on virtually any substrate, even those that are sensitive to heat. This flexibility makes LED curing an ideal solution for hybrid printing presses, which are frequently used for labels, flexible packaging, and narrow-web printing applications. - Reduced Environmental Impact

LED UV curing systems are a more sustainable option than traditional UV curing lamps. The reduced heat emission means that less energy is needed to maintain optimal printing temperatures, while the lower consumption of energy and reduced production of ozone contribute to a cleaner and more eco-friendly printing process. This is particularly important in industries where environmental concerns are a high priority, such as food and beverage packaging.

Adapting LED Curing Systems for Hybrid Presses

To fully capitalize on the benefits of LED curing in hybrid press configurations, it’s essential to consider how the system can be adapted to work seamlessly with the different printing technologies used in hybrid presses. Here are some important factors to consider when integrating LED curing systems into a hybrid printing press:

- Power and Wavelength Requirements

LED curing systems are available in different power ratings and wavelengths, depending on the type of ink being used. For instance, some LED systems are optimized for curing specific types of UV inks, such as those used in flexographic printing or narrow-web applications. When adapting LED curing technology for a hybrid press, it’s important to choose the correct power and wavelength to ensure the inks cure properly, without compromising print quality. - Press Configuration and Integration

Hybrid printing presses often involve a combination of digital and analog printing units, such as flexographic or offset presses. The LED curing system must be integrated into the press in a way that doesn’t interfere with the operation of these different technologies. A flexible installation process and the ability to adjust the position of the LED curing units can ensure that the system works efficiently across all types of printing units. - Increased Drying Efficiency

While LED UV curing systems are known for their instant drying capabilities, some hybrid presses may require additional adjustments to optimize the curing process. For example, it may be necessary to modify the ink formulations or add additional curing stations to achieve the desired curing effect across different substrates. Proper calibration and testing will ensure that the system delivers consistent results. - System Maintenance and Reliability

Hybrid presses are often used for high-volume production, so maintaining the LED curing system’s performance is critical. LED lamps are more durable than traditional UV lamps, but regular maintenance and cleaning are still necessary to ensure optimal curing efficiency. Routine checks of the curing units, ink systems, and press alignment will help prevent downtime and ensure the press operates smoothly.

Conclusion

The integration of LED UV curing systems into hybrid printing presses provides significant benefits for printers looking to enhance print quality, improve production efficiency, and reduce energy consumption. Whether in label printing, flexographic printing, or narrow-web printing, LED curing technology allows hybrid presses to offer superior results with faster turnaround times and lower operational costs.

As hybrid presses continue to gain traction across various industries, adapting LED curing systems to work effectively with these versatile configurations will be essential for staying competitive in the evolving printing market. By embracing this advanced technology, printers can achieve higher productivity, more sustainable operations, and exceptional print quality, ensuring they remain at the forefront of the industry.