How LED Curing Systems Reduce Maintenance and Operating Costs in Printing

The printing industry is constantly evolving with technology, and one of the most notable advancements in recent years is the introduction of LED curing systems. These systems have revolutionized the way prints are cured, offering a range of benefits, from energy efficiency to improved print quality. In this article, we explore how LED curing systems help reduce maintenance and operating costs, particularly in narrow web printing, flexographic printing, and UV printing.

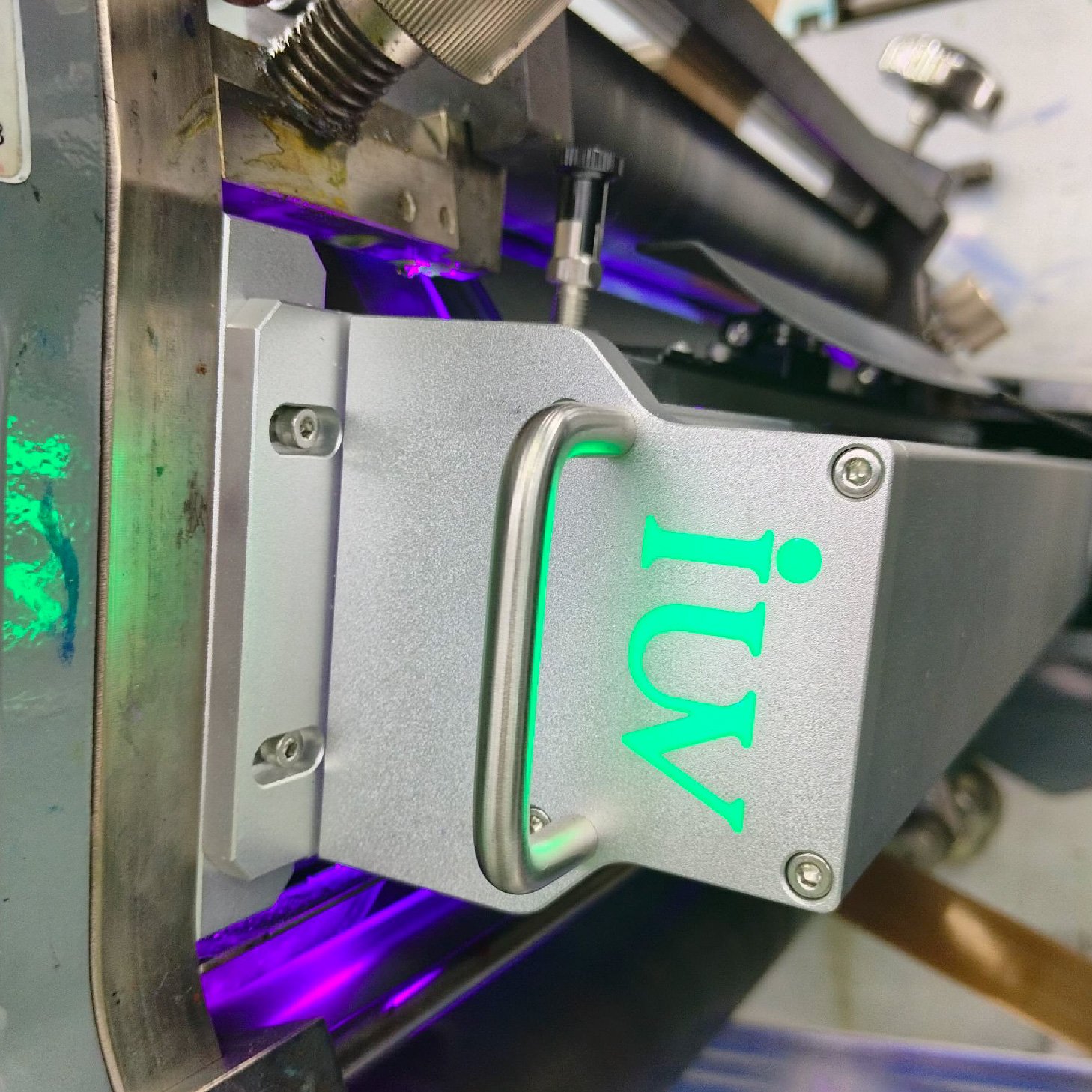

The Basics of LED Curing Technology

LED curing is a method of drying or curing inks and coatings using ultraviolet (UV) light emitted by light-emitting diodes (LEDs). Unlike traditional mercury vapor lamps used in UV curing systems, LED lamps produce less heat and consume less energy, making them an attractive option for printers looking to reduce their operating costs.

Energy Efficiency and Cost Reduction

One of the primary reasons LED curing systems have gained popularity in the printing industry is their energy efficiency. LED lamps use significantly less power than traditional UV lamps, which translates into lower electricity bills for print shops. Moreover, LED lamps have a much longer lifespan, which means fewer replacements are needed over time. This reduces the frequency of downtime, minimizes maintenance costs, and helps keep operations running smoothly.

With LED curing systems, printers can expect to save up to 70% in energy costs compared to traditional UV systems. This substantial reduction in energy consumption directly impacts a print shop’s bottom line, especially for businesses with high production volumes.

Reduced Maintenance Costs

Traditional UV curing systems require regular maintenance due to the wear and tear on mercury vapor lamps. These lamps have a limited lifespan, typically around 1,000 to 2,000 hours, after which they need to be replaced. Furthermore, UV lamps are prone to failure, which can lead to costly repairs and downtime.

LED curing systems, on the other hand, last much longer. The typical lifespan of an LED lamp can range from 10,000 to 20,000 hours, depending on the brand and usage. This extended lifespan results in fewer replacements and less frequent maintenance. Additionally, LED lamps do not require the frequent cleaning and calibration that traditional UV lamps do, which reduces the time and effort needed to maintain the system.

In the case of narrow web printing and flexographic printing, which often involve high-speed production and frequent press runs, the reduced maintenance demands of LED curing systems are particularly beneficial. With fewer interruptions for maintenance and lamp replacements, printers can maximize their production efficiency and reduce operational downtime.

Improved Print Quality and Consistency

LED curing systems also help improve print quality, further contributing to cost savings. One of the key advantages of LED curing is its ability to cure inks and coatings more precisely and consistently. LED lamps emit a focused spectrum of UV light, which allows for more uniform curing across the entire print. This precision leads to better color accuracy, sharper details, and more consistent results on a wide range of materials.

For flexographic printers and narrow web printers, achieving consistent print quality is crucial to meeting client expectations and avoiding rework. With LED curing systems, printers can produce high-quality prints consistently, reducing waste and the costs associated with defective prints.

Faster Curing and Increased Production Speeds

The faster curing speed of LED technology can also contribute to operational cost savings. LED lamps cure inks almost instantly, allowing for faster drying times and quicker turnaround times. This is especially valuable in high-volume printing environments, such as narrow web and flexographic printing, where speed is crucial.

With faster curing times, printers can increase their production speeds, which means more jobs can be completed within the same time frame. This increased throughput leads to higher profitability and more efficient use of labor and resources.

Environmental Benefits

LED curing systems are also more environmentally friendly than traditional UV curing systems. Because they consume less energy and have a longer lifespan, they generate less electronic waste. Additionally, LED lamps do not contain harmful mercury, which is commonly found in traditional UV lamps. This reduces the environmental impact of the printing process, which is becoming an increasingly important consideration for many businesses and consumers alike.

In the context of narrow web and flexographic printing, where large quantities of printed material are often produced, adopting energy-efficient LED curing systems can significantly reduce the environmental footprint of a printing operation.

Compatibility with a Range of Inks and Substrates

LED curing systems are versatile and can be used with a wide range of inks and substrates. This includes UV inks, which are commonly used in flexographic and narrow web printing. The ability to cure a variety of inks means that LED curing systems can be used in different printing applications, from labels to packaging, without compromising print quality or performance.

Furthermore, LED curing is compatible with a variety of substrates, including non-porous materials such as films, foils, and plastic substrates, which are commonly used in the packaging industry. This flexibility allows print shops to broaden their service offerings and cater to a wider range of clients, which can lead to increased sales and revenue.

Conclusion

The shift to LED curing systems in the printing industry is a game-changer, especially for narrow web, flexographic, and UV printing applications. From energy savings to reduced maintenance costs and improved print quality, the benefits of LED curing technology are clear. By embracing this advanced curing method, printers can reduce their operational costs, increase productivity, and offer higher-quality products to their clients.

As the demand for more sustainable and cost-effective solutions grows, LED curing systems are likely to become the standard in the printing industry, providing a competitive edge for businesses that adopt this technology early. Whether you’re printing labels, packaging, or other materials, switching to LED curing can be a smart investment that pays off in both the short and long term.