The printing industry is undergoing a dramatic transformation, driven by advancements in technology. Among the most groundbreaking developments is the introduction of LED curing systems, which are reshaping the future of printing. These systems have found their way into various printing methods, including label printing, flexographic printing, and narrow-web printing. The integration of LED UV curing not only enhances print quality but also improves efficiency and sustainability, aligning perfectly with the objectives of Industry 4.0.

The Rise of LED UV Curing Technology

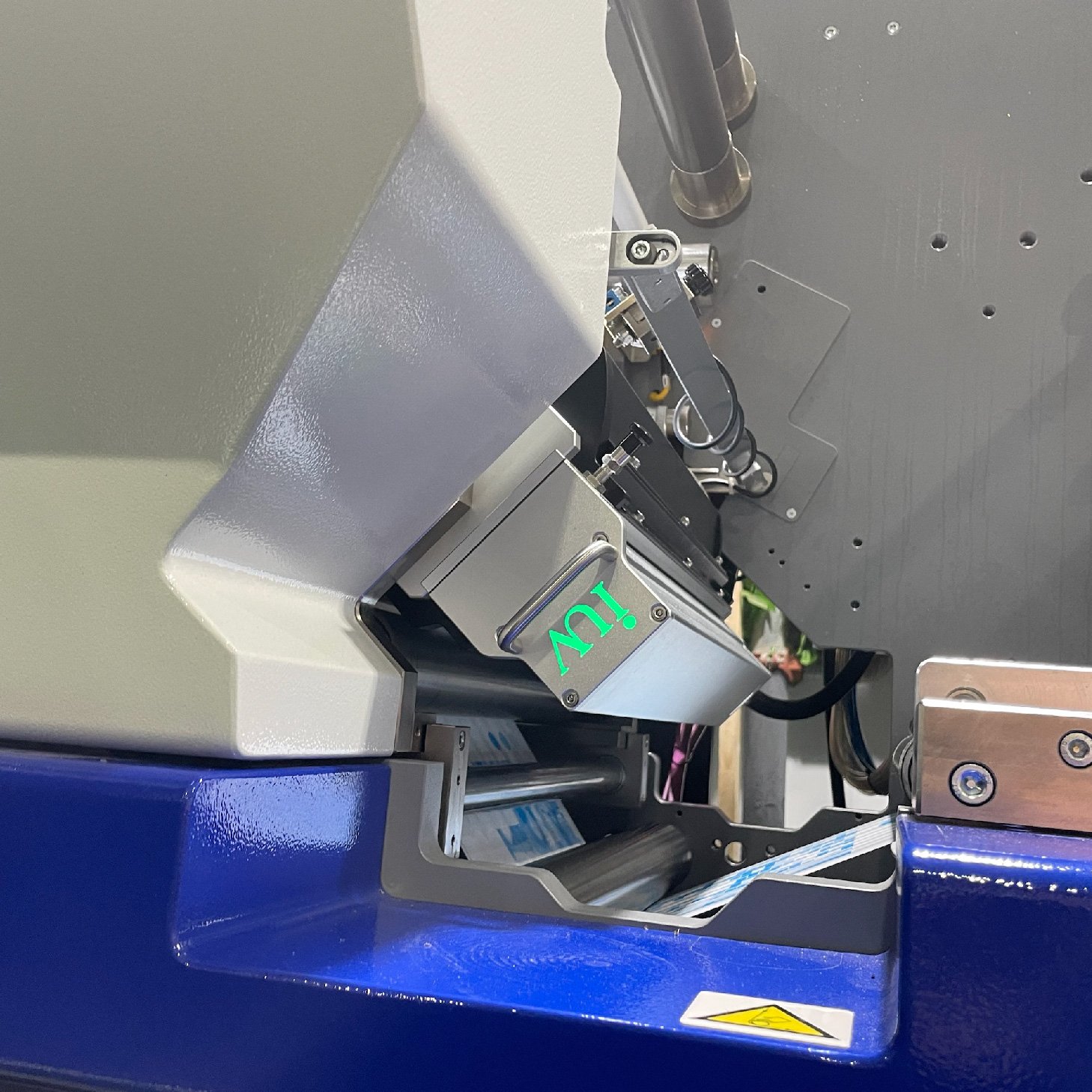

LED UV curing technology has emerged as a game-changer in the printing world. Traditionally, curing inks in printing processes required the use of mercury vapor lamps, which emitted a significant amount of heat and consumed a lot of energy. LED curing systems, in contrast, use light-emitting diodes to cure inks and coatings, offering multiple advantages over conventional methods.

One of the most notable benefits is energy efficiency. LED lamps consume significantly less energy compared to their mercury counterparts, reducing operational costs and improving the overall environmental footprint of the printing process. Additionally, LED UV curing systems have a longer lifespan, requiring less frequent replacement and reducing downtime.

Another key advantage is the precise control over curing. LED systems can be tailored to specific wavelengths, ensuring the optimal curing of inks and coatings for various substrates. This level of control contributes to higher print quality and consistency, especially important in industries like label printing and flexible packaging.

LED Curing in Label Printing

Label printing is one area where LED UV curing has shown impressive results. With the demand for high-quality, durable labels growing across industries, LED curing offers a solution that delivers both performance and speed.

In label printing, where fast drying and resistance to smudging are critical, LED curing technology offers the advantage of instant drying. This enables higher production speeds, allowing printers to meet tight deadlines while maintaining top-notch quality. Additionally, LED curing helps to reduce the need for additional post-processing, such as UV coating or varnishing, streamlining the entire printing workflow.

The versatility of LED curing is also beneficial when dealing with various substrates, such as paper, films, and synthetic materials. This capability is especially valuable in the growing field of flexible packaging, where manufacturers are constantly seeking better ways to print on non-porous materials.

LED UV Curing in Flexographic Printing

Flexographic printing, a method commonly used for packaging, has also embraced LED UV curing technology. This technique utilizes flexible plates to transfer ink onto a variety of substrates, and when combined with LED curing, it offers several significant advantages.

Flexographic printers can achieve higher speeds and better print quality with LED curing. The rapid curing process eliminates the need for excessive drying time, enabling the production of more prints in a shorter amount of time. This increased throughput is particularly valuable in high-volume printing environments like corrugated packaging and flexible packaging.

LED UV curing also improves the precision of color reproduction, which is essential for maintaining brand consistency and meeting customer expectations. With traditional curing methods, flexographic printers often faced challenges with ink adhesion and color stability. LED curing mitigates these issues by providing consistent, uniform curing across different substrates and ink formulations.

Narrow-Web Printing and LED Curing

Narrow-web printing, which involves printing on smaller rolls of material, is another application where LED UV curing technology is making a significant impact. This method is commonly used for labels, tags, and small-format packaging. The use of LED UV curing in narrow-web printing enhances the process by increasing speed and efficiency while maintaining high-quality output.

One of the main advantages of LED curing in narrow-web printing is its ability to cure inks instantly. Traditional curing methods require longer drying times, which can create bottlenecks in production. With LED systems, however, printers can reduce curing times to a matter of seconds, leading to faster turnaround times and improved productivity.

Additionally, narrow-web printers can take advantage of the ability to cure a wide range of inks, including UV inks, solvent-free inks, and water-based inks. This flexibility allows printers to adapt to changing customer needs, offering a variety of solutions without compromising on quality or performance.

The Environmental Impact of LED Curing

As the printing industry moves toward more sustainable practices, LED curing technology plays a pivotal role in reducing the environmental impact of printing operations. Traditional UV curing systems often rely on mercury vapor lamps, which are energy-intensive and contain hazardous materials. LED curing systems, on the other hand, are free from mercury and produce less heat, reducing the need for additional cooling in the printing environment.

Moreover, LED systems consume less power, reducing the overall carbon footprint of printing operations. The longer lifespan of LED lamps further reduces waste, as printers do not need to replace them as frequently. This makes LED UV curing an ideal choice for companies looking to minimize their environmental impact while maintaining high-quality output.

LED Curing and Industry 4.0

The integration of LED curing systems aligns perfectly with the principles of Industry 4.0, a new era of industrial automation and data exchange. Industry 4.0 focuses on the use of smart technologies, IoT devices, and data analytics to optimize production processes and improve efficiency. LED curing systems fit seamlessly into this vision by providing real-time feedback and control over the curing process.

With the ability to adjust and monitor curing parameters remotely, printing operations can make data-driven decisions that improve performance and reduce waste. This level of automation and control is essential for staying competitive in a fast-paced industry.

Furthermore, the reduced energy consumption and longer lamp lifespan of LED curing systems contribute to a more sustainable production process, which aligns with the broader goals of Industry 4.0 to promote sustainability and resource efficiency.

Conclusion

LED UV curing technology has become a cornerstone of the next generation of printing. By offering faster curing times, energy efficiency, and improved print quality, LED curing systems are transforming label printing, flexographic printing, narrow-web printing, and other applications. As the printing industry embraces these innovations, LED curing will continue to play a key role in shaping the future of the industry, driving it toward greater sustainability, efficiency, and performance.

Incorporating LED UV curing systems not only enhances the print process but also helps businesses meet the demands of Industry 4.0. As manufacturers continue to explore the potential of this cutting-edge technology, the future of printing looks brighter than ever.