Selecting the appropriate UV curing system for your flexo press is crucial to achieving high-quality, efficient, and sustainable printing operations. With advancements in UV LED technology, understanding the differences between traditional mercury vapor lamps and modern LED UV systems becomes essential for making informed choices that align with your production needs. This guide covers key considerations for UV curing, emphasizing LED UV innovation, and explains how to optimize your setup for label, flexographic, plate, and narrow-web printing.

Understanding UV Curing: An Overview

Ultraviolet (UV) curing is a rapid drying process that uses ultraviolet light to instantly polymerize inks, coatings, or adhesives. The result is a durable, glossy finish that resists scratches, chemicals, and environmental stressors. UV curing offers many advantages over traditional solvent-based systems, including lower emissions, faster processing times, and better print quality.

Traditional UV systems operate with mercury vapor lamps, which are powerful but come with drawbacks like high energy consumption, heat generation, and limited lifespans. Recent developments have introduced UV LED systems, which deliver targeted, energy-efficient curing, reduce heat impact, and extend operational longevity.

Key Factors in Choosing the Right UV System

- Type of Printing Process

- Label Printing: Requires flexibility in speed, precise control of curing to prevent dot gain, and compatibility with thin substrates. UV LED systems are particularly advantageous due to their instant on/off capability and low heat emission, ideal for heat-sensitive label stocks.

- Flexo Printing: Demands consistent curing across various inks and substrates. Both mercury vapor and LED UV systems can be effective here, but LEDs provide immediacy, energy savings, and reduced maintenance, which benefit high-volume operations.

- Plate and Screen Printing: Involves demanding curing requirements, especially for detailed designs. LED UV’s focused wavelength and instant startup enable excellent control over curing parameters, reducing waste and rework.

- Narrow Web Printing: Often involves intricate designs and thin materials. The compact nature of UV LED systems fits well into narrow web presses, allowing for tight integration and customization.

- Type of Ink and Coatings

Selecting a UV curing system depends on the inks used. LED UV inks are formulated for compatibility with LED light sources, with specific photoinitiators that absorb at targeted wavelengths. Mercury vapor systems can cure a wider range of inks but may require different lamp configurations and heat management strategies.

- Operational Efficiency and Cost

LED UV systems typically exhibit lower energy consumption, faster startup times, and longer lifespans for lamps—reducing ongoing operational costs. Their instant on/off capability minimizes waste and enables better production scheduling. The initial investment in LED UV systems is higher but often offset by savings over the equipment’s life span.

- Environmental and Safety Considerations

LED UV lighting produces no mercury, avoiding hazardous waste disposal issues associated with traditional lamps. The lower heat output minimizes substrate warping and enhances operator safety. Additionally, decreased volatile organic compound emissions contribute to a greener production process.

- Speed and Reaction Time

For high-speed presses, the rapid cure offered by UV LEDs supports increased production throughput. Their instant light emission allows for immediate curing, enabling faster press speeds and reducing bottlenecks.

- Substrate Compatibility and Heat Management

Heat-sensitive substrates, such as thin films and flexible labels, benefit significantly from LED UV’s minimal heat emission. This improves substrate stability and prevents warping or deformation during curing.

Advanced Features of LED UV Systems

- Wavelength Flexibility: Many LED systems offer selectable wavelengths, allowing customization for specific inks or coatings. This flexibility enhances curing efficiency and ink bonding.

- Low Power Consumption: By converting more electrical energy directly into usable UV light, LEDs consume less power, contributing to lower energy bills and sustainability goals.

- Longer Lamp Life: An LED UV lamp can last upwards of 20,000 hours, drastically reducing downtime and maintenance costs compared to mercury vapor lamps.

- Instant On/Off: LED systems can be turned on or off instantly, facilitating quick changeovers, reducing waste, and enabling demand-driven production cycles.

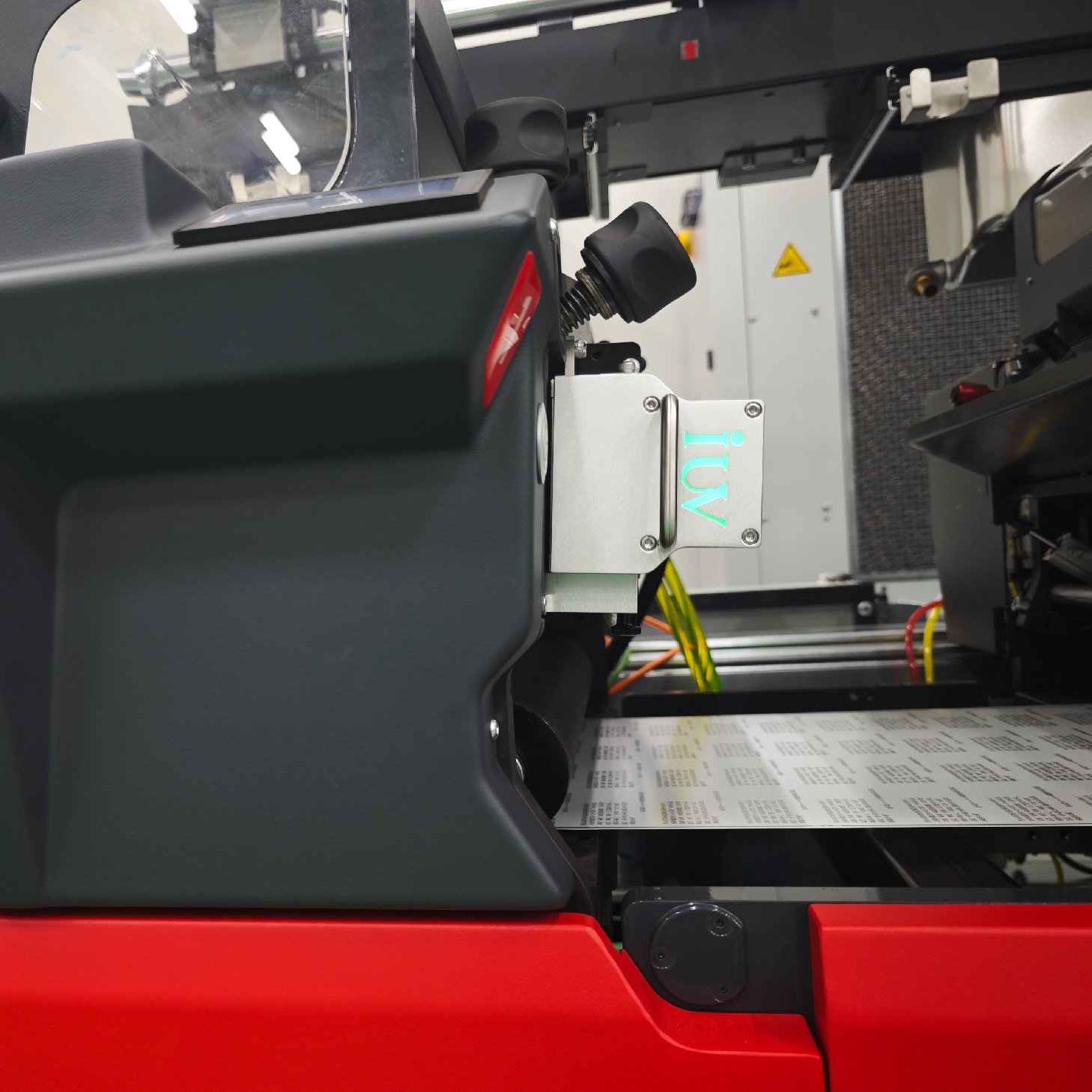

Integrating LED UV into Your Flexo Press

Successful integration involves assessing your existing press architecture, substrate types, and production goals. Many modern flexo presses are designed with modular UV LED modules that can be retrofitted or built-in from the ground up.

Coordination with suppliers is vital to ensure system compatibility, optimal wavelength selection, and effective heat management. Proper calibration and testing improve curing consistency, ink adhesion, and overall print quality.

Future Trends and Considerations

The trend towards more sustainable, energy-efficient printing processes favors UV LED technology. Advances continue to improve curing speeds, wavelength flexibility, and ink formulations, expanding the range of applications. Additionally, ongoing research supports broader substrate compatibility and enhanced curing uniformity.

Choosing the right UV curing system involves balancing initial investment with long-term operational benefits. A comprehensive evaluation of your specific printing needs, substrate types, and production scale will guide you toward the optimal solution that leverages the strengths of UV LED technology for label, flexo, plate, or narrow-web printing.

In summary, UV LED systems stand out as the most adaptable, energy-efficient, and environmentally friendly option for modern flexo presses. Their instant curing, minimal heat emission, and reduced maintenance make them a compelling choice for both current and future printing demands.