In the competitive world of print production, incorporating UV curing technology has revolutionized the way inks adhere to substrates. UV curing offers remarkable advantages for various printing methods, including flexography, letterpress, and narrow-web printing, ensuring superior ink adhesion and high-quality output.

The Role of UV Curing in Modern Ink Adhesion

UV curing systems utilize ultraviolet light to rapidly polymerize inks and coatings. This transformation from liquid to solid occurs within seconds, producing an instant bond between ink and substrate. For label printing, especially in flexographic and letterpress setups, this quick curing process minimizes smudging and enhances durability.

Good ink adhesion is pivotal in label applications, where exposure to moisture, chemicals, or handling can cause inks to peel or fade. UV-curable inks, when combined with UV curing systems, create a tough, chemical-resistant layer that maintains clarity and vibrancy over time.

Advantages of UV Curing in Narrow-Web and Specialty Printing

In narrow-web and label printing, precision and speed are fundamental. UV curing systems support these demands by allowing immediate handling and finishing post-printing, reducing bottlenecks in production flow. Their ability to cure inks on various substrates—glass, plastic, paper—broadens the scope of application.

Furthermore, UV curing reduces solvent emissions, making it an environmentally friendly choice. For narrow-width printing equipment, LED UV systems are especially advantageous because they consume less energy and generate less heat, thus protecting delicate substrates like thin films and flexible plastics.

How LED UV Technology Elevates Print Quality

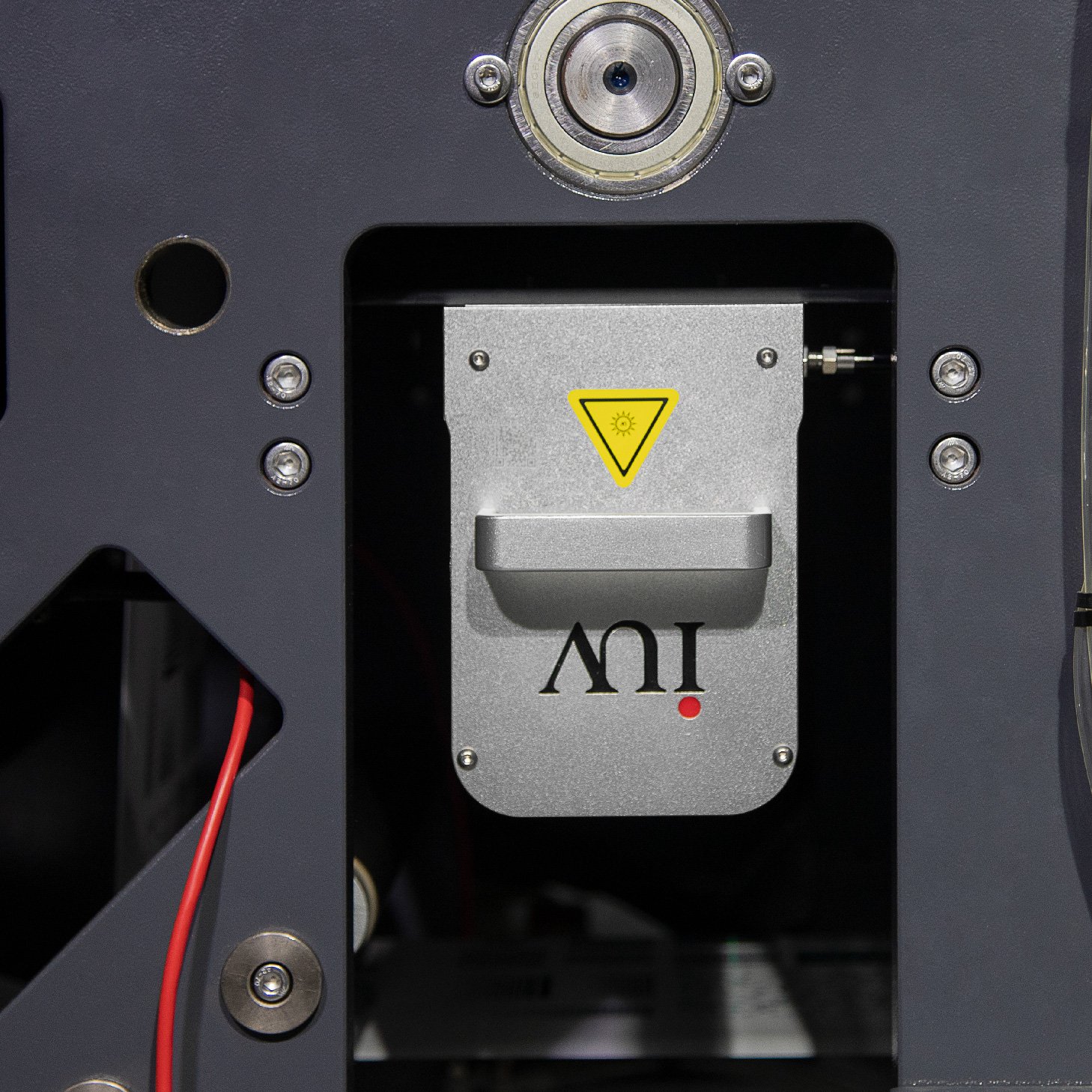

LED UV systems represent a significant evolution in curing technology. Unlike traditional UV lamps, LEDs emit a narrow wavelength spectrum, which can be precisely controlled. This targeted approach results in faster curing times, less heat generation, and extended equipment lifespan.

LED UV’s ability to instantaneously cure inks accelerates production speeds without compromising quality. It also allows for curing of thick or multi-layered inks uniformly, improving print crispness and color density. Since LEDs produce less heat, they are ideal for heat-sensitive substrates used in flexible packaging and specialty label printing.

Improved Ink Adhesion with LED UV and UV Curing Systems

The adhesion of inks in flexo and letterpress printing depends heavily on the curing process. UV and LED UV systems ensure that the ink’s polymer components cross-link effectively with the substrate, creating a durable, resistant layer.

These systems also aid in preventing common adhesion failures such as blocking, scuffing, or smudging. The rapid curing locks the ink particles in place instantly, reinforcing the integrity of the print, especially under demanding conditions such as high humidity or exposure to chemicals.

Optimizing Print Quality with UV Curing

The interplay of ink formulation, substrate selection, and curing technology is vital. UV-curable inks are formulated to maximize adhesion and vibrancy, while UV curing systems are calibrated to ensure complete polymerization.

In flexible packaging and label printing, the precise control of curing intensity and duration can significantly improve gloss, sharpness, and color fidelity. Proper curing reduces the risk of ink transfer problems during finishing or stacking, leading to cleaner, more appealing products.

Sustainability and Efficiency Benefits

One of the most appealing features of modern UV curing systems is their contribution to sustainability. They eliminate the need for volatile organic compounds (VOCs), reducing environmental impact and health risks for operators.

LED UV systems amplify these benefits with lower energy consumption and longer lifespans. They enable printers to meet stricter environmental standards while maintaining high-quality standards for ink adhesion and print finish.

Practical Considerations for Implementing UV Curing Technologies

Choosing the right UV curing system requires understanding the specific needs of your printing operation. Factors include substrate types, production speeds, and environmental regulations.

For flexible and narrow-web printers, LED UV modules are increasingly preferred due to their compact size, less heat emission, and energy efficiency. They are compatible with a broad range of inks and substrates, providing versatile solutions for various printing demands.

Conclusion: Transforming Print Quality with UV and LED UV Systems

The integration of UV curing technology—especially LED UV—has reshaped how prints adhere and exhibit clarity. The rapid, efficient curing promotes exceptional ink adhesion, durability, and vibrant visual effects. For label and flexible packaging printers, investing in UV curing systems is a strategic move to elevate print quality, boost productivity, and promote sustainable practices.

As the industry continues to evolve, these systems will remain at the forefront of innovation, ensuring that printed products meet and exceed the highest standards of quality and environmental responsibility.