The printing industry is constantly seeking ways to enhance efficiency and reduce its environmental footprint. One of the most impactful advancements in this pursuit is the widespread adoption of UV curing systems. These innovative technologies offer significant energy savings, transforming how labels, flexible packaging, and other print products are manufactured. Moving beyond traditional drying methods, UV curing utilizes ultraviolet light to instantly cure inks and coatings, leading to a cascade of benefits.

For narrow web printers, especially those focused on label and packaging production, the advantages are particularly pronounced. Traditional drying methods often rely on heated air, which is an energy-intensive process. Large volumes of air need to be heated and then exhausted, carrying away both heat and valuable energy. This contributes to higher operational costs and a larger carbon footprint. UV curing, by contrast, uses light energy to initiate a photochemical reaction. This process is highly targeted and happens instantaneously, meaning energy is only applied when and where it’s needed.

The core of UV curing technology lies in specially formulated inks and coatings that contain photoinitiators. When exposed to UV light of specific wavelengths, these photoinitiators absorb the energy and generate free radicals or cations. These highly reactive species then initiate a rapid polymerization process, cross-linking the ink or coating molecules and transforming them from a liquid state into a solid, durable film almost instantly. This is a stark contrast to solvent-based or water-based inks, which require evaporation of the liquid vehicle to dry. Evaporation demands substantial heat and time, often leading to bottlenecks in production and increased energy consumption.

Consider the energy dynamics. A conventional drying oven might consume several kilowatts of power to heat air, which is then circulated. In many cases, this heated air needs to be exhausted to prevent ink from smudging or to remove volatile organic compounds (VOCs). This continuous expenditure of energy to heat and exhaust air represents a significant inefficiency. UV curing systems, particularly those employing LED UV technology, operate with much lower power consumption. A modern LED UV lamp array might consume a fraction of the power of a traditional mercury vapor lamp or a hot air dryer, while delivering superior curing results.

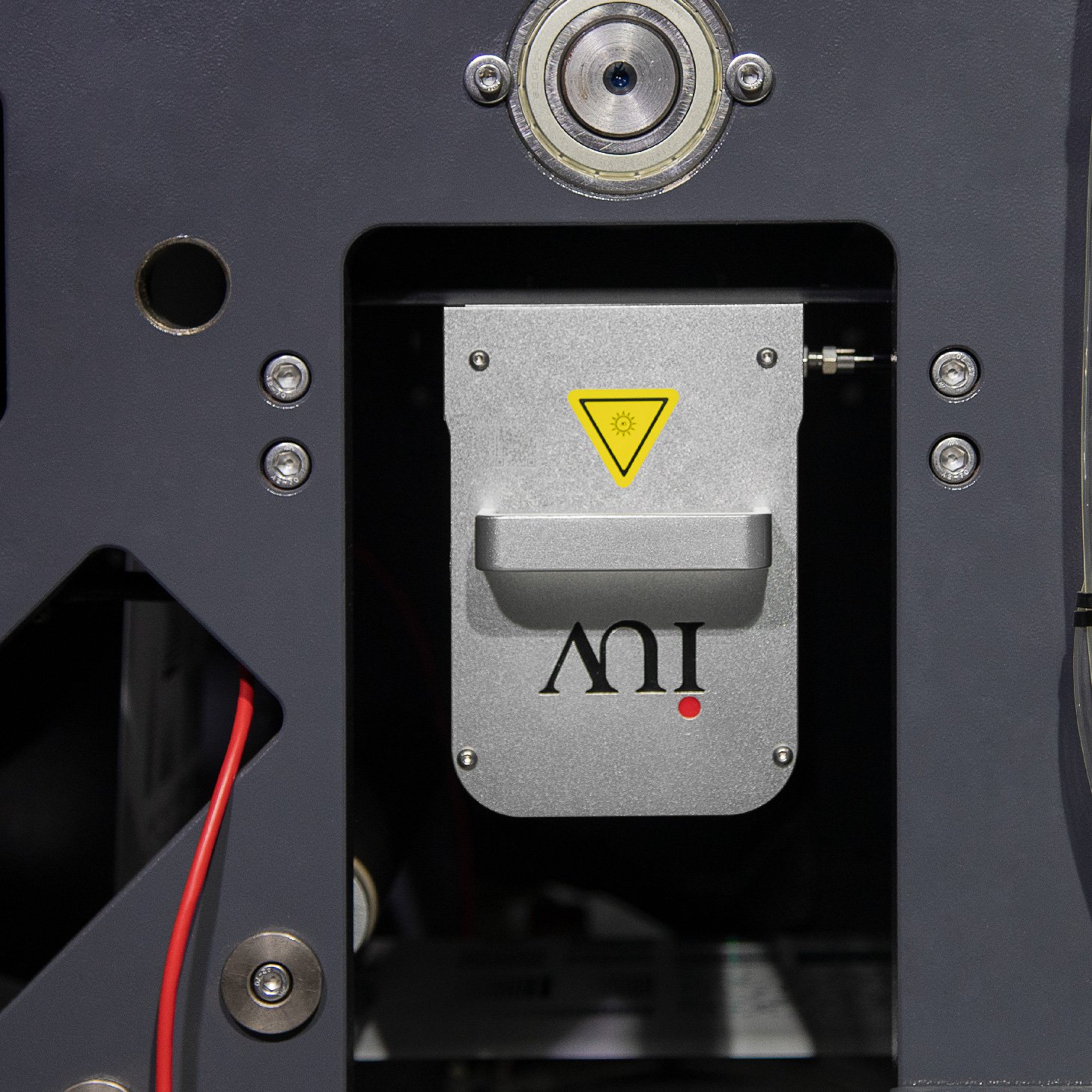

The shift towards LED UV technology has further amplified the energy-saving potential of UV curing. Unlike older mercury vapor lamps, which generate heat as a byproduct and require considerable energy to operate, LEDs are highly efficient light sources. They emit light in narrow, specific wavelength bands that are perfectly matched to the absorption spectrum of the photoinitiators in the inks and coatings. This precision means less wasted energy. Furthermore, LEDs have a much longer lifespan than traditional lamps, reducing maintenance costs and waste. They also operate at much lower temperatures, which is beneficial for heat-sensitive substrates commonly used in narrow web printing, such as thin films and certain papers. This opens up new possibilities for printing on a wider range of materials without concerns about heat distortion or degradation.

The impact on operational efficiency is also substantial. Because UV curing is an instantaneous process, there is no need for lengthy drying tunnels or cooling sections. This allows for higher printing speeds, as the ink is cured as soon as it passes under the UV lamps. This means a shorter web path, smaller press footprint, and increased throughput. For businesses operating in competitive markets like narrow web label printing, this increase in productivity translates directly to cost savings and improved delivery times.

Environmental benefits extend beyond direct energy consumption. Traditional solvent-based inks release VOCs into the atmosphere, which can contribute to air pollution and pose health risks. UV-curable inks and coatings are typically 100% solids or have very low VOC content, meaning that during the curing process, there is little to no evaporation of solvents. This results in cleaner air emissions and a safer working environment for operators. This aligns with increasing regulatory pressure and consumer demand for more sustainable printing practices.

In flexographic printing, a common method for narrow web applications, UV curing systems have become standard for many high-quality jobs. They allow for crisp dot definition and vibrant color reproduction, often surpassing the quality achievable with older drying technologies. The ability to apply multiple UV-cured ink layers sequentially without interference or smudging is also a significant advantage, enabling complex multi-color designs and special effects.

Offset printing, while historically associated with heatset or sheetfed drying, is also increasingly incorporating UV curing, especially in commercial and packaging segments. UV-offset inks offer excellent rub resistance and gloss, making them ideal for high-impact printed materials. The instant curing allows for immediate stacking of printed sheets without the need for anti-offset powders, which can detract from print quality and create waste.

The investment in UV curing technology, while requiring initial capital outlay, pays dividends through reduced energy bills, increased production speeds, lower waste, and the ability to print on a wider range of substrates. The enhanced durability and resistance properties of UV-cured inks and coatings also mean fewer rejected jobs due to print defects or poor performance in the final application.

In summary, UV curing systems, particularly those powered by advanced LED technology, are not just an incremental improvement; they represent a fundamental shift towards more sustainable and efficient printing operations. They empower printers in the narrow web, flexographic, and offset sectors to reduce their energy consumption, minimize environmental impact, and achieve higher levels of productivity and print quality. Embracing this technology is a strategic move for any printing business looking to thrive in an increasingly cost-conscious and environmentally aware market.