The printing industry is constantly evolving. Businesses seek more sustainable and efficient solutions. This is where UV curing technology shines. It offers a greener path for various printing methods. Let’s explore how UV curing is revolutionizing printing.

What is UV Curing?

UV curing uses ultraviolet light. This light initiates a photochemical process. It instantly dries or cures inks, coatings, and adhesives. Traditional methods often rely on heat or solvents. These can release Volatile Organic Compounds (VOCs). UV curing, especially with LED UV, significantly reduces or eliminates these emissions. This makes it an environmentally friendly choice.

Eco-Friendly Benefits of UV Curing

The primary eco-benefit is reduced VOCs. This leads to cleaner air and a healthier workplace. Less energy consumption is another advantage. UV lamps, particularly LEDs, are highly efficient. They use less power than conventional lamps. This translates to lower energy bills and a smaller carbon footprint.

UV curable inks and coatings often have a longer shelf life. This means less waste from expired materials. The instant curing also means less downtime. Presses can run faster and more continuously. This boosts productivity and reduces waste from misprints. The cured inks are also highly durable. They resist fading and scratching. This means printed products last longer, reducing the need for reprints.

UV Curing in Label Printing

Label printing is a major area benefiting from UV curing. Narrow web flexographic printing is very popular for labels. UV inks are ideal for this application. They cure instantly under UV lamps positioned along the press. This allows for very fast printing speeds.

The vibrant colors and sharp details achievable with UV inks are excellent for labels. Labels need to grab attention and convey information clearly. UV curing ensures high print quality. It handles intricate designs and fine text with precision.

Furthermore, the durability of UV cured labels is a significant plus. They can withstand harsh conditions. This includes exposure to moisture, chemicals, and abrasion. Think of labels on cleaning products or outdoor equipment. UV curing ensures they remain legible and attractive.

UV Curing in Flexographic Printing

Flexographic printing, or flexo, is another field transformed by UV technology. It’s used for packaging, commercial printing, and of course, labels. UV flexo inks offer a vast color gamut. They provide excellent adhesion to a wide range of substrates. This includes plastics, foils, and paper.

The instant curing in flexo prevents ink from smudging. It also stops ink from transferring between layers. This is crucial when printing multiple colors or applying coatings. The high gloss and matte finishes possible with UV coatings add aesthetic appeal to printed products.

LED UV curing is particularly impactful in flexo. LED lamps are more energy-efficient and have a longer lifespan than mercury vapor lamps. They also generate less heat. This is beneficial for heat-sensitive substrates. The precise control over UV output with LEDs ensures consistent curing. This leads to repeatable high-quality results.

UV Curing in Offset Printing

Offset printing, also known as lithographic printing, is also embracing UV curing. Offset presses can be equipped with UV curing units. This allows for immediate drying of inks and coatings. This is a game-changer for offset.

Traditionally, offset inks dry by oxidation. This process is slow. It requires careful handling of printed sheets. UV offset printing eliminates this waiting time. Sheets can be handled, stacked, and finished immediately. This speeds up the entire production workflow.

UV offset inks offer superior rub resistance and color brilliance. They are also suitable for non-porous substrates like plastics and foils. These materials are challenging for conventional offset inks. The eco-friendly aspect of reduced VOCs is also a significant draw for offset printers looking to improve their environmental profile.

Narrow Web Printing and UV Curing

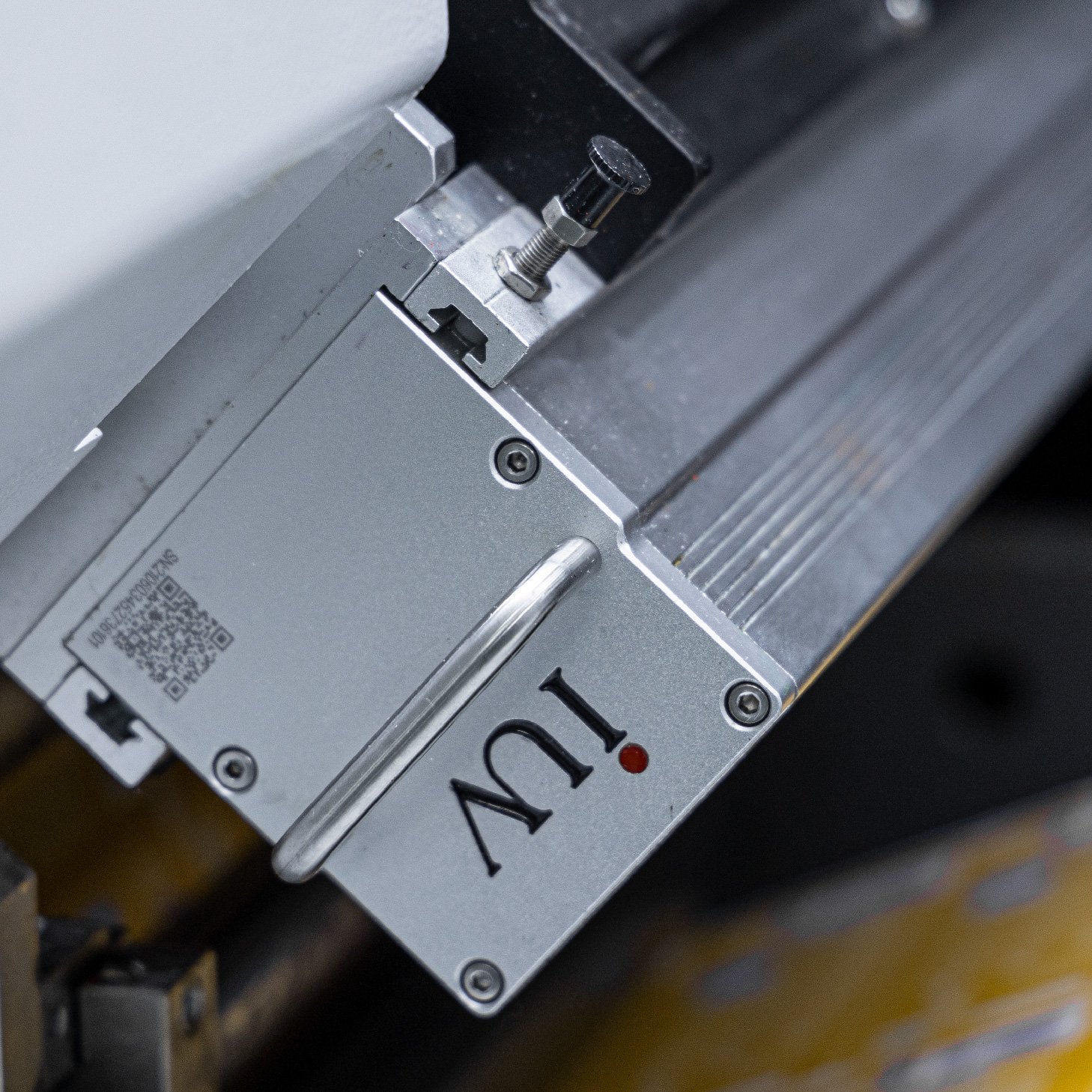

Narrow web printing focuses on smaller format printing. This is common for labels, packaging, and specialty items. UV curing is a natural fit for narrow web presses. The compact size of UV curing units means they can be easily integrated into narrow web machines.

The high speeds of narrow web presses demand fast drying. UV curing provides this instant drying capability. This prevents ink from offsetting onto the next layer or web. The ability to print on a variety of substrates is also key. Narrow web printers often handle diverse materials. UV inks and coatings offer excellent adhesion and performance across these different surfaces.

LED UV vs. Traditional UV Curing

While both offer environmental benefits over solvent-based systems, LED UV curing represents the next generation. Traditional UV curing often uses mercury vapor lamps. These lamps consume more energy. They also produce ozone and require more frequent replacement.

LED UV lamps are significantly more energy-efficient. They have a much longer operational life, reducing waste. They emit very little heat, which is crucial for delicate substrates. LED lamps also offer more consistent UV output. This leads to more reliable curing and better print quality over time. The environmental benefits are amplified with LED technology.

The Future is Bright and Green

The future of printing is undoubtedly greener. UV curing technology, especially LED UV, is at the forefront of this movement. It offers a compelling combination of environmental responsibility, efficiency, and quality. From vibrant labels to durable packaging, UV curing enhances every aspect of the print process.

As environmental regulations tighten and consumer demand for sustainable products grows, UV curing will become even more indispensable. Printers investing in this technology position themselves for success. They can meet the demands of a changing market. They can also contribute to a healthier planet. The shift towards UV curing is not just a trend; it’s a fundamental evolution in how we print. It’s a move towards a brighter, cleaner, and more sustainable printing future.