In the fast-paced world of label printing, where deadlines loom large and quality expectations are sky-high, the technology employed makes all the difference. Among the most transformative innovations in recent years is the widespread adoption of UV curing systems. These systems, particularly those leveraging advanced LED UV technology, are fundamentally reshaping how labels are produced, offering unparalleled gains in both production speed and end-product quality across various printing methods.

For narrow web printers, the advantages are particularly pronounced. Traditional printing often involves lengthy drying times for inks and coatings. This bottleneck directly impacts how many jobs can be completed in a given shift. UV curing, however, offers an instant solution. As ink passes under the UV lamps, it instantly solidifies, or “cures.” This means finished labels are ready for the next stage of finishing or packing almost immediately. No waiting, no smudging, just pure, unadulterated speed. This rapid turnaround is a game-changer for businesses that need to respond quickly to market demands or fulfill rush orders.

Flexographic printing, a workhorse in the label industry, benefits immensely from UV curing. Flexo presses are known for their efficiency and versatility, capable of handling a wide range of substrates from paper to plastic films. When combined with UV-curable inks, flexo printing reaches new heights of performance. The instant curing ensures that inks lay down precisely where they are intended, preventing bleed and halo effects that can mar print quality. This precision is crucial for intricate designs, fine text, and vibrant color reproduction that define premium labels. Furthermore, UV inks are often more durable and resistant to chemicals and abrasion than their conventional counterparts, leading to labels that not only look good but also withstand the rigors of the products they adorn.

Offset printing, while traditionally associated with sheet-fed applications, also finds a powerful ally in UV curing within the narrow web sector. UV offset inks cure instantaneously upon exposure to UV light. This allows for faster press speeds and the ability to print on a wider array of non-absorbent substrates, such as plastics and foils, which are common in high-end label applications. The sharp dot definition achieved with UV offset printing, coupled with the rapid curing, translates directly into superior image quality and enhanced visual appeal for finished labels. This means brands can present their products with a level of sophistication and clarity that captivates consumers at the point of sale.

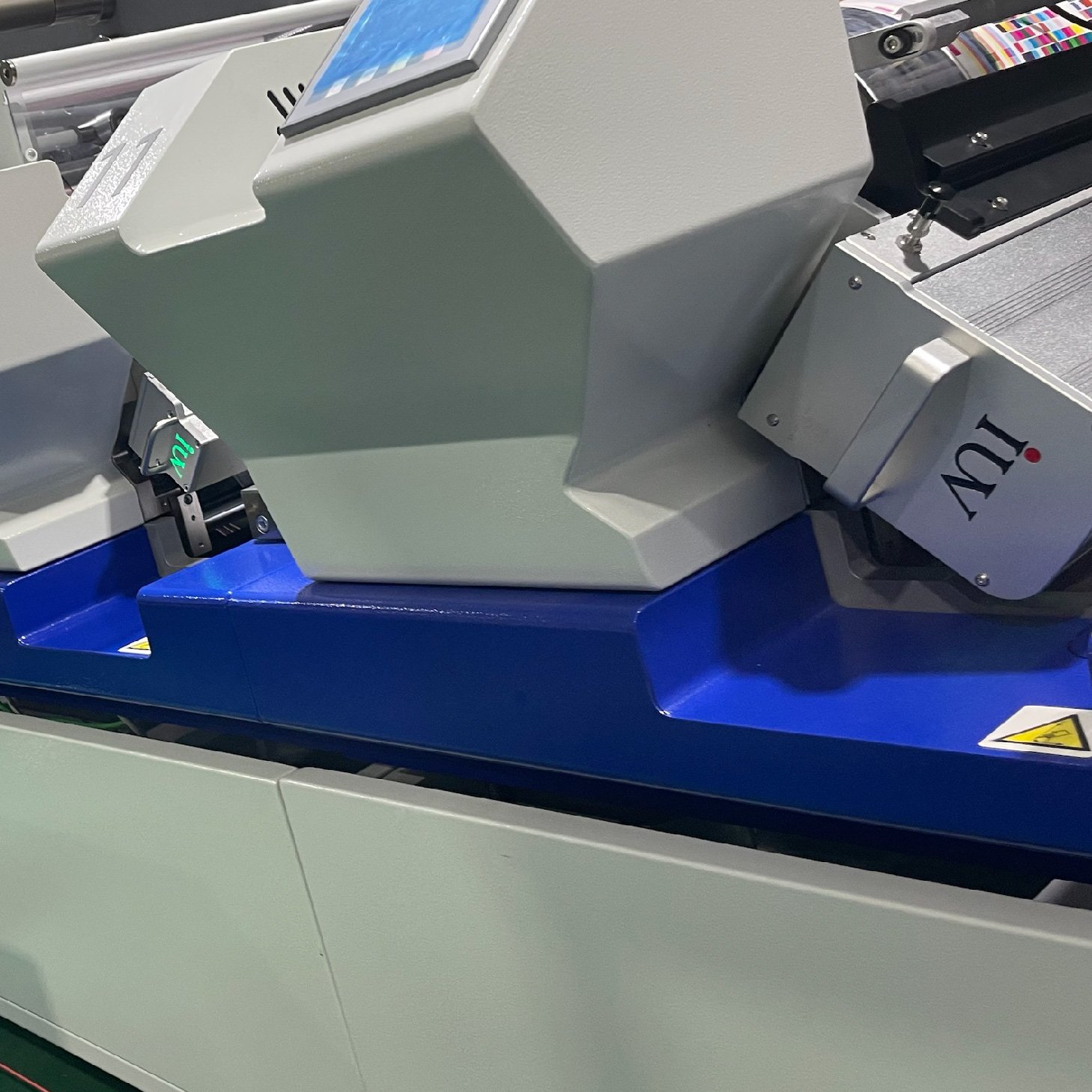

The advent of LED UV curing technology has further amplified these benefits. Unlike traditional mercury lamp UV systems, LED UV lamps offer a host of advantages. They consume significantly less energy, leading to substantial cost savings on electricity bills. They also generate less heat, which is critical when printing on heat-sensitive substrates, preventing warping or damage. LEDs have a much longer lifespan, reducing maintenance and replacement costs. Importantly, they provide a more consistent and controllable UV output, ensuring reliable and uniform curing across the entire print width, job after job. This consistency is paramount for achieving repeatable high quality.

For label printers, this translates into fewer waste sheets due to curing issues, reduced downtime for lamp replacements, and the ability to confidently tackle complex jobs with demanding specifications. The environmental benefits are also noteworthy. UV curing systems, especially LED, are more energy-efficient and often do not contain mercury, aligning with growing demands for sustainable printing practices.

The quality enhancements driven by UV curing are multifaceted. The instant solidification of inks means that colors remain vibrant and true, without the dulling effect that can occur with slow-drying conventional inks. The sharp, well-defined printed image is a direct result of the ink’s immediate curing before it has a chance to spread. This is particularly important for small text, fine lines, and halftones, where clarity is king. Moreover, UV-cured inks and coatings offer superior resistance properties. They are often more resistant to scratching, scuffing, fading, and chemicals. This durability ensures that the label remains intact and legible throughout the product’s lifecycle, from manufacturing and shipping to display and end-use. This increased robustness translates into fewer returned or rejected labels, saving businesses both time and money.

When considering the substrates used in label printing, UV curing opens up a world of possibilities. Conventional inks often require porous substrates to dry properly through absorption. UV-curable inks, however, cure through a photochemical reaction initiated by UV light. This means they can be applied effectively to a vast range of non-porous materials, including various plastics (PE, PP, PET), foils, and synthetic papers. This versatility allows for greater creative freedom in label design and enables the production of labels for products that might not be suitable for traditional printing methods. Think about labels for beverages, cleaning products, or cosmetics where water and chemical resistance is a must – UV curing is the ideal solution.

In summary, UV curing systems, especially with the efficiency and precision of LED technology, are not just an upgrade; they are a fundamental shift in label printing capabilities. They empower narrow web, flexo, and offset printers to achieve significantly faster production cycles. Simultaneously, they elevate the quality and durability of printed labels, meeting and exceeding the stringent demands of today’s competitive market. Embracing UV curing is a strategic move towards greater efficiency, superior output, and a more sustainable printing future.