Print durability is paramount. Whether you’re producing eye-catching labels or robust packaging, the final print needs to withstand daily wear and tear. Traditional curing methods have long been the standard. However, advancements in LED UV curing technology are now offering a superior solution. This innovative approach significantly enhances print durability and resistance to wear across various printing methods.

For label printers, durability means a product that looks good for its entire lifecycle. Think about wine bottles, cosmetic containers, or industrial chemical labels. These often face moisture, abrasion, and exposure to different environments. Enhanced durability ensures the brand message remains clear and intact. LED curing plays a key role here. It achieves this by creating a more robust and cross-linked ink film compared to older technologies.

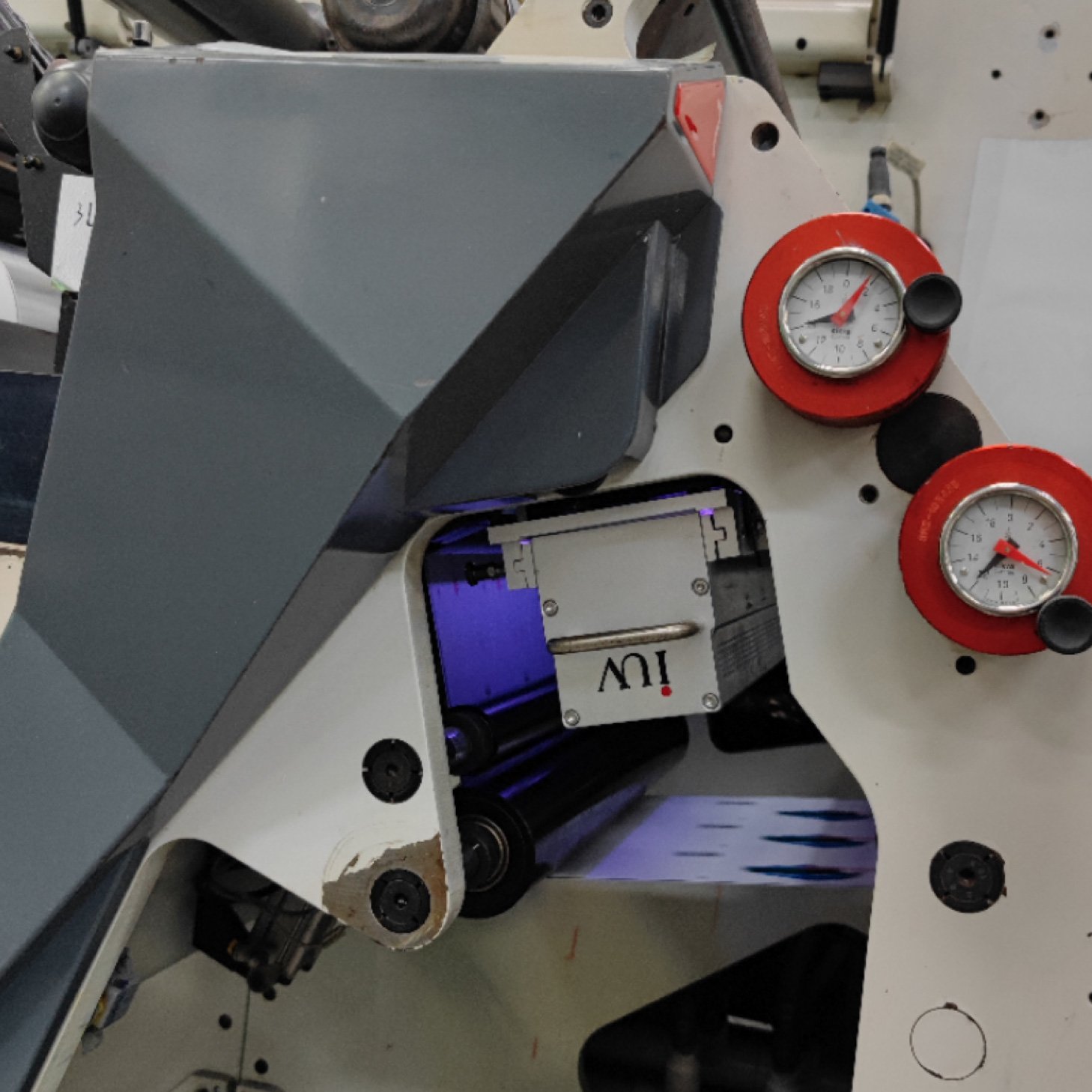

Flexographic printing, a workhorse for narrow web and label production, benefits immensely. Flexo inks need to cure quickly and effectively. LED UV curing provides instant polymerization of these inks. This rapid curing process locks pigments and binders into a tough, scratch-resistant layer. The result is a print that resists scuffing and abrasion, which is vital for products handled frequently. This increased resistance translates directly to higher customer satisfaction and fewer product returns due to print damage.

Offset printing, often used for higher quality graphics and broader applications, also sees a significant boost. In offset, precise ink laydown is critical. LED curing ensures that the ink film is uniformly hardened across the entire printed surface. This uniformity prevents smudging and improves resistance to chemicals and solvents. For applications like product packaging or point-of-sale materials, this level of resistance is not just a feature; it’s a necessity. The fast cure speed also allows for immediate handling and finishing processes, streamlining production.

Narrow web printing, which encompasses labels and flexible packaging, demands efficiency and quality. LED UV systems are inherently energy-efficient. They also provide a highly consistent cure. This consistency is key to achieving reproducible print quality and ensuring every print meets durability standards. The localized heat generation of LED lamps also minimizes substrate distortion, a common concern with heat-curing methods. This is particularly important for thin films and sensitive label stocks.

The science behind LED UV curing’s enhanced durability lies in its specific wavelength output. LED lamps emit a precise spectrum of UV light. This targeted energy efficiently initiates the photoinitiators within UV-curable inks and coatings. The result is a highly efficient polymerization process. This creates a dense, tightly cross-linked polymer network. This network is inherently stronger and more resistant to physical and chemical attack than inks cured by older, broader-spectrum methods.

Consider the wear and tear a label on a beverage bottle might experience. It’s constantly handled, sometimes exposed to condensation, and might even be scrubbed. A print cured with LED technology forms a much harder surface. This surface resists scratching, rubbing, and the effects of moisture far better than conventionally cured inks. The ink doesn’t easily peel or lift. This means the visual appeal and crucial product information remain legible throughout the product’s life.

In flexo printing, especially for packaging, inks often need to withstand folding, creasing, and potential contact with product contents. LED curing creates an ink film with excellent adhesion to a wide range of substrates, from paper and film to foil. This strong adhesion prevents delamination, even under stress. The flexibility of the cured ink film is also improved, allowing it to bend with the substrate without cracking. This is a critical factor for packaging that undergoes significant manipulation.

For offset printers, the improved resistance to chemicals is a major advantage. Many printed materials, like product labels or book covers, can come into contact with oils, grease, cleaning agents, or even food products. LED-cured inks and coatings exhibit superior resistance to these substances. This prevents fading, discoloration, or degradation of the print, ensuring the integrity of the printed message and aesthetic.

The narrow web sector, with its focus on speed and precision, finds LED curing systems to be a perfect fit. The instantaneous nature of LED curing means inks are dry and fully cured as soon as they pass under the lamp. This allows for immediate post-processing, such as slitting, rewinding, or die-cutting, without the risk of smearing or offsetting. This dramatically increases throughput and reduces bottlenecks in the production line. Furthermore, the precise control over UV output means less wasted energy and a more sustainable printing process.

The long lifespan and low maintenance of LED lamps also contribute to overall operational efficiency. Unlike traditional mercury vapor lamps, LEDs do not require frequent replacement and produce minimal heat. This reduction in heat means less stress on the printing substrates, opening up possibilities for printing on more sensitive materials. The consistent energy output of LEDs also ensures a reliable and repeatable curing process, day after day.

In summary, the integration of LED UV curing systems into label, flexographic, offset, and narrow web printing processes offers tangible benefits. It directly translates to enhanced print durability and a significant increase in resistance to wear. This leads to higher quality finished products, improved operational efficiency, and a more sustainable printing workflow. The robust and resilient print surfaces achieved with LED technology are setting a new benchmark for performance in the graphic arts industry.