The printing industry is constantly evolving. Efficiency, quality, and sustainability are key drivers of progress. Modern printing presses demand solutions that meet these challenges. LED curing systems are emerging as a powerful answer. They offer a sustainable and effective way to enhance printing operations.

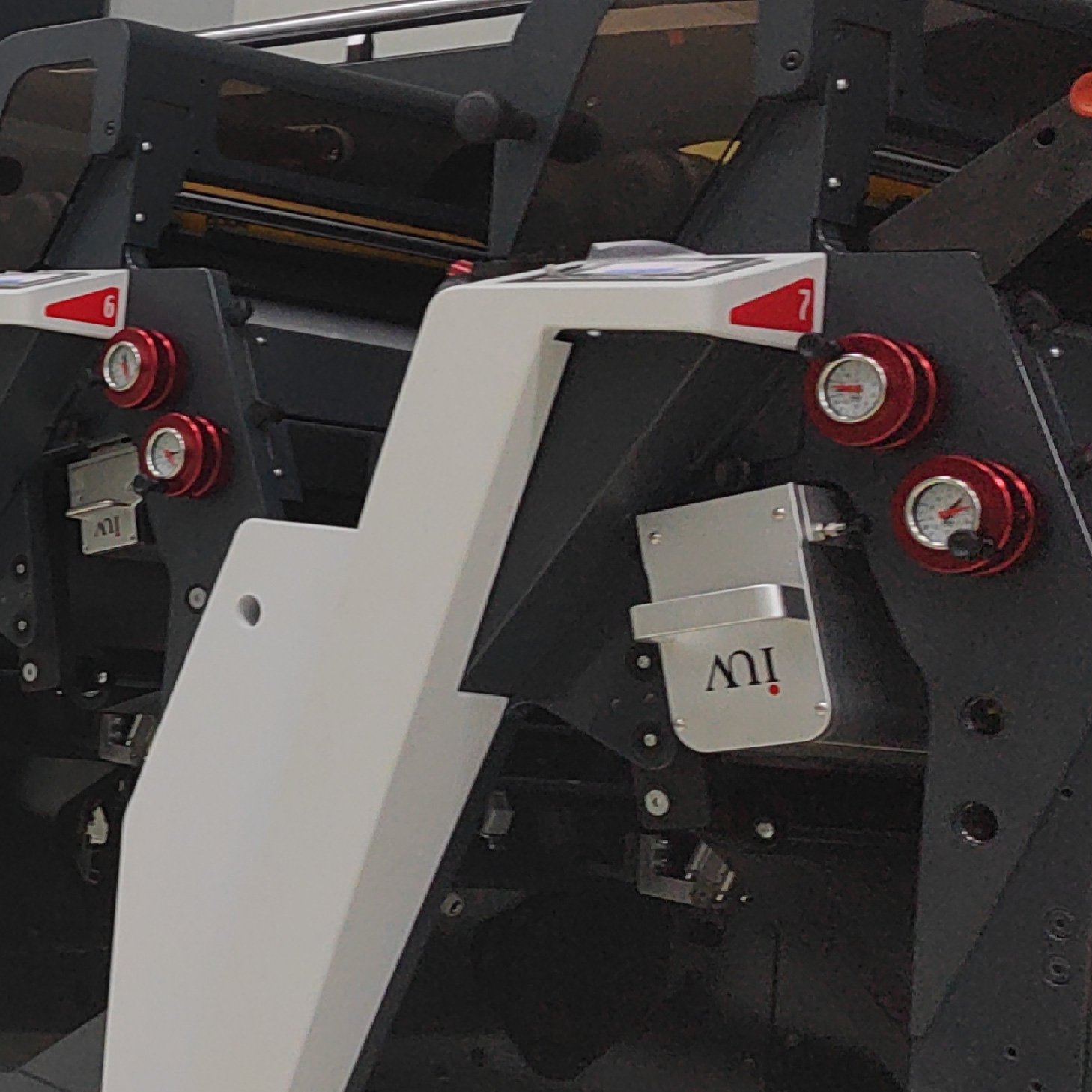

These advanced systems are transforming various printing sectors. From vibrant labels to high-volume packaging, LED UV curing is making its mark. It’s a technology that brings significant benefits to narrow web, flexographic, and offset printing presses.

The Rise of LED UV Curing in Narrow Web Printing

Narrow web printing is a specialized field. It focuses on producing labels and flexible packaging. Here, precision and speed are paramount. Traditional UV curing methods often involve mercury lamps. These lamps have drawbacks. They consume considerable energy. They also generate a lot of heat. This heat can affect sensitive substrates. Mercury lamps also contain hazardous materials. Their disposal requires careful handling.

LED UV curing systems present a compelling alternative. They use light-emitting diodes. These diodes emit UV light at specific wavelengths. This targeted emission provides efficient curing. It does so with significantly less energy consumption. The heat output is also much lower. This makes LED curing ideal for heat-sensitive materials. Think of thin films and delicate label stocks.

The advantages extend to press uptime. LED systems reach full power instantly. There is no warm-up or cool-down period. This means faster job changes and less waste. For narrow web printers, this translates directly to increased productivity. The longevity of LED lamps is another major plus. They can last tens of thousands of hours. This drastically reduces maintenance and replacement costs.

Revolutionizing Flexographic Printing with LED Technology

Flexographic printing is a workhorse in the packaging industry. It is known for its versatility and cost-effectiveness. Applying a consistent, high-quality ink layer is critical. Achieving rapid ink drying or curing is essential for smooth production flow. Historically, UV curing in flexo relied on traditional lamps.

LED UV curing is changing the game for flexo. The precise control over UV output ensures excellent ink adhesion. It also provides superior print quality. Colors appear brighter and more vivid. Rub resistance is significantly improved. This is vital for packaging that needs to withstand handling.

The lower heat output from LED systems is a boon for flexo. It allows printers to run at higher speeds. This is without risking substrate distortion or ink dot gain. The instant on/off capability also benefits short runs. It eliminates the waiting time associated with older technologies. This adaptability makes flexo more competitive. It allows for faster turnaround times. This is a critical factor in today’s market.

Enhancing Offset Printing with Sustainable UV Curing

Offset printing is renowned for its high print quality. It is often used for commercial printing, publications, and high-end packaging. While offset has traditionally used heatset or conventional drying, UV curing offers distinct advantages. Traditional UV lamps in offset presses also faced energy and heat challenges.

LED UV curing systems bring a new level of efficiency and sustainability to offset. They enable instant curing of inks and coatings. This eliminates the need for extensive drying tunnels. This saves valuable press space. It also reduces energy costs. The consistent UV output ensures uniform curing across the entire print sheet. This leads to superior gloss and matte finishes. It also improves resistance to chemicals and abrasion.

The environmental benefits are substantial. Reduced energy consumption directly lowers a printer’s carbon footprint. The absence of mercury in LED lamps also contributes to greener operations. For offset printers looking to modernize, LED curing is a smart investment. It enhances print quality and operational efficiency. It also aligns with growing demands for sustainable printing practices.

The Environmental and Economic Imperative

Sustainability is no longer an option; it’s a necessity. LED UV curing systems are a cornerstone of sustainable printing. Their energy efficiency is remarkable. They use up to 70% less energy than traditional mercury UV lamps. This translates into significant cost savings on electricity bills.

The extended lifespan of LED lamps reduces waste. Fewer lamps mean less material to dispose of. This also lowers the frequency of replacement, cutting down on operational costs and labor. The absence of mercury is a crucial environmental advantage. It eliminates the risks associated with hazardous waste disposal. This simplifies compliance with environmental regulations.

From an economic standpoint, the benefits are clear. Reduced energy consumption lowers operating expenses. Increased productivity due to faster curing and instant on/off capabilities boosts output. Lower maintenance and replacement costs contribute to a healthier bottom line. The ability to print on a wider range of substrates, including heat-sensitive ones, opens up new market opportunities.

Future-Proofing Your Printing Press

Adopting LED UV curing technology is an investment in the future. It positions printing businesses to meet the evolving demands of their clients. Brands are increasingly prioritizing sustainability. They are also seeking higher quality and faster turnaround times. LED curing directly addresses these needs.

The integration of LED systems is becoming more seamless. Manufacturers offer a variety of configurations. These can be retrofitted to existing presses or specified for new installations. This flexibility ensures that printers of all sizes can benefit.

As the technology matures, its capabilities continue to expand. New ink and coating formulations are being developed specifically for LED curing. This further enhances the potential for innovative print applications. For printers looking to stay competitive and responsible, embracing LED UV curing is a clear path forward. It’s a sustainable solution for modern printing presses, driving efficiency, quality, and environmental responsibility.