For flexo printers, the choice of UV curing technology can significantly impact print quality, efficiency, and even the bottom line. Traditionally, mercury-vapor lamps have been the workhorses in UV curing. They’ve served the industry well for a long time, offering a broad spectrum of UV light that effectively cures inks and coatings. These lamps generate heat, which can be a consideration in managing the press environment and substrate temperatures. The upfront cost of mercury lamp systems is often lower, which can be appealing for some operations.

However, the landscape is shifting, and LED UV curing systems are rapidly gaining traction, especially in narrow-web flexo printing. LED stands for Light Emitting Diode. These are semiconductor devices that emit light when an electric current passes through them. In the context of UV curing, LEDs are designed to emit specific wavelengths of UV light, typically in the UVA range (365 nm, 395 nm, etc.).

So, what are the key differences and benefits for flexo printers when comparing LED UV to traditional mercury UV?

One of the most significant advantages of LED curing is energy efficiency. LEDs consume considerably less power than mercury lamps. This translates directly into lower electricity bills, a tangible benefit for any printing operation. Think about the hours a press runs daily; those energy savings add up quickly.

Another major point is the lifespan of the lamps. Traditional mercury lamps have a finite lifespan and their UV output degrades over time. They need to be replaced periodically, and their performance can fluctuate, requiring adjustments to maintain consistent curing. LED lamps, on the other hand, have an exceptionally long operational life, often tens of thousands of hours. This means fewer replacements, less downtime for maintenance, and a more stable, predictable UV output throughout their life.

Temperature management is also a critical differentiator. Mercury lamps generate a substantial amount of heat, which can affect temperature-sensitive substrates like certain films or thin papers. This heat can lead to substrate distortion, ink smearing, or even compromise the adhesion of inks and coatings. LED systems, by contrast, emit very little heat. This “cold cure” capability opens up possibilities for printing on a wider range of delicate materials without the risk of thermal damage. This is particularly valuable in label printing, where diverse substrates are common.

When it comes to print quality, both systems can produce excellent results. However, the focused spectrum of LED UV light can offer advantages. Because LEDs emit light at very specific wavelengths, they can be precisely matched to the absorption characteristics of UV-curable inks and coatings. This targeted curing can lead to more complete and consistent polymerization of the ink film, resulting in superior scratch resistance, chemical resistance, and overall durability. This is crucial for labels that need to withstand harsh environments or frequent handling.

The instantaneous on/off capability of LEDs is another practical advantage. Unlike mercury lamps that require a warm-up period and cool-down, LEDs can be switched on and off immediately. This is beneficial for short print runs or when a press needs to be stopped and started frequently. It also means you’re not constantly running the UV lamps when the press is idle, further contributing to energy savings.

From an environmental perspective, LEDs are also a more attractive option. They don’t contain mercury, which is a hazardous substance. This simplifies disposal and makes the printing process more environmentally friendly.

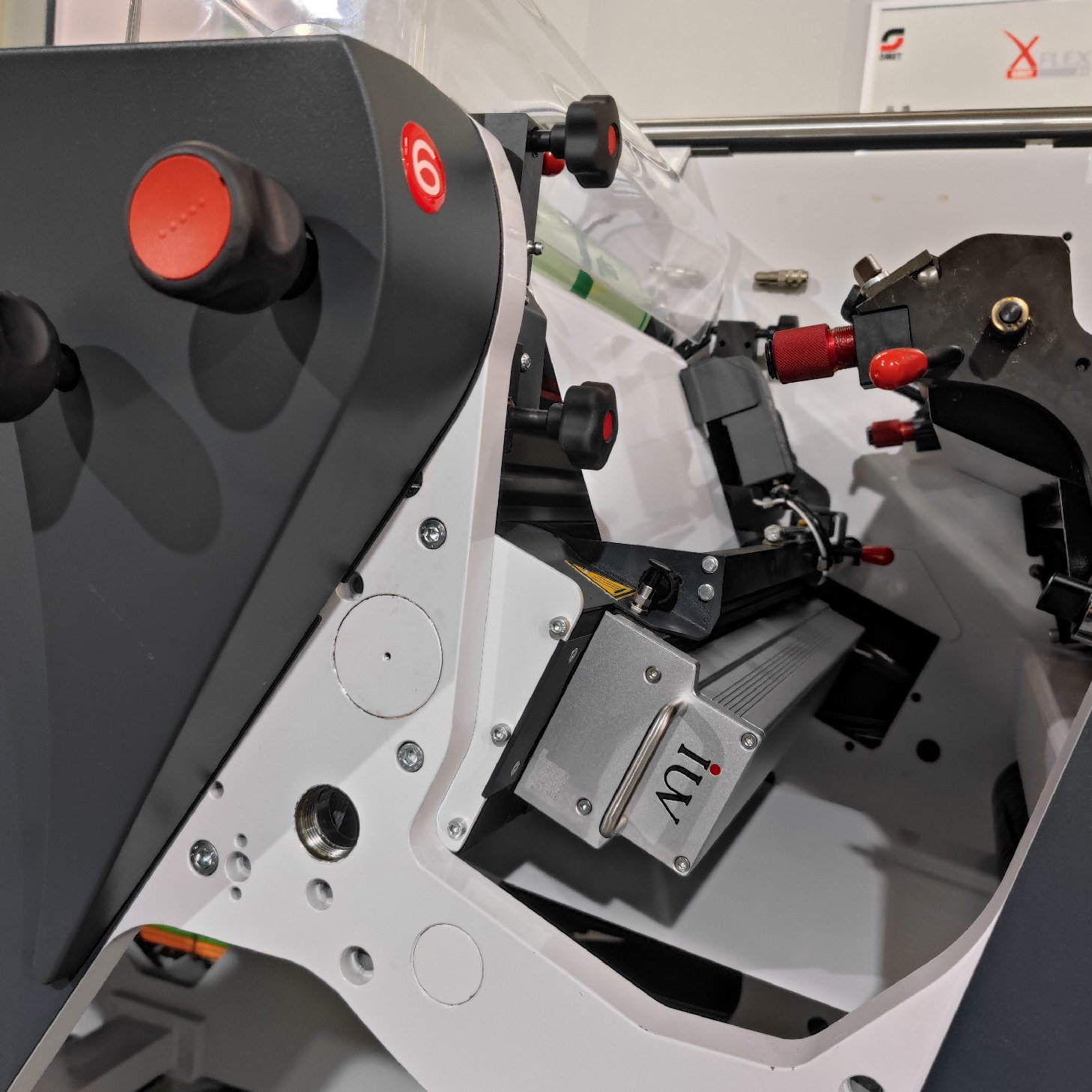

For narrow-web flexo printers, the compact nature of LED curing systems can also be a plus. They often have a lower profile, which can be advantageous in presses with limited space. Their simpler design can also mean less maintenance overall.

However, it’s important to consider the initial investment. LED UV curing systems can have a higher upfront cost compared to traditional mercury lamp systems. While the long-term savings in energy, lamp replacement, and reduced downtime are significant, the initial capital outlay can be a hurdle for some businesses. Additionally, not all UV-curable inks and coatings are formulated to perform optimally with specific LED wavelengths. It’s essential to work with ink manufacturers to ensure compatibility for the best results.

In summary, for flexo printers looking to enhance efficiency, improve print quality, expand substrate capabilities, and reduce operational costs, LED UV curing systems present a compelling case. While traditional mercury UV systems have been a reliable standard, the advancements in LED technology offer a modern, efficient, and often superior solution for the demanding world of label and narrow-web printing. The transition to LED UV is not just about adopting new technology; it’s about investing in a more sustainable, cost-effective, and high-performance future for your printing operations.