The printing industry is always evolving. New technologies emerge to improve efficiency and quality. One of the most significant recent advancements is in LED curing systems. These systems are transforming narrow web printing applications. They offer benefits across various printing methods.

Narrow web printing is a specialized field. It focuses on printing on flexible materials. These include labels, tapes, and flexible packaging. The “narrow” refers to the width of the printing substrate, typically under 300mm. This market demands high productivity and consistent quality. Traditional UV curing methods have been around for a while. They use mercury vapor lamps. While effective, these lamps have drawbacks. They consume a lot of energy. They also generate considerable heat. This heat can stress sensitive substrates. Lamp replacement is frequent and costly.

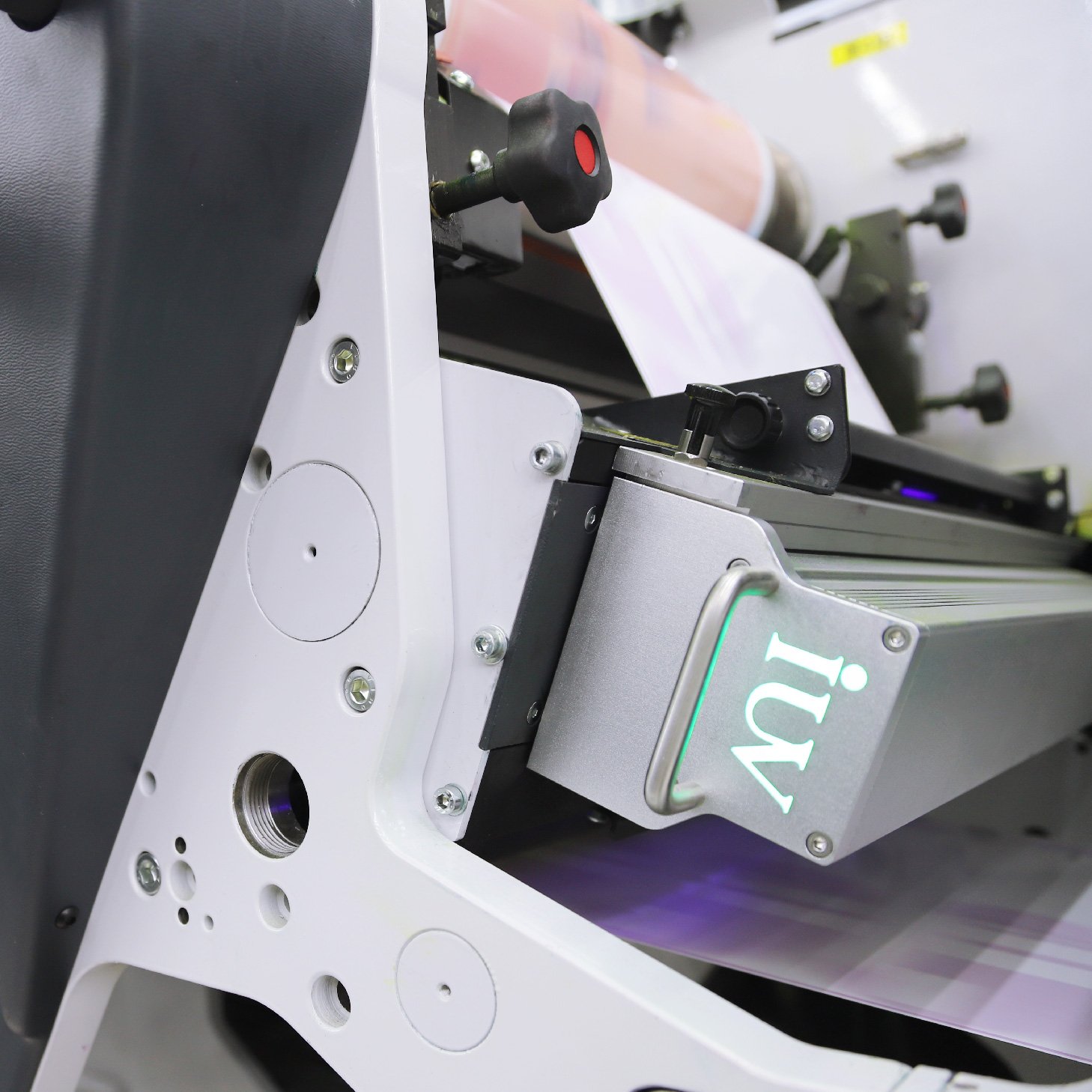

Enter LED UV curing. Light Emitting Diodes (LEDs) offer a different approach. They emit UV light at specific wavelengths. This precise control is a major advantage. LED curing systems are more energy-efficient. They consume significantly less power than mercury lamps. They also produce very little heat. This makes them ideal for heat-sensitive materials. Think of thin films or certain types of paper. The longevity of LED lamps is another key benefit. They can last much longer than traditional lamps. This reduces downtime and maintenance costs.

The evolution of LED curing systems in narrow web printing has been rapid. Early LED systems were less powerful. They couldn’t always achieve full cure on certain inks and coatings. However, technological advancements have addressed these limitations. Modern LED systems offer higher power output. They also provide a wider range of wavelengths. This allows for optimal curing of different ink formulations. This includes conventional UV inks, water-based UV inks, and LED-specific inks.

Flexographic printing is a dominant force in narrow web. It uses flexible relief plates. Flexo is known for its speed and versatility. It’s widely used for label and packaging production. Integrating LED curing into flexo presses has been a game-changer. It allows printers to achieve faster line speeds. They can also achieve excellent print quality. The instant curing of ink means less trapping. This leads to sharper images and text. It also enables inline finishing processes. Printers can apply coatings or laminates immediately after printing. This streamlines the entire production workflow.

Offset lithography, also known as sheetfed or web offset, also benefits. While traditionally associated with broader formats, offset printing on narrow web presses is common for certain applications. Offset printing relies on a chemical difference between image and non-image areas. When adapted for narrow web, the need for rapid ink setting is paramount. LED UV curing in offset narrow web applications provides this. It ensures inks cure instantly. This prevents smudging and back-trapping. It also allows for immediate handling and further processing. The reduced heat output is beneficial here too. It helps maintain substrate integrity during high-speed runs.

Inkjet printing is another area seeing significant impact. Narrow web inkjet presses are increasingly popular. They offer short-run capabilities and variable data printing. LED UV curing is almost standard in modern inkjet systems. The precise droplet placement in inkjet requires instant ink solidification. LED curing achieves this effectively. It allows for vibrant colors and durable prints on a wide range of substrates. The energy efficiency of LEDs also contributes to the overall sustainability of inkjet printing.

The benefits extend beyond just the printing process. LED curing systems contribute to a safer working environment. They do not emit ozone. Mercury lamps, in contrast, do. This means less need for extensive ventilation systems. Reduced energy consumption also translates to lower carbon footprints. This aligns with growing demands for sustainable printing practices.

Choosing the right LED curing system is important. Several factors come into play. The wavelength of the UV light is critical. Different inks are formulated to cure at specific wavelengths. Common wavelengths for LED curing include 365nm, 395nm, and 405nm. The power density of the LED array is also important. Higher power density ensures faster and more complete curing. The size and configuration of the LED unit must match the press. Cooling systems are also integrated. They ensure the LEDs operate at optimal temperatures.

The initial investment in LED curing technology can be higher. However, the long-term operational savings are substantial. Reduced energy bills, lower consumable costs for lamps, and increased productivity all contribute to a strong return on investment. As LED technology continues to advance, its capabilities will only expand further. We can expect even greater efficiency and performance in the future.

The integration of LED curing systems is a testament to innovation in the printing sector. It addresses the core needs of narrow web printing: speed, quality, efficiency, and sustainability. Whether in flexography, offset, or inkjet, LED curing is setting new standards. It empowers printers to meet the ever-changing demands of their clients. This evolution is not just about a new light source. It’s about a fundamental improvement in how we print labels and other narrow web products. The future of narrow web printing is undeniably illuminated by LED technology.