High-speed printing demands excellence. Achieving sharp, vibrant, and durable labels at rapid speeds presents a unique challenge. Traditional drying methods often struggle to keep pace, leading to ink smudging, poor adhesion, and compromised visual appeal. This is where advanced UV curing systems truly shine, offering a transformative solution for the demanding world of narrow web printing.

In label printing, especially on flexographic and offset presses, speed is paramount. The goal is to produce high volumes of labels efficiently and cost-effectively. However, faster press speeds can sometimes outrun the capabilities of conventional drying technologies. Heat-set dryers, for instance, can be slow to cool and may even cause substrate distortion, impacting the final print quality. This is where the rapid and efficient nature of UV curing becomes a game-changer.

UV curing systems utilize ultraviolet light to instantly polymerize ink, coatings, or adhesives. Unlike heat-set methods that rely on evaporation, UV curing is a photochemical process. The UV energy initiates a rapid reaction, transforming the liquid ink into a solid, dry film in fractions of a second. This instant drying capability is crucial for maintaining high printing speeds without sacrificing quality.

For narrow web presses, which are commonly used for label and flexible packaging production, the integration of UV curing offers several significant advantages in terms of print quality. One of the most noticeable improvements is in dot definition and sharpness. With conventional drying, there’s a risk of ink “wicking” or spreading as it dries, leading to softened edges and reduced detail. UV-cured inks, however, solidify almost instantaneously, locking down the ink precisely where it was applied. This results in crisper lines, finer text, and more vibrant, true-to-color images.

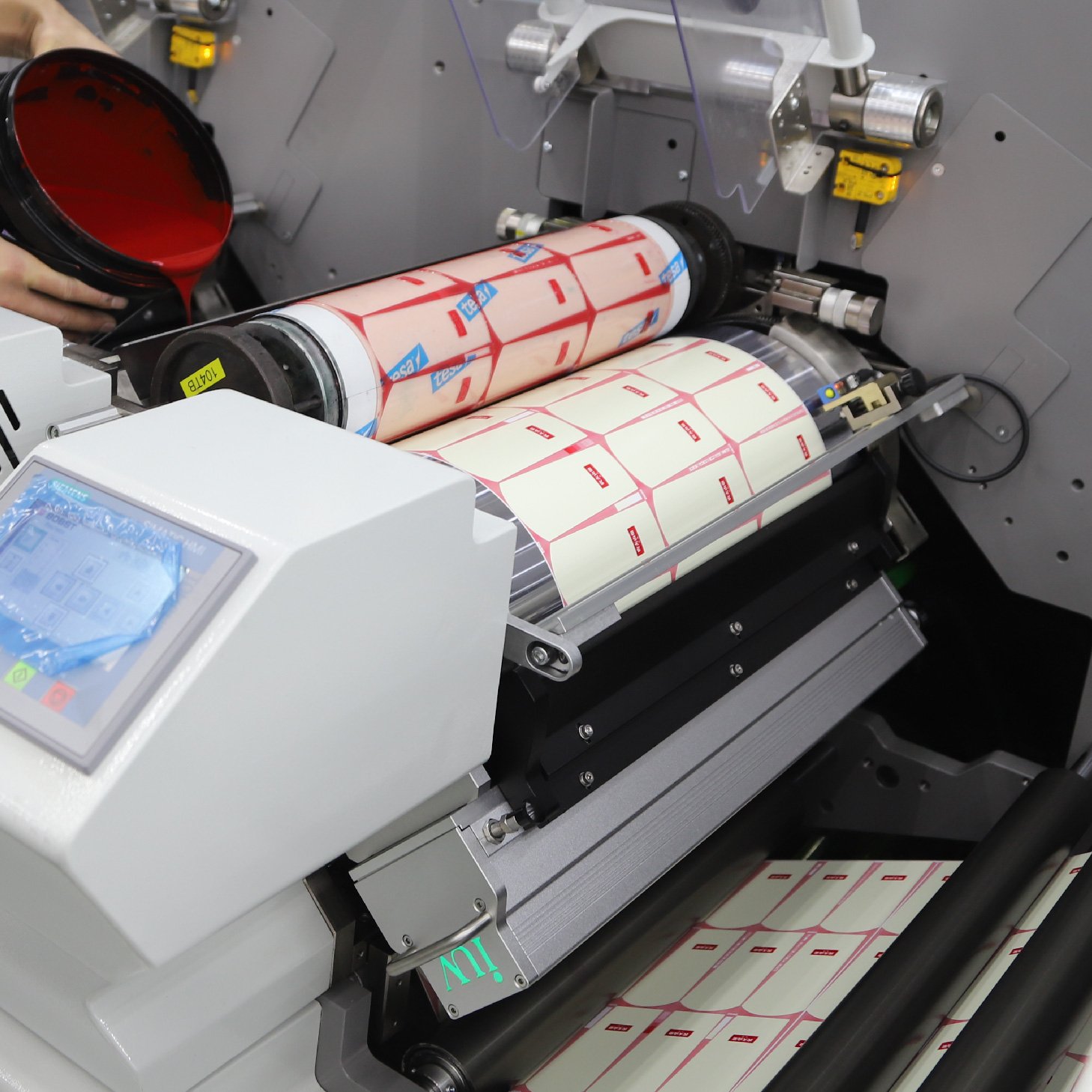

Flexographic printing, a staple in the label industry, benefits immensely from UV curing. Flexo inks, often water-based or solvent-based, can present drying challenges at high speeds. UV-curable flexo inks eliminate these issues. They offer excellent ink transfer, allowing for consistent ink laydown across the substrate. The instant cure prevents ink set-off, meaning printed sheets or webs can be immediately stacked or rewound without smearing. This drastically reduces waste and increases throughput. Furthermore, UV-curable flexo inks often provide superior rub resistance and chemical resistance, enhancing the durability and longevity of the printed labels, which is critical for many end-use applications.

Offset printing, also utilized in narrow web applications, sees similar quality enhancements with UV curing. Traditional offset inks rely on oxidation and absorption for drying, a process that can be slow and can lead to ink misting or set-off at higher speeds. UV offset inks, when cured with UV lamps, provide immediate drying. This means that multiple passes through the press for different colors can be completed without inks interfering with each other. The result is sharper imagery, cleaner solids, and the ability to achieve very fine details, even when running at high speeds. The immediate drying also allows for the use of a wider range of substrates, including non-porous materials like films and foils, which are common in the label market.

The shift towards LED UV curing technology represents another significant leap forward in improving print quality for high-speed operations. Traditional mercury vapor UV lamps generate a broad spectrum of UV light and significant heat. This heat can be detrimental to sensitive substrates, leading to shrinkage or deformation, and can also cause premature drying of the ink in the printing units, leading to issues like clogging. LED UV lamps, on the other hand, emit a much narrower spectrum of UV light at specific wavelengths, and they produce very little heat.

This “pinpoint” curing allows for more precise control over the polymerization process. The reduced heat output means that even heat-sensitive materials like thin films can be printed at high speeds without adverse effects on their dimensional stability. This expands the range of printable materials, opening up new opportunities for label converters. Furthermore, the focused UV output of LEDs often results in a more complete and thorough cure, leading to enhanced ink adhesion, improved scratch and abrasion resistance, and greater chemical resistance. This translates directly into higher quality, more durable labels that can withstand demanding environmental conditions and handling.

The immediate drying provided by UV curing systems, particularly LED UV, also contributes to better color consistency. With conventional drying, variations in drying speed or ambient temperature can affect ink density and vibrancy. UV curing ensures a consistent ink film thickness and density because the ink is locked in place instantly. This allows for more predictable and repeatable color reproduction across long print runs, which is essential for brand integrity and customer satisfaction.

In summary, for high-speed narrow web printing operations, whether using flexography or offset, UV curing systems are no longer a luxury but a necessity for achieving superior print quality. They enable faster production speeds, deliver sharper and more vibrant graphics, enhance ink adhesion and durability, and broaden the range of printable substrates. The evolution to LED UV technology further refines these benefits, offering greater energy efficiency, longer lamp life, and even more precise control over the curing process, ultimately empowering printers to meet the ever-increasing demands for high-quality labels in today’s competitive market. The ability to achieve exceptional print results consistently, even at breakneck speeds, is a testament to the power of this advanced technology.