Alright, let’s dive into the nitty-gritty of UV curing versus traditional drying for flexo printing. This is a topic near and dear to my heart, having spent my fair share of time wrestling with ink, presses, and the elusive perfect cure. Get ready for some insights that’ll make your print jobs sing and your bottom line smile.

When we talk about flexographic printing, especially for labels and narrow web applications, the speed and quality of ink drying are paramount. It’s the difference between a smooth, consistent run and a frustrating, costly mess. For years, conventional drying methods have been the workhorse. Think heat, hot air, and sometimes even IR (infrared) lamps. These systems work by evaporating the solvent or water from the ink.

The beauty of conventional drying is its familiarity. Most printers have experience with it, and the initial setup costs can be lower. However, there are definite drawbacks. Heat drying requires significant energy consumption, leading to higher operational expenses. It can also cause issues with heat-sensitive substrates, leading to shrinking, warping, or delamination. Furthermore, the slower drying times can limit press speeds, impacting overall productivity. You also often need to manage exhaust systems to deal with the evaporated solvents, adding another layer of complexity and environmental consideration.

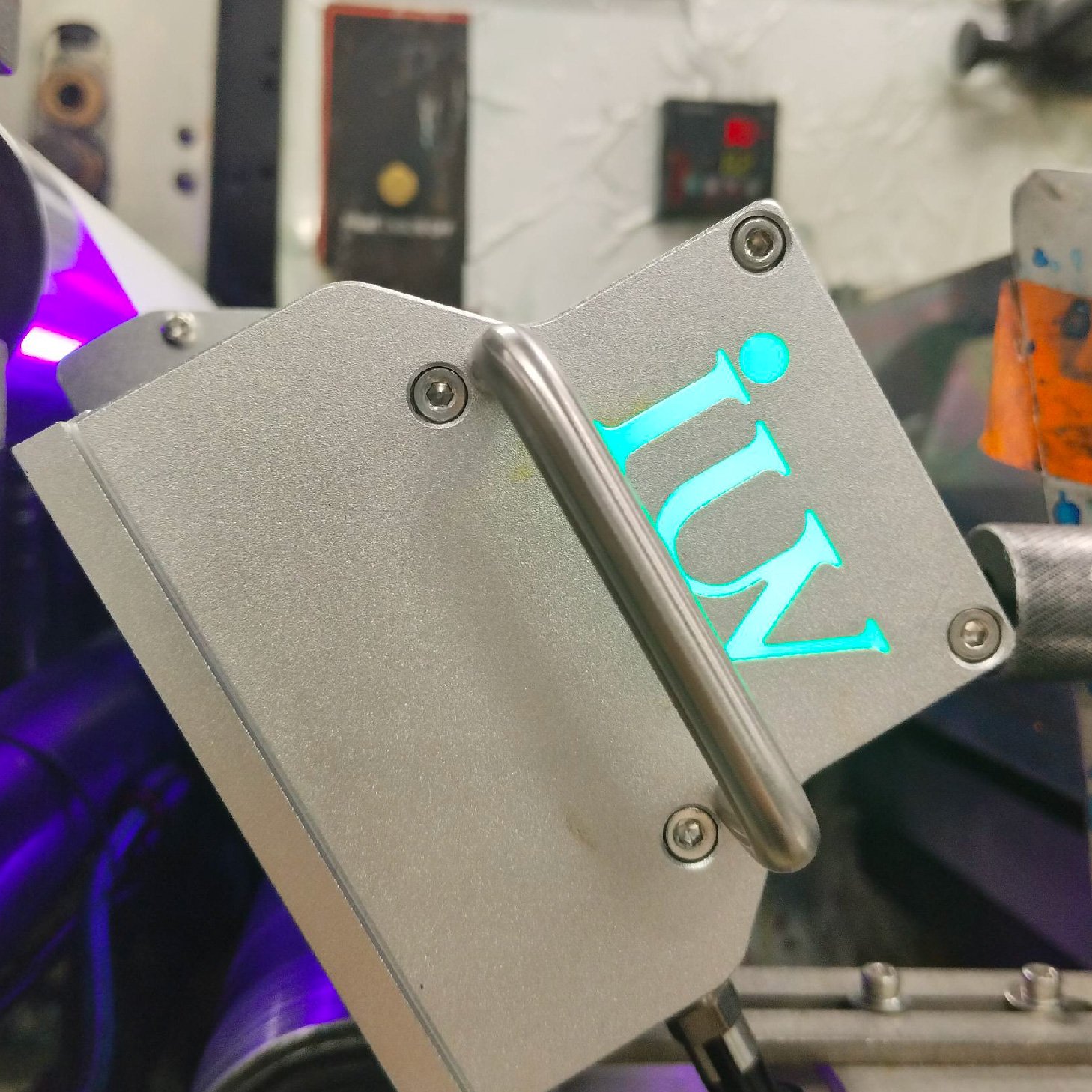

Now, let’s talk about the game-changer: UV curing systems. Specifically, LED UV curing. This technology has revolutionized the way we think about ink drying in flexo printing. Instead of evaporation, UV curing uses ultraviolet light to initiate a photochemical reaction within the ink. This reaction causes the ink to instantly polymerize, transforming from a liquid to a solid, cured film.

The difference is night and day. With UV curing, especially LED UV, the drying is virtually instantaneous. This allows for much higher press speeds, significantly boosting productivity. You can print multiple colors in close succession without worrying about ink transfer or smudging, as each layer is cured as it’s applied. This is a massive advantage in label printing where complex, multi-color designs are common.

LED UV systems offer a host of benefits over older mercury lamp UV systems and conventional drying. For starters, they are incredibly energy-efficient. They consume far less power, translating into substantial cost savings on your electricity bills. They also generate very little heat, making them ideal for delicate or heat-sensitive substrates like thin films, certain plastics, and even some papers. This versatility opens up a wider range of application possibilities.

Another significant advantage of LED UV is their long lifespan and low maintenance. Unlike mercury lamps that degrade over time and need frequent replacement, LED lamps have an operational life measured in tens of thousands of hours. They also turn on and off instantly, meaning no warm-up time is required, and you don’t need to keep them running when the press is idle. This further contributes to energy savings and reduces operational downtime.

The quality of the cured ink is another area where UV shines. UV-cured inks typically offer superior scratch resistance, chemical resistance, and color vibrancy compared to conventional inks. This is crucial for labels that need to withstand harsh environments, frequent handling, or exposure to chemicals. The cured ink film is also generally thinner and more durable.

In the realm of narrow web printing, where space is often at a premium and speed is king, LED UV curing systems integrate seamlessly. Their compact design allows for easy retrofitting onto existing presses or inclusion in new machinery. The precise control over the UV output also ensures consistent curing across the entire web width.

When comparing directly, the decision often boils down to investment versus return. While the initial cost of a UV curing system might be higher than a conventional drying setup, the long-term savings in energy, reduced waste, increased throughput, and the ability to handle a broader range of jobs often make it a more cost-effective solution over time. The improved print quality and durability also enhance the value proposition for your customers.

For label printers, especially those working with high-volume orders or demanding specifications, the transition to LED UV curing is becoming less of a luxury and more of a necessity to remain competitive. The ability to achieve vibrant colors, robust finishes, and high-speed production without compromising on substrate integrity is a powerful combination.

Consider the environmental impact as well. While conventional drying methods release VOCs (volatile organic compounds) into the atmosphere, UV curing, particularly with water-based UV inks, can offer a more eco-friendly printing process. The energy efficiency of LED UV also contributes to a reduced carbon footprint.

The technology of UV curing is constantly evolving. Newer formulations of UV inks and advanced LED curing heads are pushing the boundaries of what’s possible in flexo printing. From spot UV coatings for tactile effects to full-coverage gloss or matte finishes, the creative potential is vast.

So, to sum it up, while conventional drying has served the industry well, the benefits of LED UV curing systems in flexographic printing are compelling. Increased speeds, superior ink properties, energy savings, and substrate versatility make it a smart choice for businesses looking to enhance their print quality and operational efficiency in the competitive narrow web and label printing markets. It’s an investment that pays dividends in speed, quality, and sustainability.