Enhancing Narrow Web Printing with Advanced UV Curing Technology

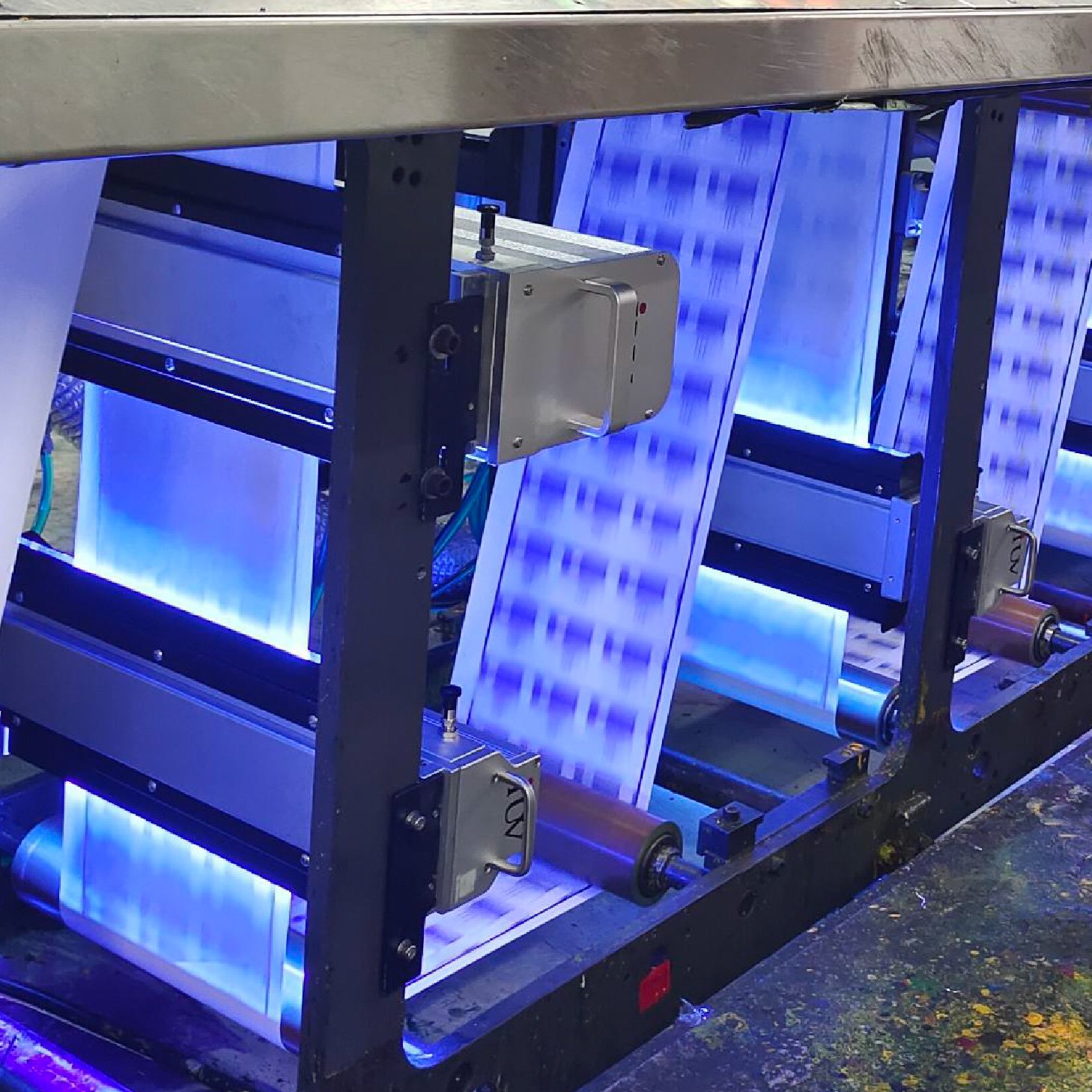

In the dynamic world of narrow web printing, efficiency, quality, and speed are paramount. Businesses constantly seek innovations to optimize their production lines and deliver superior products. One such advancement that has revolutionized the industry is the integration of UV curing systems, particularly LED UV curing technology. This powerful combination offers a wealth of benefits for label printers, flexographic operations, and even offset printing applications within the narrow web sector.

For label printing operations, the advantages are immediately apparent. UV curing provides instant drying of inks and coatings. This means finished labels can be moved immediately to the next stage of production or even finished goods packaging. There’s no waiting for inks to evaporate or set, significantly reducing production bottlenecks. This acceleration is crucial for meeting tight deadlines and fulfilling high-volume orders efficiently. Think of the time saved when rolls of perfectly cured labels can be slit, rewound, or die-cut without smudging or smearing.

Flexographic printing, a cornerstone of narrow web label production, benefits immensely from UV curing. Flexo presses often run at very high speeds. Traditional drying methods can struggle to keep up, sometimes requiring slower press speeds or more extensive drying tunnels that consume considerable energy. UV curing, however, dries inks and varnishes almost instantaneously as they pass under the UV lamps. This allows flexo presses to operate at their maximum speed capabilities. The result is higher throughput and greater productivity, directly impacting the bottom line.

Moreover, UV inks cured under UV light exhibit exceptional durability and resistance. They are resistant to abrasion, chemicals, and fading from light exposure. This is vital for labels that will be subjected to harsh environments, such as those found on food and beverage products, industrial chemicals, or automotive parts. The vibrant colors and sharp print quality are preserved, ensuring brand integrity and product appeal throughout the label’s lifecycle. The precise control offered by UV curing systems also leads to sharper dot definition and better ink laydown, crucial for intricate designs and fine text.

Offset printing, while sometimes seen as more suited to sheetfed applications, also finds a place in narrow web printing. When narrow web offset presses utilize UV curing, they achieve similar advantages. The instant drying allows for immediate handling and finishing, and the high-quality print typically associated with offset is further enhanced by the superior ink adhesion and durability provided by UV curing. This means even complex, multi-color designs can be reproduced with incredible fidelity and long-lasting appeal.

The shift towards LED UV curing technology represents a significant leap forward. Unlike traditional mercury vapor UV lamps, LED UV systems offer a host of environmental and economic advantages. They consume considerably less energy, leading to lower operating costs. They also generate less heat, which is beneficial for printing on heat-sensitive substrates like thin films or certain plastics commonly used in packaging and labels. The lifespan of LED lamps is also significantly longer than traditional lamps, reducing maintenance downtime and replacement costs.

From a process engineering standpoint, the control and consistency offered by LED UV systems are remarkable. They provide a more uniform light spectrum and intensity, ensuring consistent curing across the entire web width and throughout the print run. This consistency minimizes waste due to curing inconsistencies and ensures that every label printed meets the same high standards. The absence of ozone generation, a byproduct of mercury lamps, also contributes to a safer and more pleasant working environment for press operators.

The versatility of UV curing systems in narrow web printing cannot be overstated. They support a wide array of inks, including conventional UV, low-migration UV (essential for food packaging), and specialty effect coatings. This allows printers to offer a diverse range of finishes, from high-gloss to matte, and to incorporate unique tactile or visual effects that enhance product shelf appeal. The ability to overprint UV-cured inks with further UV coatings or varnishes opens up endless possibilities for customization and premium finishes.

For printers considering an upgrade, the investment in UV curing technology, especially LED UV, yields substantial returns. The increased press speeds, reduced waste, lower energy consumption, and enhanced product quality all contribute to improved profitability and competitiveness. Furthermore, the ability to handle a wider range of substrates and produce more durable, high-quality labels and packaging means printers can expand their service offerings and attract new business opportunities. The future of efficient, high-quality narrow web printing is undeniably linked to the intelligent application of advanced UV curing solutions. The precision, speed, and sustainability they bring are transforming what’s possible in this demanding print sector.