Understanding UV Curing Technology

UV curing uses ultraviolet light to instantly dry inks, coatings, and adhesives. This process is fundamentally different from traditional heat drying. Instead of evaporating solvents, UV curing initiates a photochemical reaction. Photoinitiators in the ink absorb UV energy and create reactive species. These species then rapidly link together, forming a solid, cured film. This process is incredibly fast, often taking mere seconds or even fractions of a second.

The benefits are substantial. Instant curing means faster press speeds. It allows for immediate handling and finishing of printed products. This drastically reduces the risk of smudging or scratching. UV inks and coatings are also known for their exceptional durability, resistance to chemicals, and vibrant color reproduction. Furthermore, UV curing systems typically consume less energy than traditional drying methods, contributing to a more sustainable printing process.

LED UV vs. Traditional Mercury Vapor Lamps

Historically, UV curing relied on mercury vapor lamps. These lamps are effective but have several drawbacks. They generate significant heat, which can be detrimental to heat-sensitive substrates. They also emit a broad spectrum of UV light, including wavelengths that are not utilized for curing, leading to energy waste. Mercury vapor lamps have a limited lifespan and require frequent replacement, adding to operational costs and posing disposal challenges due to their mercury content.

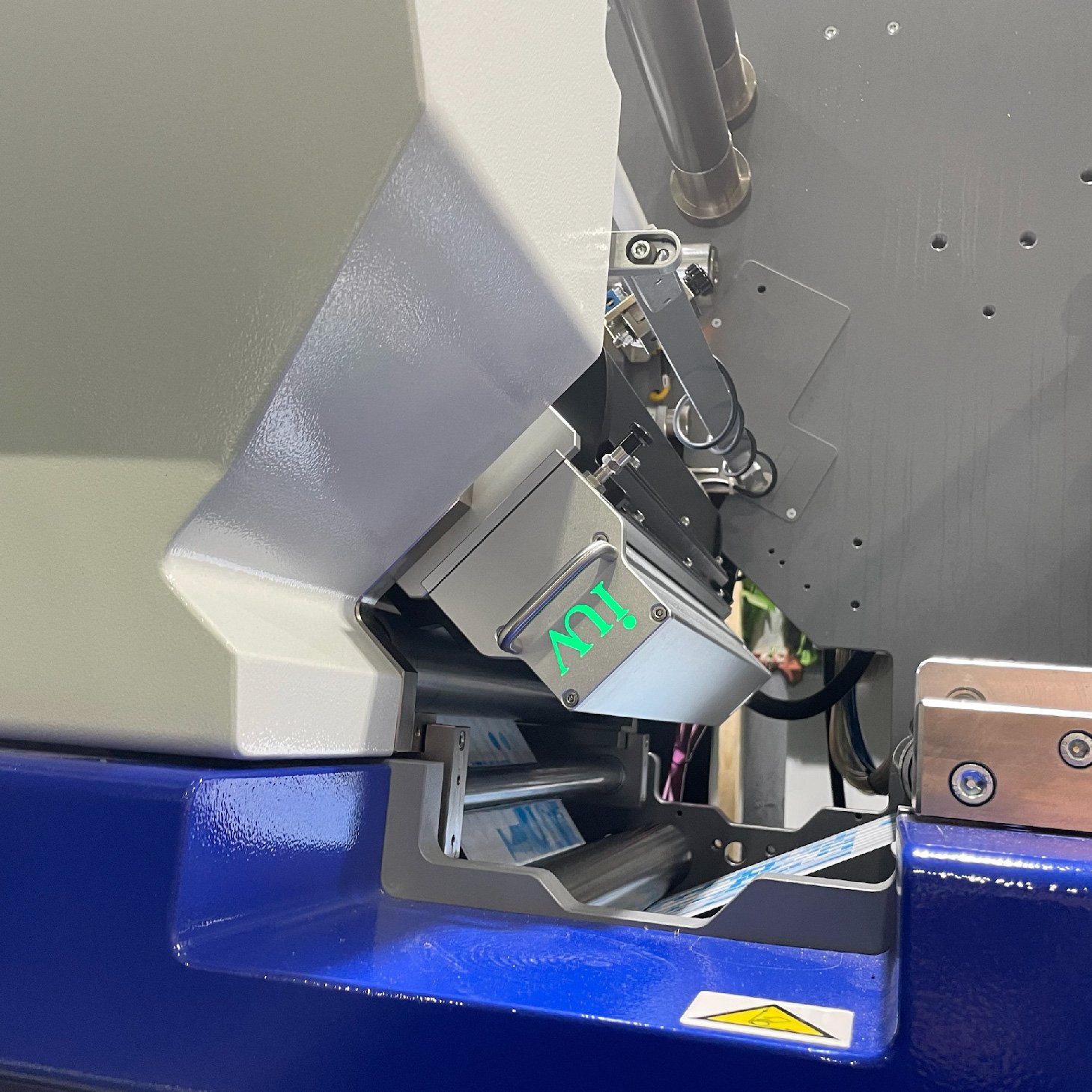

In recent years, Light Emitting Diode (LED) UV technology has emerged as a superior alternative. LED UV systems offer a highly targeted wavelength output, precisely matched to the absorption spectrum of common UV inks and coatings. This precision means less wasted energy and more efficient curing.

The advantages of LED UV are compelling:

- Lower Heat Output: LED UV lamps produce minimal heat. This opens up a wider range of printable materials, including delicate plastics and thin films, without deformation or damage.

- Energy Efficiency: LEDs are significantly more energy-efficient than mercury vapor lamps. They consume less power and can often be switched on and off instantly, further saving energy.

- Longer Lifespan: LED UV lamps have a much longer operational life, often exceeding 20,000 hours. This drastically reduces maintenance and replacement costs.

- Instant On/Off: Unlike mercury lamps that require a warm-up period, LEDs are instantly at full power. This improves workflow and reduces wasted energy during press setup or idle times.

- No Mercury: LED systems are environmentally friendly, as they do not contain mercury. This simplifies disposal and aligns with sustainability goals.

- Compact Design: LED UV curing units are often more compact, making them easier to integrate into existing printing presses.

Choosing the Right UV System for Your Printing Needs

The “right” UV curing system depends heavily on your specific printing applications and substrate choices. Let’s look at some common scenarios in narrow web printing.

1. Label Printing

For narrow web label printing, especially for high-volume production, efficiency and substrate versatility are key. Many labels are printed on films or thin papers that can be sensitive to heat.

- Consider LED UV: If you’re printing on plastics, BOPP, PE, or other heat-sensitive films, LED UV is almost certainly the best choice. Its low heat output prevents substrate distortion and maintains print integrity.

- Ink Compatibility: Ensure the LED UV system’s wavelength output matches your chosen UV inks. Most modern UV inks are formulated for LED curing.

- Curing Intensity: For opaque inks, metallic inks, or thick varnish applications, higher UV intensity (irradiance) might be needed. Discuss this with your ink supplier and equipment manufacturer.

2. Flexographic Printing

Flexography is widely used for packaging, labels, and flexible films. UV curing in flexo offers speed and durability benefits.

- Inline Curing: Most flexo presses incorporate UV curing units inline between print stations. This allows for process colors (CMYK) to be printed and cured sequentially, enabling vibrant, high-definition graphics.

- Spot UV and Varnishes: UV systems are excellent for applying spot varnishes to highlight areas or create tactile effects. Ensure your system can deliver consistent, high-quality coating.

- Substrate Range: Flexo often prints on a variety of substrates, from paper to various plastics. LED UV’s low heat is advantageous here, but traditional mercury lamps might still be considered for certain high-temperature resistant substrates if cost is a primary driver. However, the long-term benefits of LED usually outweigh the initial cost difference.

3. Offset Printing (Sheet-fed and Web)

While offset printing has traditionally used heatset or air drying, UV curing is gaining significant traction, especially in sheet-fed applications for high-end commercial printing and packaging.

- Sheet-fed Offset: For applications requiring immediate finishing, such as business cards, brochures, or packaging where gloss and scratch resistance are paramount, UV offset is ideal. LED UV systems can be retrofitted to many existing offset presses.

- Web Offset: In web offset, UV curing can significantly boost productivity by eliminating the need for long drying tunnels, allowing for faster rewind speeds.

- Ink and Coating Systems: Ensure the UV system is robust enough to handle the higher ink laydowns common in offset printing and the demands of thicker coating applications.

Key Factors to Consider When Selecting Your UV System:

- Wavelength: Confirm the UV system’s output matches your ink and coating specifications. Common LED wavelengths are 365nm, 385nm, 395nm, and 405nm. Mercury lamps cover a broader spectrum.

- Irradiance (Intensity): This is the power density of the UV light, measured in W/cm². Higher irradiance means faster curing, but it must be balanced with the ink’s ability to absorb that energy.

- Dose (Energy Density): This is the total amount of UV energy delivered, calculated as irradiance multiplied by exposure time (Joules/cm²). Both irradiance and dose are critical for full cure.

- Substrate Type: As discussed, heat sensitivity is a major factor.

- Press Speed: The UV system must be capable of curing ink adequately at your press’s maximum operating speed.

- Curing Unit Placement: Decide whether you need spot curing, full-width curing, or curing at multiple points on the press.

- Manufacturer Support and Service: Reliable technical support and readily available parts are vital for minimizing downtime.

- Budget and ROI: While LED UV systems may have a higher upfront cost, their energy savings, reduced maintenance, and increased productivity often provide a strong return on investment over time.

Investing in the right UV curing system is a strategic decision that can propel your printing business forward. By carefully considering your specific needs, understanding the technology, and evaluating the benefits of LED UV, you can make an informed choice that enhances quality, boosts efficiency, and ensures your competitive edge in the market.