The commercial printing landscape is shifting beneath our feet. Traditional methods struggle to keep pace with demands for faster turnaround, sharper detail, and greener processes. Enter LED UV offset technology – not just another incremental improvement, but a fundamental reimagining of how ink meets substrate. This innovation doesn’t simply tweak existing workflows; it rewrites the rules for label production, flexographic applications, sheet-fed operations, and narrow web printing.

Label printers face unique challenges – intricate designs on delicate materials, strict compliance requirements, and brutal production schedules. Conventional UV curing often overheats sensitive substrates, warping thin label stocks or compromising adhesive integrity. LED UV systems operate at significantly lower temperatures while achieving instant curing. This thermal precision enables razor-sharp registration on pressure-sensitive materials without the cockling effect that plagues traditional methods. Pharmaceutical labels requiring micro-text? Food packaging demanding scratch-resistant inks? LED UV handles both with equal finesse.

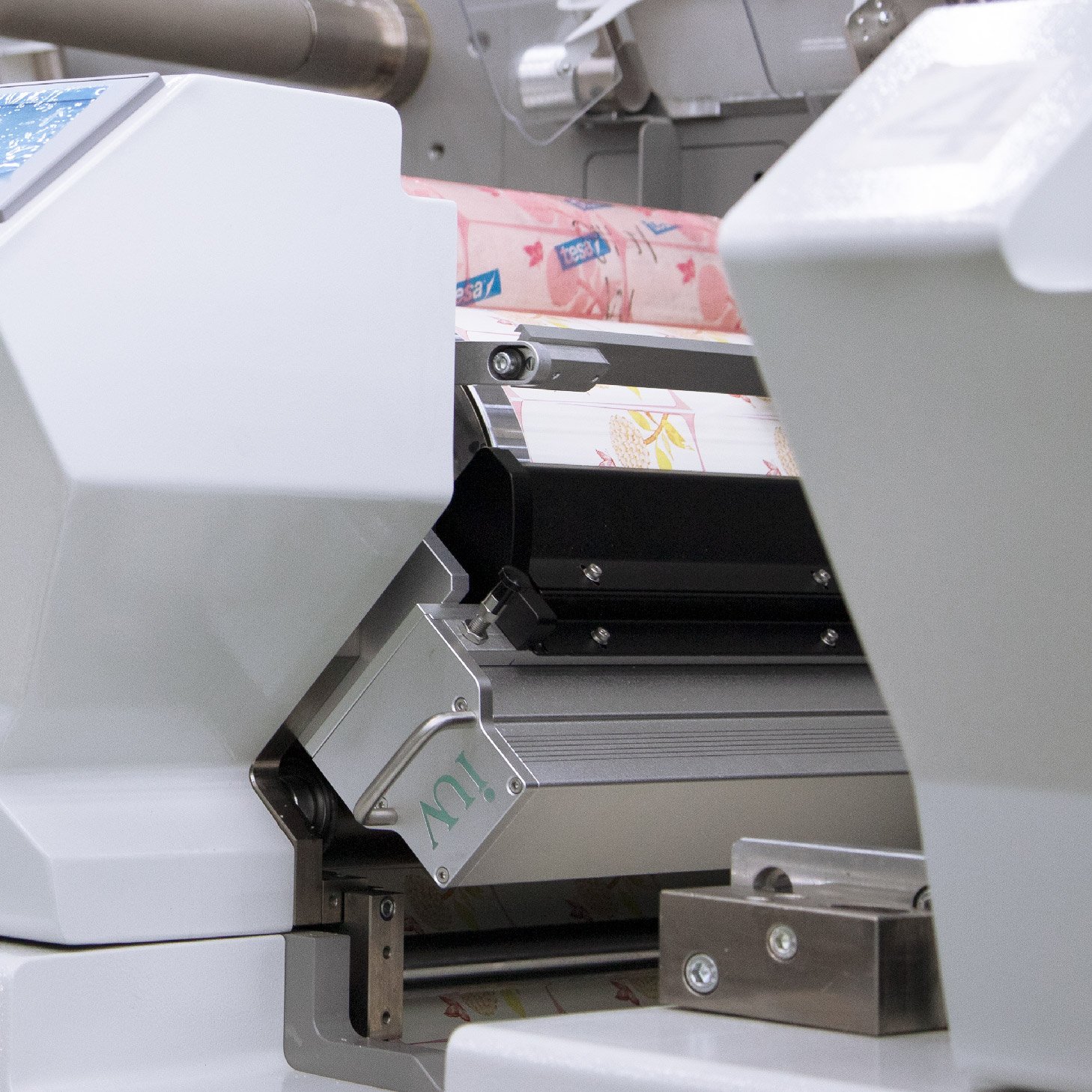

Flexographic operations, particularly in packaging, reap dramatic benefits from this technology’s spatial efficiency. The compact nature of LED arrays allows for tighter print station configurations – crucial for multi-color jobs on flexible films and shrink sleeves. Unlike mercury vapor lamps that degrade over time, LED units maintain consistent output throughout their lifespan. This stability proves critical when printing extended gamut color work on polypropylene substrates, where even minor fluctuations in curing energy can alter color perception.

Sheet-fed offset shops discover unexpected advantages when integrating LED UV. The instant cure capability transforms workflow logistics – no more waiting for sheets to dry before handling. Perfecting units become more viable with cured sheets that won’t offset when flipped. Heavy coverage jobs on coated stocks no longer risk set-off during stacking. Perhaps most crucially, LED UV enables printing on non-traditional substrates that would buckle under conventional drying systems. Think synthetic papers for outdoor applications or metallic stocks for premium packaging – all now within reach without secondary processes.

Narrow web converters operating in hybrid environments find particular synergy with LED UV systems. The technology’s compatibility with water-based coatings and specialty inks opens new hybrid printing possibilities. Imagine combining variable data digital printing with offset-quality color consistency, all cured instantly without compromising web tension. This combination proves ideal for security printing applications requiring both high-resolution graphics and precise registration across continuous rolls.

Energy consumption patterns tell a compelling story. Traditional UV systems operate like old incandescent bulbs – full power until switched off. LED arrays respond like dimmable lights, scaling energy use to substrate speed and ink coverage. This dynamic adjustment slashes power consumption by up to 70% compared to conventional UV setups. The implications extend beyond utility bills: reduced heat generation means smaller HVAC systems, lower carbon footprints, and improved worker comfort in pressrooms.

Ink chemistry undergoes quiet revolution alongside hardware advancements. LED-specific formulations achieve remarkable opacity without heavy pigment loading. This proves particularly valuable in white ink applications for metallic substrates, where coverage traditionally required multiple passes. Printers achieve brighter whites in single hits, reducing ink consumption while maintaining vibrancy. The absence of photoinitiators in some next-gen LED inks eliminates VOC concerns entirely – a game-changer for food packaging and children’s product printing.

Durability metrics rewrite client expectations. Abrasion resistance tests show LED-cured inks outperforming traditional UV counterparts by significant margins. Printed pieces withstand repeated flexing without cracking – critical for folding cartons and flexible packaging. Adhesion tests on difficult substrates like polyethylene reveal bond strengths previously attainable only through corona treatment or flame priming. This durability extends product lifespan while reducing returns from scuffed labels or degraded packaging graphics.

The operational tempo of print shops accelerates with LED UV integration. Instant curing enables inline finishing processes that previously required separate passes. Embossing, die-cutting, and foil stamping can now occur immediately after printing without risk of smearing. This compression of production steps proves particularly valuable in short-run premium packaging where changeover times traditionally ate into profitability.

As global regulations tighten on chemical usage and energy consumption, LED UV positions printers ahead of compliance curves. The technology’s mercury-free nature satisfies evolving environmental directives while future-proofing operations against anticipated bans on traditional UV systems. Early adopters report unexpected marketing benefits – sustainability-focused clients increasingly specify LED UV production in RFPs, creating new competitive differentiation opportunities.

The true disruption lies in redefining what’s printable. Temperature-sensitive materials like thin-gauge PET films and heat-transfer papers transition from problematic substrates to routine jobs. Textile applications gain traction as LED-cured inks bond to fabrics without thermal distortion. Even three-dimensional surfaces become viable targets through precise energy control during curing – imagine printing directly on molded plastic components without secondary labeling.

This isn’t merely another equipment upgrade. It’s a paradigm shift in how ink interacts with surface, how energy translates to permanence, and how printers conceptualize their craft. The fusion of precision optics with advanced photochemistry creates possibilities that ripple beyond print shops into product design labs and manufacturing floors. Those who master this convergence will define commercial printing’s next chapter – one where quality, speed, and sustainability coexist without compromise.