How UV Curing Systems Revolutionize Competitive Printing

In today’s fast-paced print industry, staying ahead means adopting technologies that boost efficiency, quality, and sustainability. UV curing systems have emerged as a game-changer for printers—especially in label, flexographic, offset, and narrow-web applications. By integrating LED UV curing technology, print businesses reduce waste, accelerate production, and meet evolving client demands. Let’s explore how this innovation keeps printers competitive.

1. Instant Curing for Label Printing Efficiency

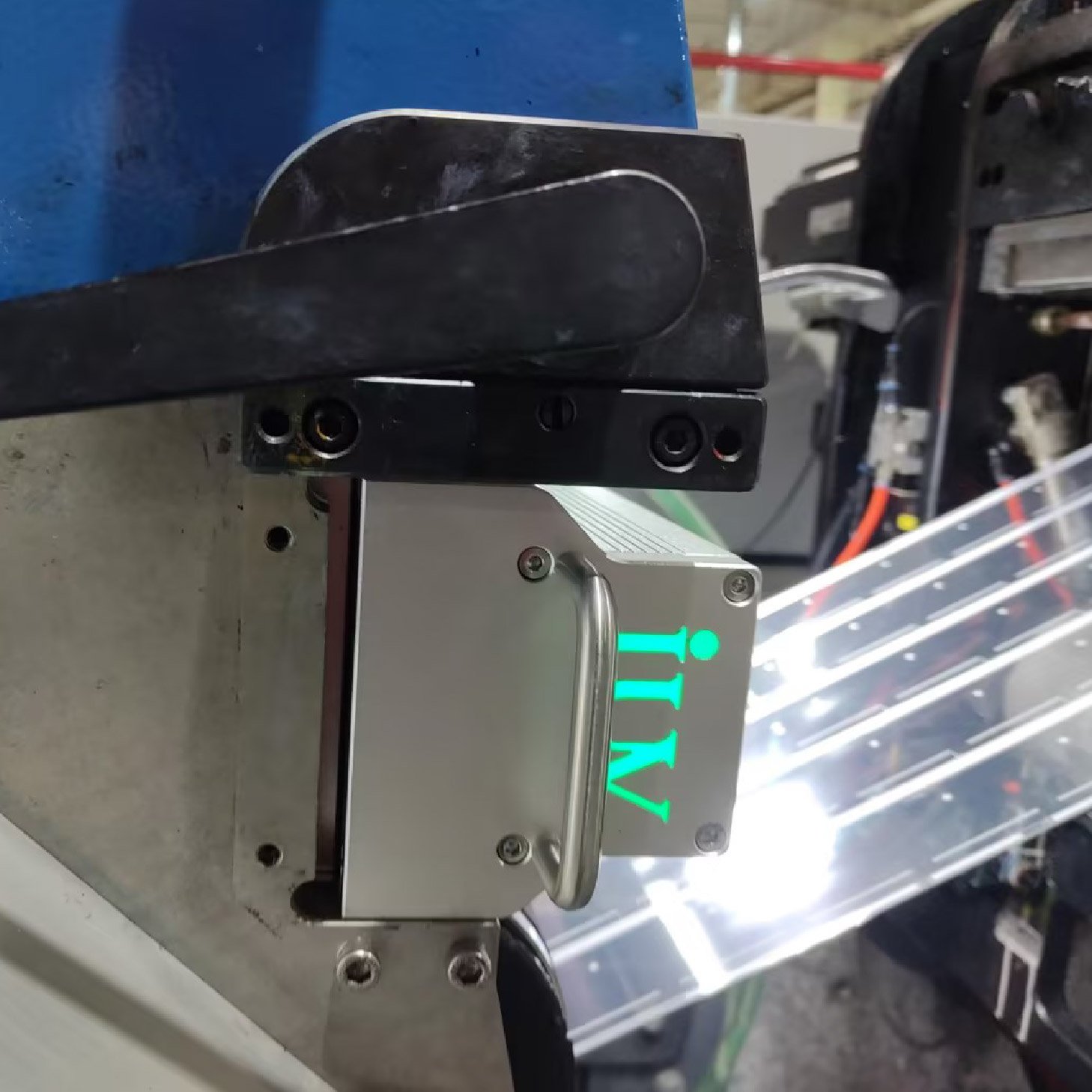

Label printers face tight deadlines and complex designs requiring vibrant colors and durable finishes. Traditional solvent-based inks dry slowly, creating bottlenecks. UV curing systems eliminate this delay by instantly hardening inks and coatings under ultraviolet light.

LED UV lamps, unlike conventional mercury-based units, emit precise wavelengths to trigger photochemical reactions in seconds. This allows label printers to:

- Reduce drying time from minutes to near-instantaneous results.

- Handle heat-sensitive substrates (e.g., thin films, synthetic labels) without warping.

- Achieve high-gloss or matte finishes that resist scratching and chemicals.

With faster turnaround times and fewer defects, label printers can take on high-volume orders while maintaining premium quality.

2. Flexographic Printing: Expanding Material Possibilities

Flexo printers specializing in packaging rely on versatility. UV curing enhances this by enabling compatibility with diverse substrates—plastic, metallic films, even non-porous materials. Unlike water-based inks, UV-curable formulations don’t penetrate surfaces, ensuring sharp graphics and consistent color on challenging materials.

Key advantages include:

- Reduced ink consumption: UV inks remain on the substrate’s surface, requiring less volume.

- Eco-friendly operations: Solvent-free inks minimize VOC emissions, aligning with sustainability goals.

- Enhanced durability: Prints withstand abrasion, moisture, and UV exposure—critical for retail packaging.

By adopting UV curing, flexo printers attract clients needing resilient, visually striking packaging for competitive markets.

3. Offset Printing: Quality Meets Speed

Offset printers balancing high-quality output with speed benefit from UV curing’s dual advantages. Traditional offset inks require extended drying periods, limiting productivity. UV systems allow immediate curing, so sheets can be cut, folded, or laminated right off the press.

For commercial printers, this means:

- Faster job completion for brochures, catalogs, and promotional materials.

- Ability to print on coated stocks without risking set-off (ink transfer).

- Brilliant color saturation and gloss levels that captivate end-users.

UV-curable offset inks also reduce energy costs. LED lamps consume up to 70% less power than mercury alternatives, lowering operational expenses.

4. Narrow-Web Printing: Agility for Custom Jobs

Narrow-web printers serving niche markets—like specialty labels, decals, or security prints—require agility. UV curing supports short runs and rapid job changes without compromising quality.

Benefits include:

- On-demand printing: Cure only what’s needed, minimizing waste.

- Hybrid printing capabilities: Combine digital, flexo, and screen printing with instant curing at each stage.

- Enhanced adhesion: UV inks bond strongly to tricky surfaces like glass, electronics, or automotive parts.

This flexibility lets narrow-web printers profit from customized, low-volume orders increasingly demanded by brands.

5. Sustainability: A Strategic Advantage

Modern clients prioritize eco-conscious partners. UV curing systems help printers meet this demand:

- Energy efficiency: LED UV lamps last longer (15,000 hours) and generate less heat, cutting cooling costs.

- Zero solvents: UV inks contain no volatile organic compounds, improving workplace safety.

- Recyclability: Prints on plastic or foil can be recycled more easily since UV inks don’t contaminate materials.

By marketing these green credentials, printers differentiate themselves in industries like food packaging or eco-branded products.

6. Cost-Effective Upgrades with ROI

Transitioning to UV curing isn’t just about technology—it’s a smart financial move. While initial investments vary, many printers see returns within 12–18 months through:

- Reduced downtime (no drying delays).

- Lower energy and consumable costs.

- Ability to charge premiums for specialty finishes or rapid services.

Modular systems allow gradual integration, making upgrades feasible for small to mid-sized shops.

Conclusion

UV curing systems empower printers to thrive in a competitive landscape. By delivering speed, versatility, and sustainability, LED UV technology addresses the core challenges of label, flexo, offset, and narrow-web printing. Printers who adopt this innovation not only future-proof their operations but also unlock new revenue streams in high-value markets.

To maintain a competitive edge, evaluate how UV curing can optimize your workflows, reduce costs, and elevate print quality. Partner with trusted suppliers to tailor solutions that align with your specific applications and business goals.