How UV Curing Systems Revolutionize Overprint Varnish Performance in Modern Printing

In the competitive world of printing, achieving flawless finishes and durable products is non-negotiable. Overprint varnishes (OPV) play a pivotal role in enhancing visual appeal and protecting printed materials. However, traditional drying methods often fall short in speed, consistency, and environmental impact. Enter UV curing systems—a game-changer for label, flexographic, offset, and narrow-web printing. Let’s explore how this technology elevates OPV performance across industries.

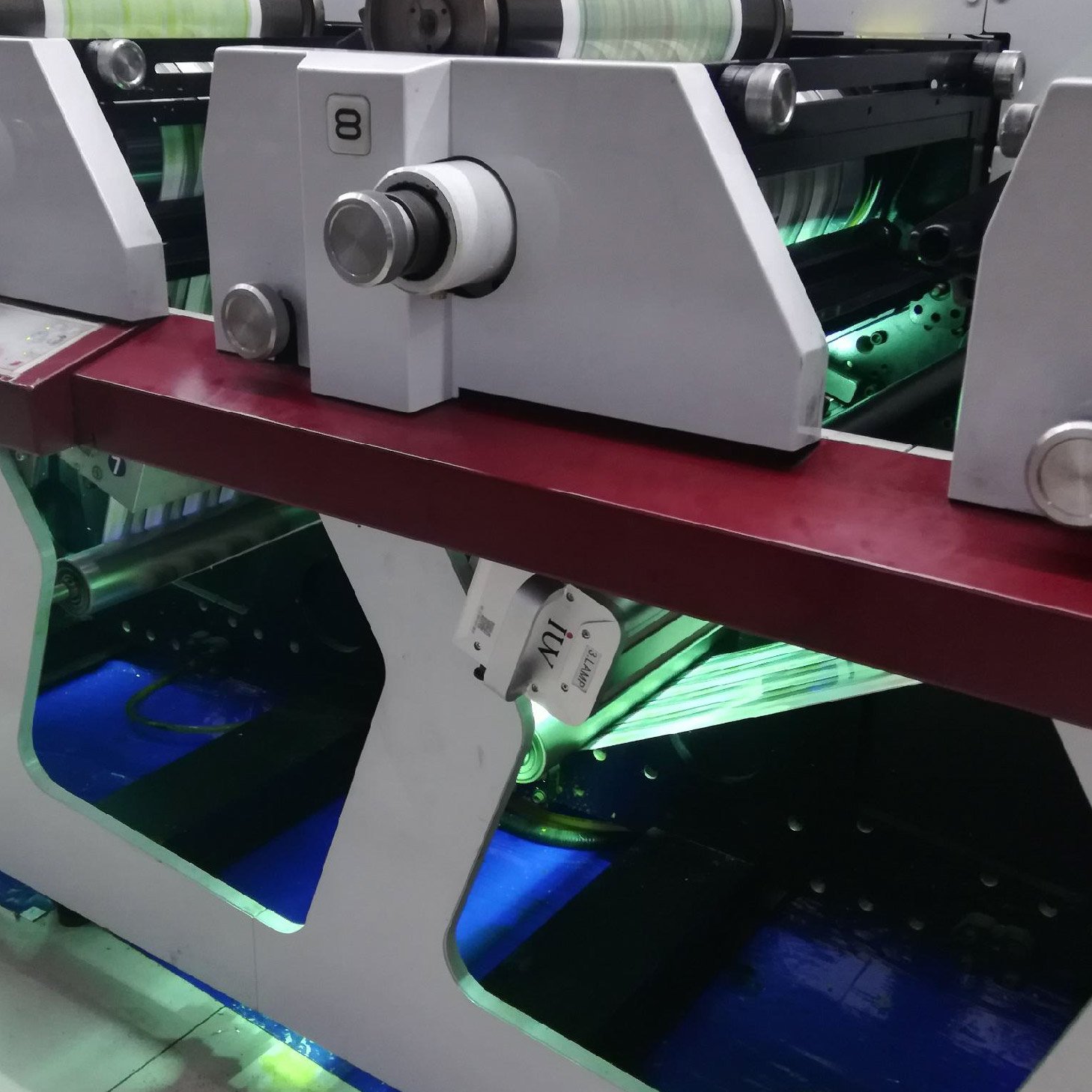

UV Curing 101: Speed Meets Precision

UV curing systems use ultraviolet light to instantly polymerize coatings, inks, and varnishes. Unlike conventional drying, which relies on evaporation, UV energy triggers a photochemical reaction in the varnish’s photoinitiators. This creates a cross-linked, hardened surface in seconds. For time-sensitive projects like label printing or short-run packaging, this rapid cure minimizes bottlenecks. LED UV systems take it further by offering mercury-free operation, reduced heat output, and energy savings of up to 70% compared to traditional UV lamps.

Enhanced Durability for Demanding Applications

Overprint varnishes cured by UV systems deliver unmatched resistance to scratches, chemicals, and abrasion. In flexographic printing—widely used for flexible packaging—UV-cured OPVs withstand friction during transportation and storage. For label printing, where products face moisture and handling, this durability ensures barcodes and graphics remain legible. Narrow-web printers benefit too: UV varnishes on shrink sleeves or cosmetic labels retain gloss even after repeated contact with oils or lotions.

Superior Finish Quality with Minimal Waste

UV curing eliminates solvent evaporation, reducing VOC emissions and ensuring consistent varnish thickness. In offset printing, this precision prevents mottling or uneven gloss on high-end brochures or magazines. The instant cure also allows for “wet-on-dry” layering—applying multiple coatings without waiting for drying. A label printer can add a matte varnish over a glossy UV-cured base, creating tactile effects that captivate consumers.

Energy Efficiency and Sustainability

LED UV systems shine in sustainability. They consume less power, generate minimal heat, and have lifespans exceeding 20,000 hours. For eco-conscious brands, this aligns with reduced carbon footprints. Additionally, UV-cured varnishes contain fewer volatile compounds, making them safer for food-grade packaging and pharmaceutical labels.

Applications Across Printing Methods

- Label Printing: UV systems enable high-speed production of waterproof, scuff-resistant labels for beverages or household chemicals.

- Flexographic Printing: Instant curing prevents ink offsetting on flexible films, critical for snack packaging.

- Offset Printing: Achieve dazzling spot varnish effects on premium product catalogs without compromising turnaround times.

- Narrow-Web Printing: Perfect for durable prime labels and sleeves in cosmetics or automotive industries.

Optimizing UV Curing for OPV Success

To maximize results, consider these factors:

- Photoinitiator Compatibility: Ensure varnish formulations match your UV system’s wavelength (e.g., 365-395 nm for LED).

- Substrate Suitability: Test materials like paper, film, or metallized stock to avoid adhesion issues.

- Lamp Intensity Control: Adjust UV output to prevent under- or over-curing, especially with heat-sensitive substrates.

The Future of Printing Finishes

As brands demand faster turnarounds and eco-friendly solutions, UV curing systems will remain indispensable. Innovations like hybrid UV/LED systems and low-migration varnishes are pushing boundaries further. Printers adopting this technology gain a competitive edge—delivering vibrant, long-lasting products while meeting stringent sustainability goals.

From labels that endure harsh environments to luxury packaging that dazzles on shelves, UV-cured overprint varnishes redefine what’s possible. By integrating this advanced curing method, printers unlock new levels of efficiency, quality, and customer satisfaction.