How UV Curing Systems Revolutionize Metallic and Special Effect Printing

In the competitive world of print production, achieving vibrant metallic finishes and eye-catching special effects demands precision, speed, and cutting-edge technology. UV curing systems have emerged as a game-changer, particularly for applications like label printing, flexography, offset, and narrow web printing. By integrating LED UV curing technology, printers unlock unmatched efficiency, durability, and design flexibility. Let’s explore how this innovation elevates metallic and specialty ink performance across key printing methods.

1. Instant Curing for Sharper Metallic Details

Metallic inks and foils rely on reflective particles to create lustrous finishes. Traditional drying methods, like heat or air drying, often cause ink spread or pigment settling, dulling the metallic effect. UV curing systems eliminate this issue by using targeted ultraviolet light to polymerize inks instantly.

In label printing, where fine details matter, LED UV curing locks metallic particles in place before they disperse. This results in crisp lines, brighter sheens, and consistent color reproduction—even on complex substrates like textured films or metallicized papers.

2. Enhanced Special Effects with Reduced Waste

Special effect inks—such as gloss, matte, or 3D textures—require precise curing to maintain their tactile or visual properties. Flexographic printing, widely used in packaging, benefits from UV curing’s ability to handle thick ink layers without blocking or smudging.

For example, high-gloss varnishes cure evenly under UV light, creating a smooth surface that resists scratches. Similarly, textured coatings retain their raised profiles, adding depth to luxury packaging or security labels. Faster curing also minimizes substrate warping, reducing material waste by up to 30% in high-speed runs.

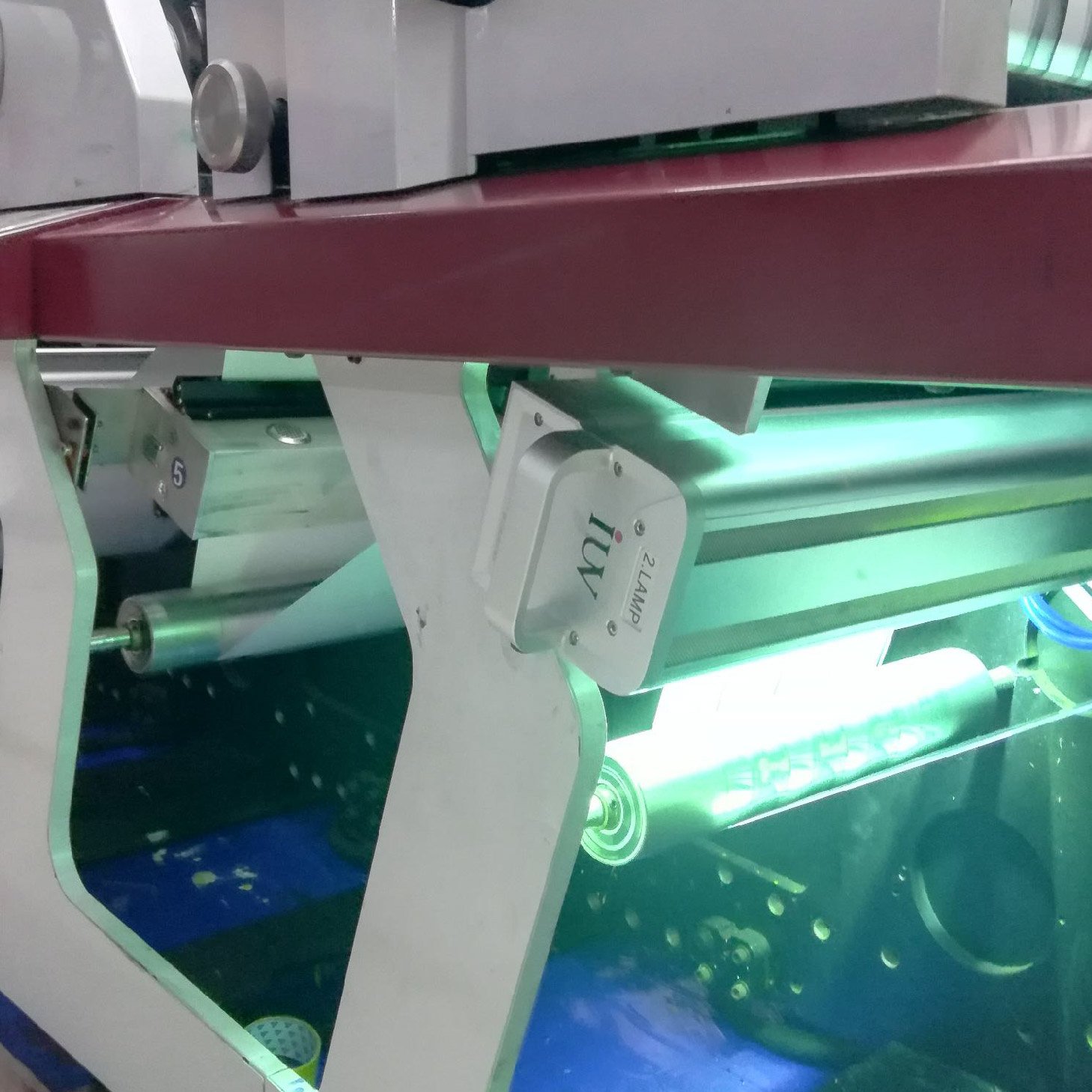

3. Narrow Web Printing: Speed Meets Versatility

Narrow web presses, common in labels and flexible packaging, thrive with UV systems due to their compact design and rapid curing capabilities. LED UV lamps generate minimal heat, preventing delicate films or thin papers from curling. This allows printers to use temperature-sensitive substrates like PVC or polyester while maintaining throughput.

Metallic inks cured with UV light also adhere better to non-porous materials, a critical advantage for waterproof labels or outdoor signage. Combined with quick job changeovers, narrow web printers achieve shorter lead times without sacrificing quality.

4. Offset Printing’s Renaissance in Specialty Finishes

Though offset printing traditionally relies on oil-based inks, UV-curable variants have expanded its capabilities. Sheetfed offset presses now produce metallic accents and holographic effects with sharper registration.

UV curing eliminates the need for powder sprays, reducing contamination risks in environments requiring high hygiene standards (e.g., food packaging). Additionally, instant curing allows immediate post-print processing, such as die-cutting or lamination, accelerating production cycles.

5. Sustainability Advantages of LED UV Technology

Modern LED UV systems consume 70% less energy than conventional mercury lamps and contain no ozone-producing components. Their long lifespan (20,000 hours) reduces maintenance costs and downtime. For eco-conscious brands, this aligns with sustainability goals while delivering premium finishes.

LEDs also emit a narrower wavelength spectrum, optimizing cure efficiency for metallic pigments prone to oxidation under excessive heat. This ensures long-lasting brilliance for retail displays or automotive decals exposed to UV light.

6. Overcoming Substrate Challenges

Printing metallic effects on absorbent materials like uncoated paper often leads to dull finishes. UV curing systems counteract this by sealing the ink surface immediately, preserving reflectivity. In hybrid printing setups, combining UV with traditional methods enables multi-textured effects—like a matte background with glossy metallic text—in a single pass.

7. Future-Proofing Print Workflows

As brands demand shorter runs and personalized designs, UV curing supports agile production. Its compatibility with digital inkjet systems opens doors for variable-data metallic printing—think serialized luxury labels or limited-edition packaging.

Moreover, advancements in UV ink formulations now offer softer finishes for tactile applications (e.g., cosmetic labels) or conductive inks for smart packaging.

Unlocking New Creative Dimensions

UV curing systems have redefined the boundaries of metallic and special effect printing. By delivering instant curing, superior adhesion, and eco-friendly operation, they empower printers to meet evolving market demands without compromise. Whether producing high-end labels, durable packaging, or intricate decals, integrating LED UV technology ensures consistent quality, faster turnaround, and endless creative possibilities.

For print providers aiming to differentiate their offerings, investing in UV curing isn’t just an upgrade—it’s a strategic leap toward dominating the premium print market.