How UV Curing Systems Revolutionize Print Durability and Scratch Resistance

In the competitive world of commercial printing, durability and scratch resistance are non-negotiable for high-value applications. UV curing systems have emerged as a game-changer, particularly for label, flexographic, offset, and narrow-web printing. By integrating LED UV technology, printers achieve faster production speeds, sharper finishes, and unmatched resilience. Let’s explore how this innovation elevates print performance across key processes.

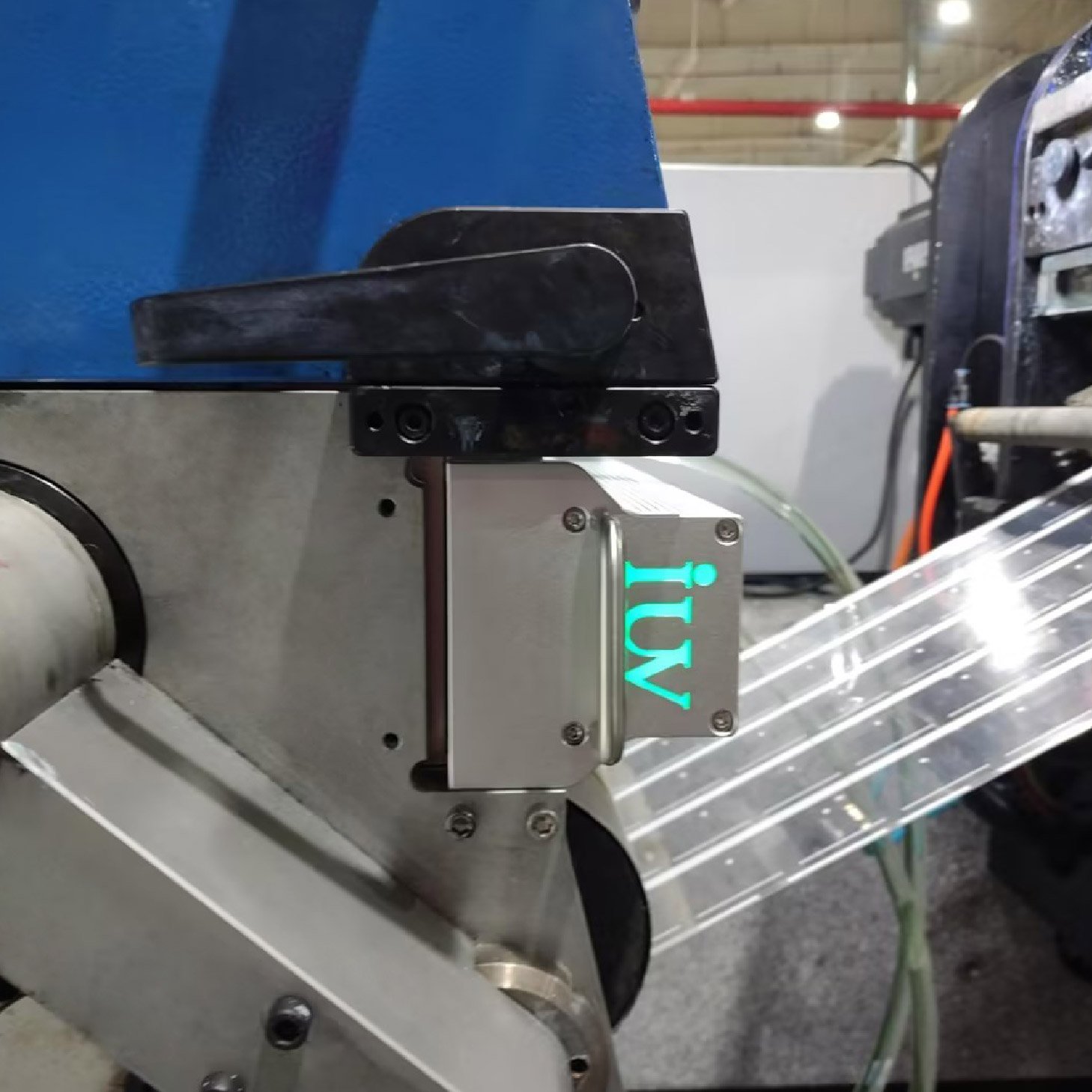

The Science Behind UV Curing

UV curing systems use ultraviolet light to instantly polymerize specially formulated inks, coatings, and adhesives. Unlike traditional drying methods, which rely on evaporation, UV technology triggers a photochemical reaction. When exposed to UV light, photoinitiators in the ink release free radicals, bonding molecules into a rigid, cross-linked matrix. This creates a surface resistant to abrasion, chemicals, and fading.

LED UV systems offer added precision, emitting targeted wavelengths (365-405 nm) for optimal curing without excess heat. This reduces energy consumption by up to 70% compared to mercury-vapor lamps while extending lamp life to 20,000 hours.

Label Printing: Enduring Performance Under Pressure

Labels face constant wear from handling, moisture, and UV exposure. UV-cured inks excel here, forming a protective layer that resists:

- Scuffing during bottling or transportation

- Friction in retail environments

- Degradation from outdoor sunlight

For wine labels, cosmetic packaging, or industrial equipment tags, UV curing ensures barcodes and graphics remain legible throughout the product lifecycle.

Flexographic Printing: Speed Meets Durability

Flexo printers prioritize high-speed production for packaging and films. Conventional solvent-based inks require lengthy drying times, but UV curing eliminates bottlenecks. Prints cure in milliseconds, allowing immediate cutting, folding, or stacking.

The hardened UV ink layer also withstands:

- Abrasion from automated filling lines

- Chemical contact (e.g., cleaning agents on food packaging)

- Flexing without cracking on corrugated substrates

Offset Printing: Premium Finish with Heavy-Duty Protection

Sheetfed offset applications like luxury packaging demand flawless aesthetics and durability. UV coatings applied inline provide a glossy or matte finish while shielding against:

- Fingerprints and smudges

- Scratches during shipping

- Water spots or oil penetration

For metalized or textured stocks, UV curing prevents ink offsetting and ensures crisp detail retention.

Narrow-Web Printing: Precision for Specialty Applications

Narrow-web presses handle sensitive materials like heat-transfer films and medical labels. LED UV’s cool operation prevents substrate distortion, even on thin PET or PVC films. The instant cure also enables:

- Tight registration for multi-layer security prints

- Resistance to sterilization processes (autoclaving, gamma radiation)

- Adhesion on non-porous surfaces like synthetic papers

Key Advantages of UV-Cured Prints

- Scratch Resistance: Cross-linked polymers create a surface hardness comparable to polycarbonate.

- Chemical Inertness: Resists solvents, acids, and alkalis in industrial or cleaning environments.

- Weatherproofing: UV blockers in inks prevent color fading under prolonged sunlight exposure.

- Eco-Friendly: 100% solid formulations release zero VOCs, aligning with sustainability goals.

Optimizing UV Systems for Maximum ROI

To leverage UV curing effectively:

- Match lamp intensity to ink opacity and line speed

- Use nitrogen inerting to prevent oxygen inhibition in deep-cure applications

- Maintain reflector cleanliness to ensure consistent energy delivery

- Partner with ink suppliers for formulations tailored to your substrates

Future-Proofing Print Performance

As brands demand longer-lasting packaging and regulatory pressures mount, UV curing systems provide a scalable solution. Advances in LED efficiency and hybrid curing (UV/EB) promise even greater versatility for emerging materials like biodegradable films.

For printers seeking to reduce waste, boost throughput, and deliver indestructible graphics, UV technology isn’t just an upgrade—it’s a strategic imperative. By adopting these systems now, businesses position themselves as leaders in quality-driven markets where durability defines value.

Explore UV curing integrations for your pressroom to unlock faster turnaround times, lower operational costs, and client retention through superior product performance.