How to Optimize Print Quality with LED UV Curing Systems in Modern Printing

The shift toward LED UV curing systems has revolutionized print quality across label, flexographic, offset, and narrow-web printing. Unlike traditional mercury-based UV systems, LED technology delivers instant, energy-efficient curing with precision. For printers aiming to reduce waste, boost color consistency, and achieve faster production speeds, mastering LED UV optimization is critical. Below, we break down actionable strategies for maximizing print performance in key applications.

1. Label Printing: Precision for High-Resolution Graphics

Label printers demand sharp text, vibrant colors, and resistance to abrasion. LED UV curing excels here by instantly hardening inks without heat, preventing substrate distortion. To optimize:

- Control Ink Film Thickness: Thin, even layers cure faster and reduce shadowing. Use anilox rollers with lower volume cells (4-6 BCM) for fine details.

- Match Wavelength to Photoinitiators: Ensure inks are formulated for LED wavelengths (365-405 nm). Mismatched settings cause incomplete curing.

- Adjust Conveyor Speed: Test curing at incremental speeds. LED systems often handle 50-100 m/min, but substrate type and ink opacity affect ideal settings.

2. Flexographic Printing: Minimizing Dot Gain in Flexible Packaging

Flexo printers face challenges like dot gain and ink spreading on non-porous films. LED UV’s rapid curing locks ink dots in place, improving print contrast. Key tips:

- Optimize Plate Hardness: Use softer plates (55-65 Shore A) to improve ink transfer while maintaining dot integrity.

- Reduce Viscosity: Thin UV inks flow evenly, reducing roller stripping. Add approved diluents sparingly to avoid curing issues.

- Monitor Lamp Intensity: Regularly check LED output with radiometers. Intensity drops over time, leading to tacky prints.

3. Offset Printing: Enhancing Color Stability on Coated Stocks

Offset printers benefit from LED UV’s ability to cure thick ink films on coated papers without blistering. For premium results:

- Prevent Oxidation: Use nitrogen inertization to eliminate oxygen inhibition, ensuring full curing of deep colors (e.g., blacks, metallics).

- Balance Ink-Water Ratio: Excess dampening solution slows curing. Maintain pH levels (4.8-5.2) and conductivity (800-1,500 µS/cm).

- Calibrate Drying Distance: Position LED lamps 5-10 cm from substrates. Too close risks overheating; too far reduces irradiance.

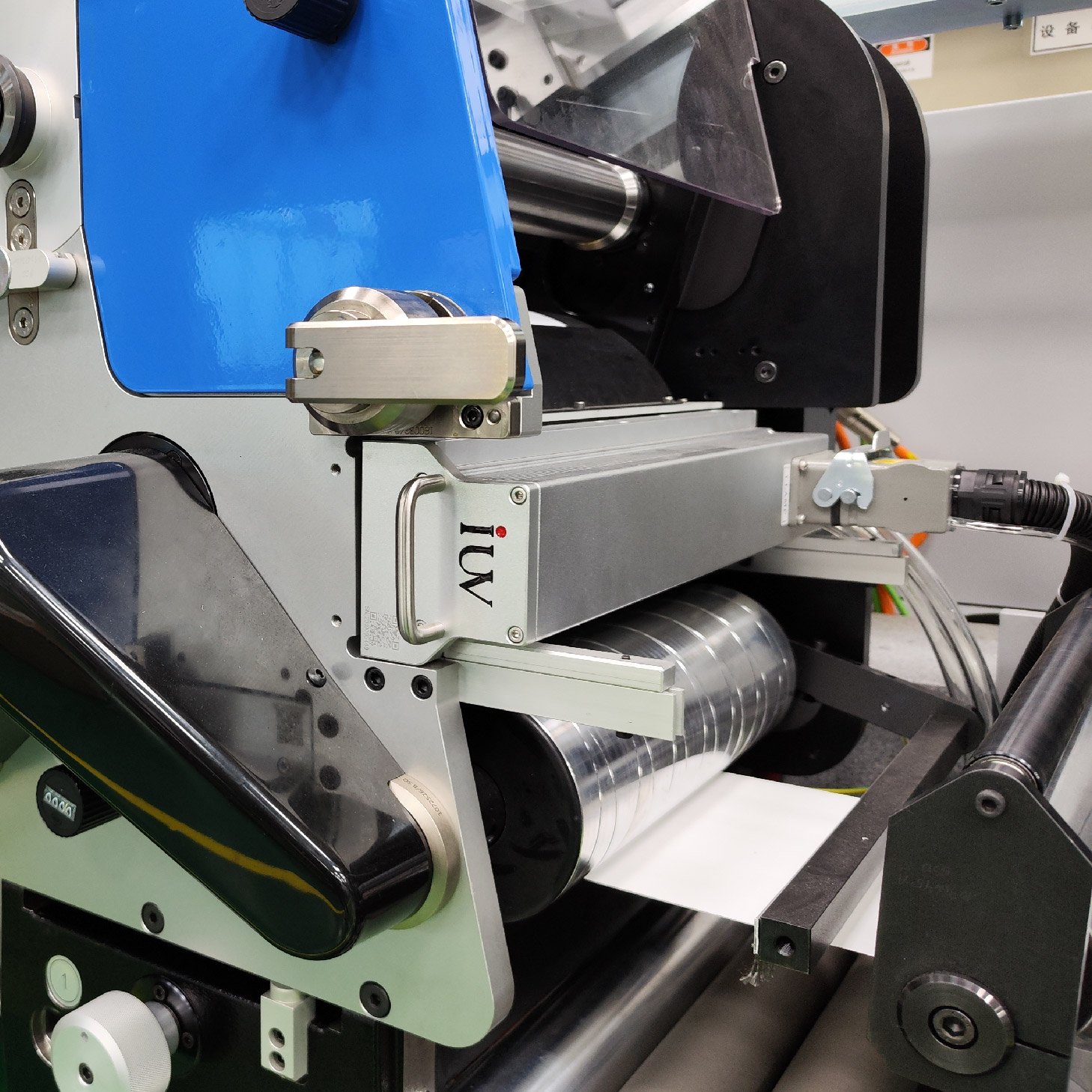

4. Narrow-Web Printing: Multi-Process Efficiency

Narrow-web hybrid presses combine flexo, screen, and digital processes. LED UV’s compatibility with heat-sensitive materials (e.g., PET, shrink sleeves) makes it ideal. Optimize by:

- Sequential Curing: Use multiple LED units for layered effects (e.g., primer metallic ink overprint varnish).

- Test Adhesion: Perform cross-hatch tests after curing. Poor adhesion often stems from insufficient energy density (≥300 mJ/cm²).

- Manage Substrate Reflectivity: Reflective materials (foils) require higher irradiance. Adjust lamp power or slow web speed.

Critical Factors in LED UV Curing Performance

Regardless of application, three variables dictate success:

- Irradiance (W/cm²): Higher intensity shortens curing time but risks overheating. Match to ink manufacturer specs.

- Spectral Match: Confirm LED peak wavelength aligns with the ink’s photoinitiator response curve.

- Oxygen Inhibition: Use inert gas or additives to counter surface tackiness in high-humidity environments.

Troubleshooting Common LED UV Issues

- Tacky Prints: Increase irradiance or reduce line speed. Check for expired photoinitiators.

- Ink Cracking: Over-curing makes films brittle. Lower UV dose or add flexibilizers.

- Color Shift: Ensure lamps emit consistent UV-A/UV-V spectra. Aging LEDs may skew wavelengths.

Final Recommendations

LED UV curing systems unlock unmatched print quality but require precise calibration. Partner with ink suppliers to validate formulations, and conduct routine maintenance on LED arrays. For mixed-substrate jobs, perform test runs to fine-tune energy settings. By prioritizing spectral alignment, process control, and substrate compatibility, printers can achieve glossier finishes, sharper details, and faster turnaround—securing a competitive edge in premium print markets.

Invest in staff training to interpret curing data and adjust parameters dynamically. As LED UV technology evolves, staying updated on advancements (e.g., dual-wavelength lamps, modular systems) will future-proof operations.