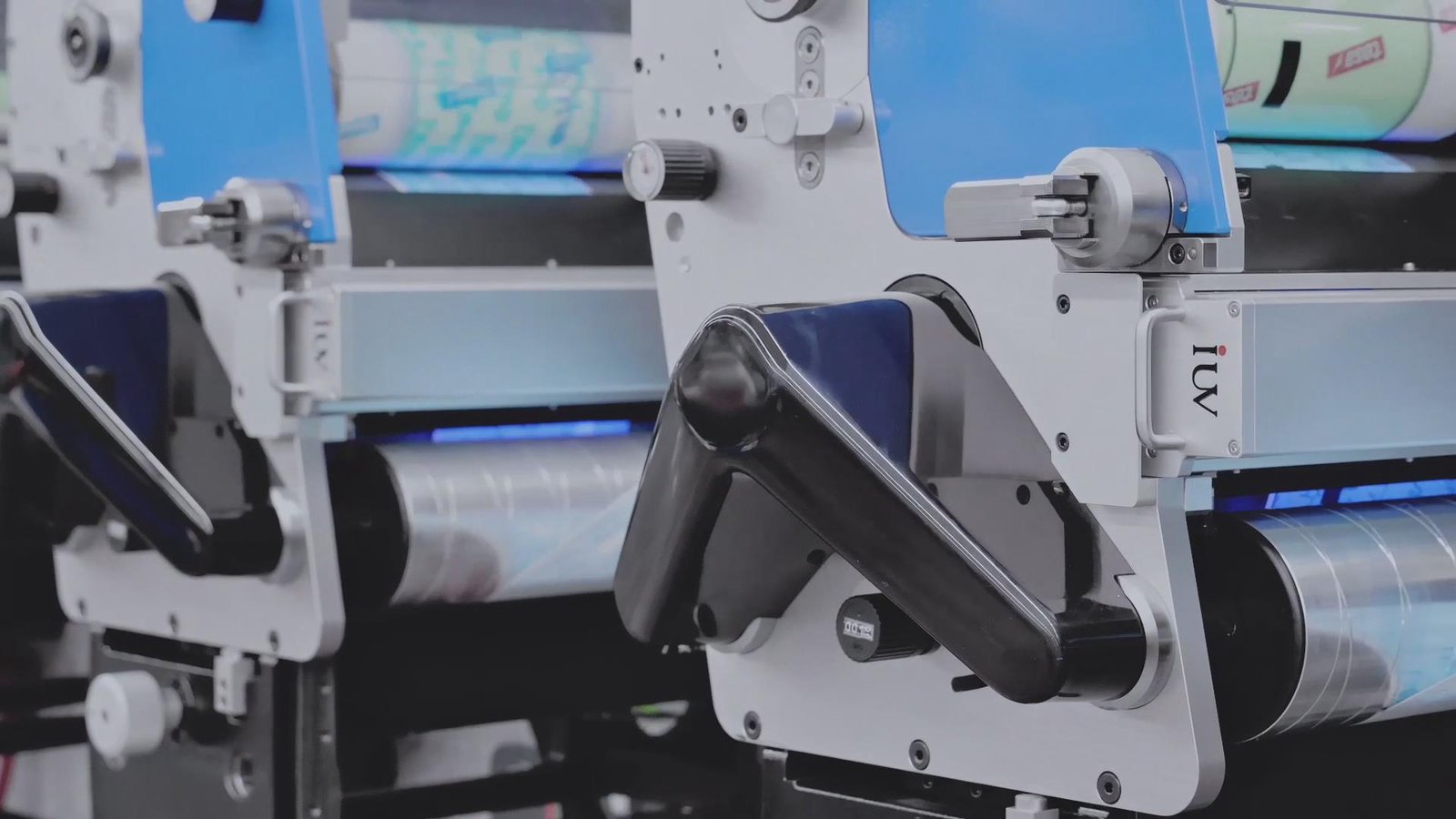

Flexographic printing—whether for labels, packaging, or narrow-web applications—has always demanded speed, precision, and adaptability. But as sustainability goals tighten and energy costs rise, the industry’s reliance on traditional UV curing methods (like mercury-vapor lamps) is hitting a wall. Enter LED UV curing: a game-changer for flexo, offset, and label printing. Let’s break down why this tech isn’t just an upgrade—it’s a necessity for shops aiming to stay competitive.

1. Energy Efficiency That Cuts Costs (Without Sacrificing Speed)

Traditional mercury lamps waste up to 70% of their energy as heat. LED UV systems, by contrast, convert 95% of energy into targeted UV light. For a mid-sized label printer running 24/5, switching to LED can slash energy bills by $15,000–$20,000 annually.

But efficiency isn’t just about dollars. Heat generation from mercury lamps warps thin films and forces press shutdowns for cooling. LED’s cool operation lets you print heat-sensitive materials like PE films or shrink sleeves without distortion. No downtime. No waste.

2. Instant On/Off: No More Waiting for Lamps to Warm Up

Mercury lamps need 5–15 minutes to reach full intensity. LED UV systems activate at 100% power in microseconds. For short runs—think craft beer labels or limited-edition packaging—this eliminates ramp-up delays. One Ontario-based printer reduced job changeover time by 40% after switching to LED, squeezing in 3–4 extra jobs per shift.

3. Ditch the Ozone, VOCs, and Toxic Bulbs

Mercury lamps emit ozone, requiring costly ventilation upgrades. Their bulbs also contain mercury, demanding hazardous waste protocols. LED UV systems produce zero ozone and contain no toxic materials. In California, where air quality regulations are brutal, printers using LED report 30% lower compliance costs.

Plus, LED’s precise wavelength (365–405 nm) works with VOC-free inks. No solvents. No off-gassing. Retailers like Whole Foods now prioritize suppliers using UV-LED for cleaner packaging.

4. Crisper Prints, Fewer Defects

LED UV’s narrow wavelength range cures inks and coatings more uniformly. For fine text on pharmaceutical labels or metallic effects on cosmetic packaging, this means:

- Sharper dot reproduction (no halo effects)

- Consistent color density across runs

- Zero tackiness post-cure

A European narrow-web printer saw defect rates drop from 5% to 0.8% after adopting LED, saving €50,000 yearly in reprints.

5. Longer Lifespan, Lower Maintenance

A mercury lamp lasts 1,000–2,000 hours. LED UV arrays? 20,000–30,000 hours. That’s 2–3 years of nonstop production without bulb replacements. Minnesota-based Taylor Packaging cut maintenance labor by 70% post-LED adoption—no more nightly lamp checks.

The Bottom Line for Flexo Printers

LED UV isn’t a “nice-to-have.” It’s a strategic pivot. With ROI periods under 18 months (thanks to energy/maintenance savings) and brands demanding greener supply chains, sticking with mercury lamps risks losing clients to forward-thinking competitors.

Ready to future-proof your shop? Start with a hybrid press—retrofit LED units alongside existing systems. Test it on jobs with tight tolerances (e.g., medical labels). You’ll see the difference in waste reduction, speed, and client feedback.