If you’re in the label printing game, you’ve probably heard the buzz about LED UV curing. But what makes it a game-changer for narrow web presses? Let’s break it down—no jargon, no fluff—just actionable insights for printers, engineers, and decision-makers.

Why LED UV Curing? Spoiler: It’s Not Just About Speed

Narrow web label presses thrive on precision. Whether you’re running flexo, offset, or hybrid setups, curing is the make-or-break step. Traditional mercury lamps work, but they’re like gas-guzzling cars in an electric era. LED UV curing slashes energy use by up to 70%, runs cooler, and eliminates ozone emissions. For labels demanding sharp detail (think: cosmetic sleeves or pharma packaging), LED UV ensures ink stays put without substrate warping.

Pro Tip: LED systems hit full intensity instantly. No warm-up. No cooldown. Just hit “print” and go.

Flexo vs. Offset: Where LED UV Shines

Let’s get technical—but keep it simple.

- Flexographic Printing

- The Challenge: Solvent-based inks can bleed on porous materials (e.g., kraft paper).

- The Fix: LED UV inks cure on demand, locking pigments into place. Bonus: No VOC headaches.

- Ideal For: Pressure-sensitive labels, shrink sleeves.

- Offset Printing

- The Challenge: Heat from conventional curing can distort thin films or metallized substrates.

- The Fix: LED’s cold cure preserves material integrity. Perfect for PET or BOPP labels.

Real-World Win: A craft brewery switched to LED UV for their limited-edition labels. Result? Zero smudging on textured paper, 40% faster job turnover.

The Science Bit (Without the Boring Lecture)

LED UV curing uses specific wavelengths (365-405 nm) to trigger photoinitiators in inks/coatings. Unlike mercury lamps, which blast a broad spectrum, LEDs target only what’s needed. Less energy waste, fewer heat-related issues.

Key Terms Made Simple:

- Photoinitiators: Chemicals that “activate” when hit by UV light, hardening the ink.

- Peak Irradiance: How intensely the light hits the substrate. Higher isn’t always better—match it to your ink’s requirements.

5 Questions Printers Forget to Ask (But Should)

- “Will my existing inks work?”

Maybe. Hybrid inks exist, but dedicated LED UV formulations deliver sharper results. Test before full adoption. - “What’s the ROI timeline?”

Typical payback: 12-18 months via energy savings, reduced downtime, and lower HVAC costs (no heat to counteract). - “Can it handle white ink?”

Yes, but white pigments reflect UV light. Solution: Higher irradiance or dual-cure systems. - “Is maintenance a nightmare?”

LED arrays last 20,000 hours. Swap modules in minutes—no toxic mercury disposal. - “What about hybrid setups?”

Pair LED UV with water-based inks for eco-friendly labels. Works like a charm on paper stocks.

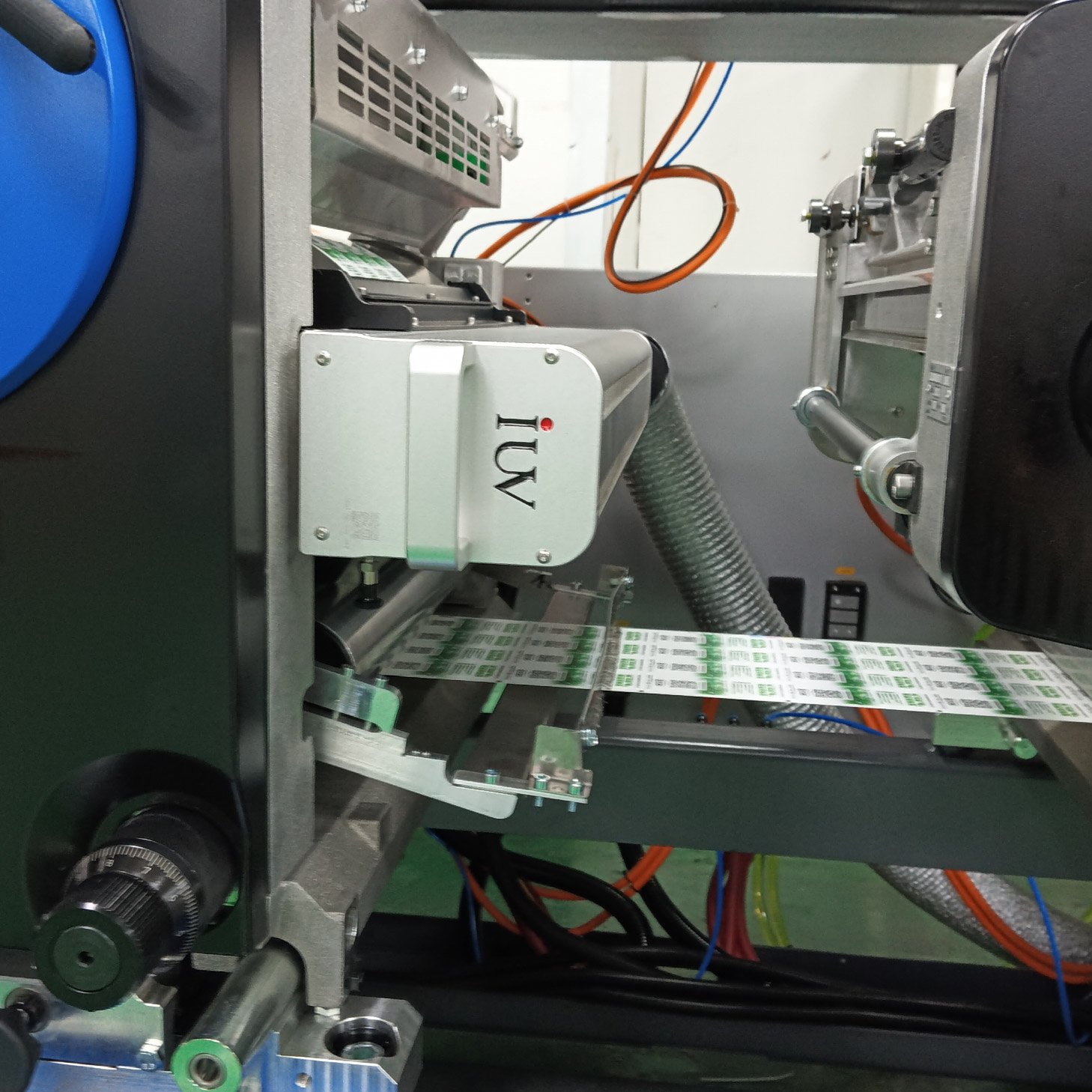

Case Study: LED UV in Action

Client: A mid-sized label converter struggling with wine bottle labels.

Problem: Heat-sensitive synthetic substrates warped under traditional curing.

Solution: Installed an LED UV module on their narrow web press.

Outcome:

- 30% reduction in waste (no more curled edges).

- Expanded client base to include luxury brands needing metallic finishes.

Future-Proofing Your Press

The label industry’s shifting toward shorter runs and customization. LED UV’s flexibility lets you pivot fast:

- Swap inks on the fly without reconfiguring curing settings.

- Print on heat-sensitive materials (hello, biodegradable films).

- Meet sustainability mandates without sacrificing quality.

Bottom Line: LED UV isn’t just a tech upgrade—it’s a market differentiator.

Need More Juice?

- For Engineers: Dive into spectral output charts. Match LED wavelengths to your ink supplier’s specs.

- For Managers: Calculate your energy savings [here] (hypothetical link).

- For Press Operators: Train your team on irradiance adjustments—overcuring kills efficiency.

LED UV curing isn’t the future. It’s the now. Time to flip the switch. 🔌