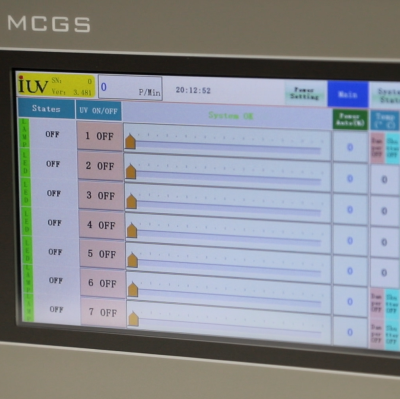

Proper selection of the UVLED curing machine’s output power is crucial for achieving optimal curing results.

Different UV-sensitive materials require specific energy and wavelength ranges for effective curing.

Manufacturers must carefully adjust the power output of the UVLED machine to match the requirements of the particular UV adhesive, ink, or varnish being used.

Failure to do so can result in incomplete or inconsistent curing, leading to quality issues with the final product.

-

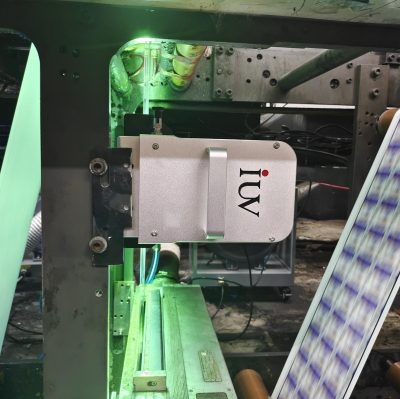

Ideal Distance

The distance between the UVLED light source and the substrate surface should be carefully controlled, typically between 5-10mm, for better curing effects.

-

Incorrect Distances

Improper illumination distances can lead to either overheating or insufficient curing of the UV-sensitive coatings, compromising the final product quality.

-

Maintaining Consistency

Manufacturers must ensure consistent illumination distance throughout the curing process to maintain a uniform and effective curing result.

-

UV Glue

UV glue typically requires a wavelength band of 365nm for effective curing.

-

UV Ink

UV ink commonly utilizes a wavelength of 395nm for optimal curing.

-

Matching Wavelength

Manufacturers must use a UVLED curing machine with the appropriate wavelength range to ensure the effective curing of the specific UV-sensitive material being used.

-

Importance of Quality

The quality of LED lamp beads used in the UVLED curing machine directly impacts the reliability and performance of the equipment. Higher-quality lamp beads, often imported from Japan or South Korea, yield better curing effects.

-

Cost Considerations

While higher-quality lamp beads may come at a higher cost, the improved curing performance and reliability can ultimately lead to better product quality and reduced manufacturing waste, potentially offsetting the initial investment.

-

Maintaining Performance

Regularly inspecting and replacing the LED lamp beads, as recommended by the manufacturer, is crucial for maintaining the optimal performance of the UVLED curing machine over time.

-

Thin Coatings

Thin UV coatings may result in poor surface color and cracking, as the curing process is not sufficient to fully harden the material.

-

Thick Coatings

Thicker UV coatings require longer irradiation times and can cause substrate deformation due to excessive heat buildup during the curing process.

-

Achieving Optimal Thickness

Manufacturers must carefully control the coating thickness to ensure effective and consistent curing, balancing the needs of the material and the substrate.

-

Monitoring and Adjustments

Regular monitoring of the coating thickness and making necessary adjustments to the application process are crucial for maintaining optimal curing results.

Ambient Temperature

Direct Sunlight

Controlling Conditions

-

Insufficient Irradiation

Tackiness or incomplete curing of the UV coating, resulting in quality issues.

-

Excessive Irradiation

Aging and degradation of the UV coating due to prolonged exposure to UV light, leading to a reduction in the coating’s performance and lifespan.

-

Optimal Irradiation

Adjusting the irradiation duration or conveyor belt speed to ensure the substrate receives the appropriate UV light energy for complete and consistent curing.

Printer must carefully monitor and adjust the irradiation duration or conveyor belt speed to provide the optimal UV light exposure for the specific UV-sensitive material being used, ensuring a high-quality, fully cured final product.