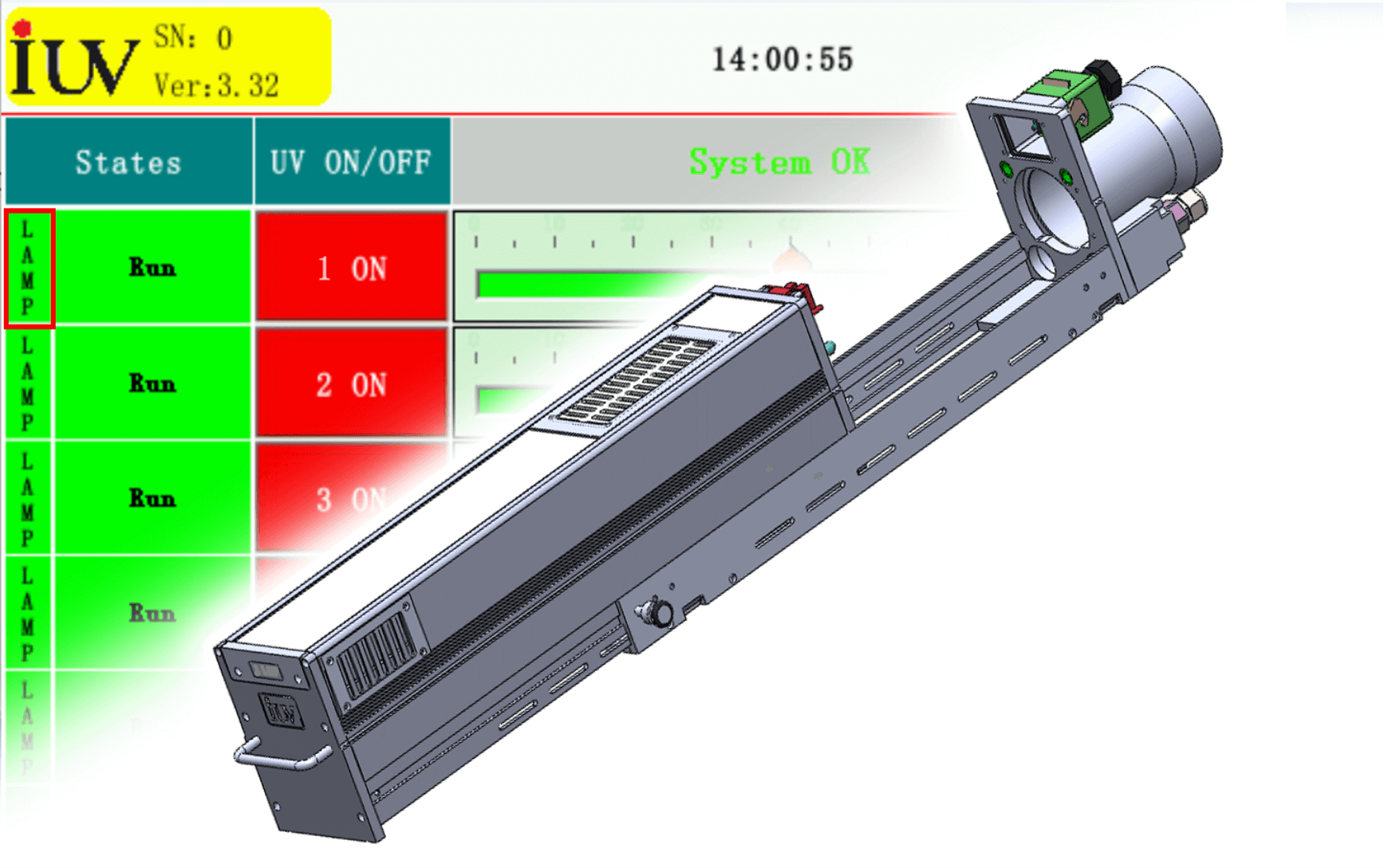

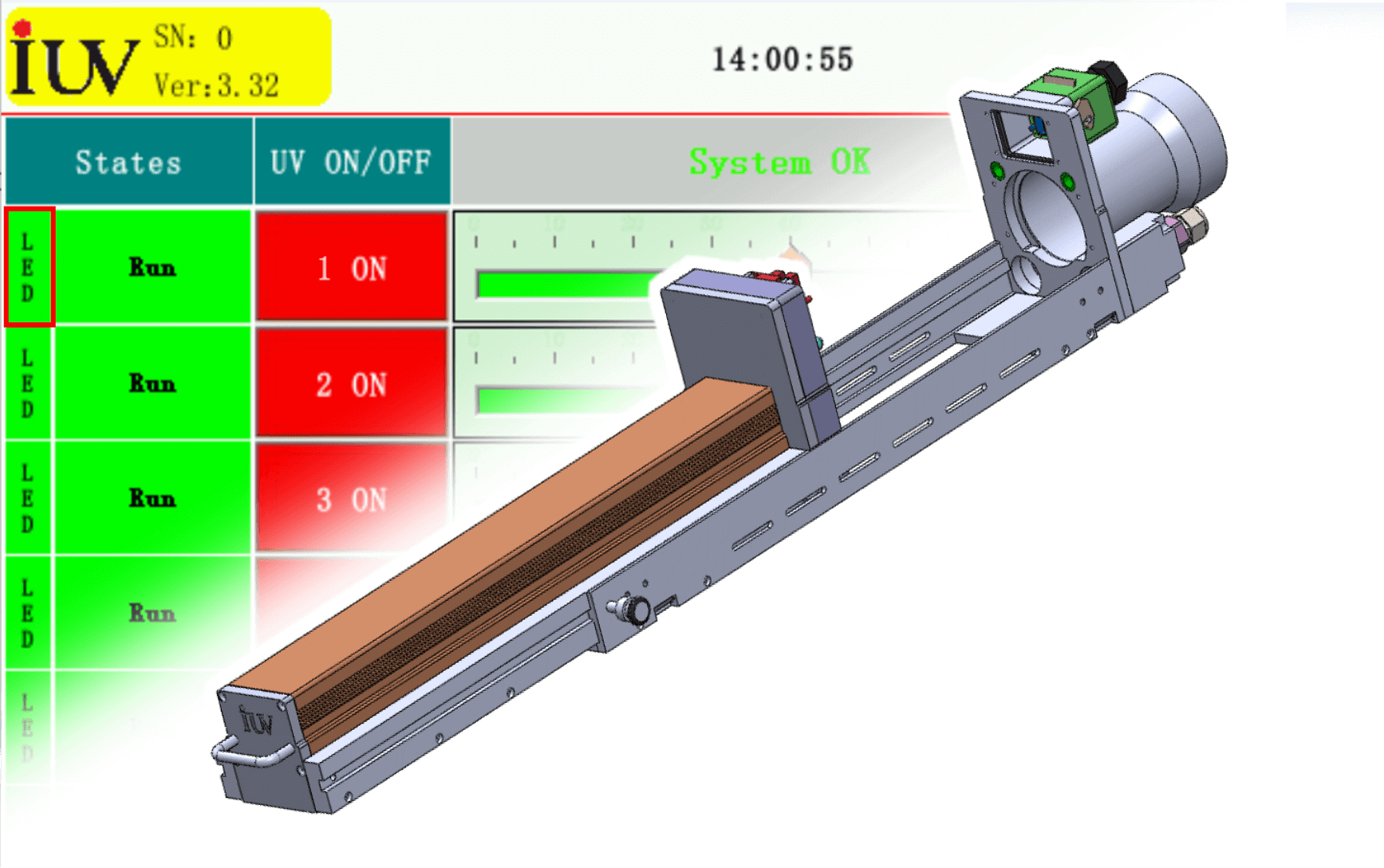

IUV’s Mercury & LED Exchanging Curing Technology is a cutting-edge innovation that offers the flexibility to switch between mercury UV lamps and LED UV lamps within the same curing system.

This technology allows users to choose the most suitable curing method for different applications, materials, or production processes.

By seamlessly integrating both mercury and LED UV curing capabilities, IUV’s technology provides versatility, efficiency, and adaptability, catering to a wide range of curing requirements in the printing, coating, and converting industry.

- The same power module contains two software algorithms. According to different load, the power supply mode can be automatically switched. lt can supply power to mercury lamp or LED light source.

- The two lamp boxes can be freely plugged and unplugged, and the system can automatically identify. Without any other human operation, the two lamp boxes can be switched freely to meet the various needs of customers for curing, improve the production efficiency and reduce production costs.

- In IUV’s uv retrofit processing, the UV & LED hybrid interchanging technology brings great convenience and flexibility to work, and also greatly reduces our customer‘s costs

- Mercury lamp, halogen lamp and LED Lamp box could be inserted and pulled out freely.

- The system could be identified automatically without other operation.

- Keep the water cooling structure of LED Lamp box, high-efficiency and environment protection.

- Complement each other,adapt to all the requirement of the printing curing process.

- Reduce the cost, and improve the production efficiency.

- The variety of printing products which determine the printing ink and a variety of materials. And some materials are not suitable for the curing characteristics of LED.

- The position of adopting the special ink color group is in a state of constant change.

- The switching operation of manufacturing technique, it requires the continuous improvement of the production efficiency.

- With the promotion of energy saving and emission reduction, the manufacturing technique is constantly improving.

- Mercury lamp, halogen lamp and LED Lamp box could be inserted and pulled out freely.The system could be identified automatically without other operation.

- Keep the water cooling structure of LED Lamp box,high-efficiency and environment protection.

- Complement each other,adapt to all the requirement of the printing curing process.