- 70% Electricity Saving

- 80% Maintenance Saving

- Labor Cost Saving

- No Consumable Parts

- Long Lifespan

- Minimizing Material Waste

70% energy saving,no mercury or ozone. Reduce your carbon footprint and align your business with environmental sustainability goals.

Eliminate hazardous materials and reduce UV radiation exposure , Protect your workforce and maintain a healthy working environment.

LED UV systems, with their lower heat and controlled UV output, are more compatible with a wider range of materials, including those designed for recycling.

Fast Printing

Better Color

Less Defects

Material Compatibility

Print Product Durability

Reduced Ink Migration

Overprint Registration

Customizable Solutions

Real-time Data Link

Data-Driven Insights

Automated UV Controls

Cloud-Local Data Interaction

Legal Requirements

Sustainable Requirements

Competitive Requirement

70%', greatly reducing the cost of your competitors, if you do not use LED, you will lose the market advantage.

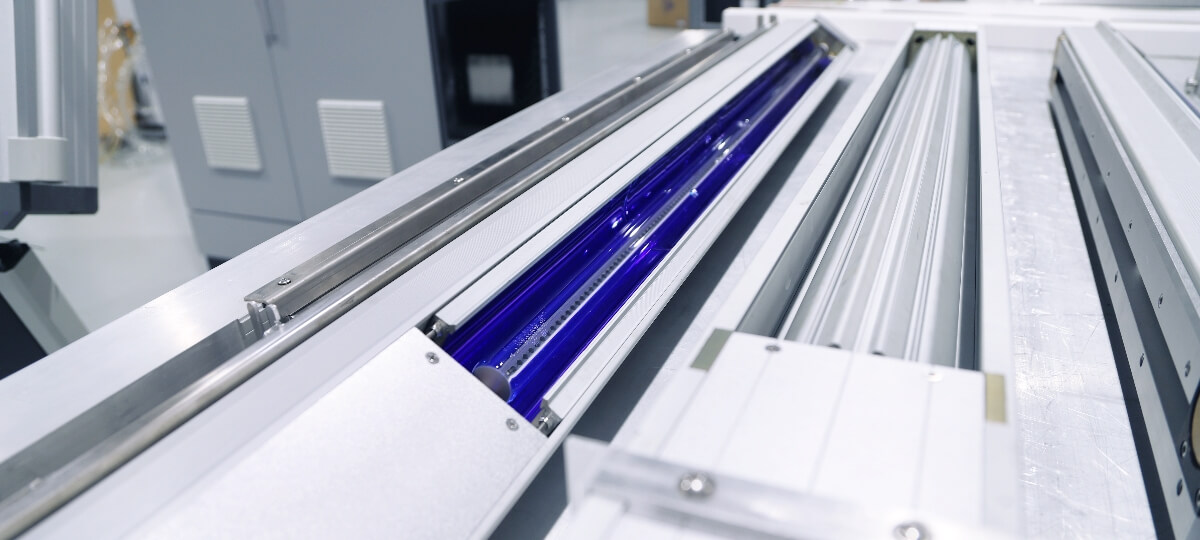

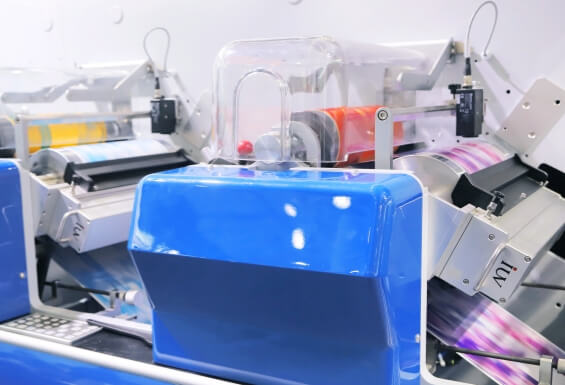

lUV developed unique design specially for UV LED upgrade project and handle over 600 LED uv curing upgrading and UV retroft projects every year

Our UV LED system has been functioning in almost any model of printing press in the market.

We can provide valuable insights and help you with the most suitable LED UV curing solution for you!