Mercury UV vs LED UV : The Advantages of LED UV Curing Systems Over Traditional Mercury UV Lamps

The printing and curing industry is continuously evolving, with new technologies emerging to address the growing demand for efficiency, sustainability, and high-quality results. One such technology that has gained significant traction in recent years is LED UV curing systems. These systems are increasingly being adopted as a superior alternative to traditional mercury lamps. This article explores the key advantages of LED UV curing systems over traditional mercury lamps and highlights the numerous benefits they offer to the printing industry.

The Limitations of Traditional Mercury UV Curing Lamps

Mercury lamps have been the standard in UV curing for decades, but they come with several limitations:

-

Environmental Impact: Mercury lamps contain harmful mercury, which poses environmental and health risks during disposal and operation.

-

Energy Inefficiency: These lamps consume significantly more energy than LED systems, leading to higher operational costs.

-

Short Lifespan: Mercury lamps have a relatively short lifespan, requiring frequent replacements and increasing maintenance costs.

-

Heat Generation: Mercury lamps emit a substantial amount of heat, which can affect the curing process and the surrounding environment.

-

Warm-Up Time: Mercury lamps require a warm-up period to reach maximum intensity, leading to delays in production.

The Advantages of LED UV Curing Systems

LED UV curing systems offer several distinct advantages over traditional mercury lamps:

Environmental Friendliness

-

-

No Mercury Content: LED UV systems do not contain mercury, eliminating the environmental and health risks associated with mercury lamps.

-

Reduced Energy Consumption: LED UV curing systems are much more energy-efficient, consuming up to 80% less energy than traditional mercury lamps. This reduction in energy consumption translates to lower operational costs and a smaller carbon footprint.

-

Lower Heat Emission: LED UV systems operate at lower temperatures, reducing the need for heat extraction and minimizing the environmental impact.

-

Enhanced Performance

-

-

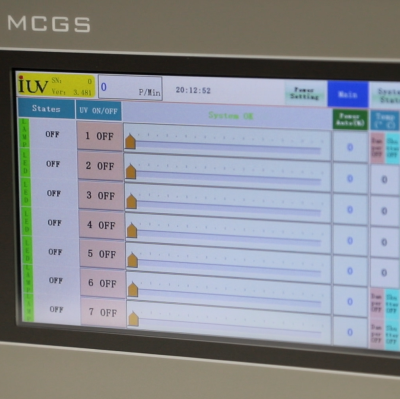

Instant On/Off Capability: LED UV systems can be powered on and off instantly, eliminating the need for warm-up times and increasing production efficiency.

-

Longer Service Life: LED UV systems have a much longer lifespan, typically lasting between 25,000 to 50,000 hours, significantly reducing maintenance and replacement costs.

-

Uniform Curing: LEDs provide a more uniform distribution of light across the cure area, resulting in more consistent and higher-quality curing results.

-

Wavelength Flexibility: LED UV systems can be customized to emit specific wavelengths, allowing for more precise and effective curing of various materials.

-

Cost Efficiency

-

-

Reduced Operational Costs: The lower energy consumption and longer lifespan of LED UV systems lead to significant cost savings over time.

-

Lower Maintenance Costs: With fewer components to replace and less frequent maintenance, LED UV systems reduce the total cost of ownership.

-

Improved Safety

-

No Toxic Substances: LED UV systems do not release harmful substances like ozone or mercury vapors, making them safer for operators and the environment.

-

Reduced Heat Exposure: The lower heat emission of LED UV systems reduces the risk of heat-related damage to materials and improves workplace safety.

Applications and Future Outlook

LED UV curing systems are versatile and can be applied in various industries, including:

-

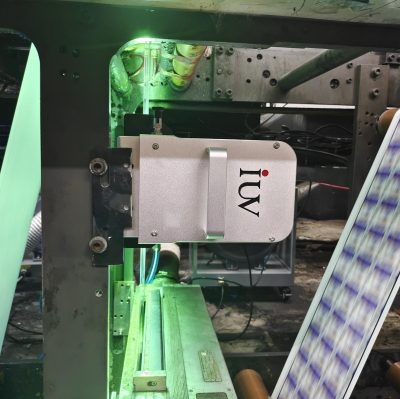

Printing Industry: LED UV systems are ideal for flexo, offset, post-press, and digital printing applications.

-

Coating and Adhesive Applications: LED UV systems offer significant benefits in coating and adhesive applications, providing faster curing and higher durability.

-

Water Treatment: LED UV systems are increasingly being used in water treatment for their environmental benefits and effectiveness.

-

Disinfection: LED UV systems are effective in disinfecting surfaces and air, with applications in healthcare, food processing, and HVAC systems.

The transition from traditional mercury lamps to LED UV curing systems represents a significant advancement in UV curing technology. LED UV systems offer numerous advantages, including environmental friendliness, enhanced performance, cost efficiency, and improved safety. As the industry continues to evolve, LED UV curing systems are poised to play an increasingly important role in meeting the demands of modern printing and curing applications.

Contact IUV LED UV Experts