How Do UV Curing Systems Work in Label Printing?

UV curing systems have revolutionized the label printing industry by providing a faster, more efficient, and environmentally friendly alternative to traditional drying methods. This article explores how UV curing systems work specifically within the context of label printing, highlighting their benefits and applications.

The Science Behind UV Curing in Label Printing

Photopolymerization Process

UV curing in label printing relies on the process of photopolymerization. This involves using ultraviolet (UV) light to rapidly cure or solidify UV-curable inks and coatings. When these materials are exposed to UV light, photoinitiators within the ink or coating absorb the energy, triggering a chemical reaction that bonds monomers and oligomers into polymers. This results in the hardening or “curing” of the material, transforming it from a liquid or semi-solid state to a solid, durable finish in milliseconds.ents.

UV Wavelengths and Intensity

In label printing, UV curing systems typically operate within specific wavelength ranges, most commonly between 200nm and 400nm. The optimal wavelength depends on the specific application and material being cured. Higher intensity UV light generally results in faster curing times, which is particularly beneficial in high-speed label printing environm

Components of a UV Curing System in Label Printing

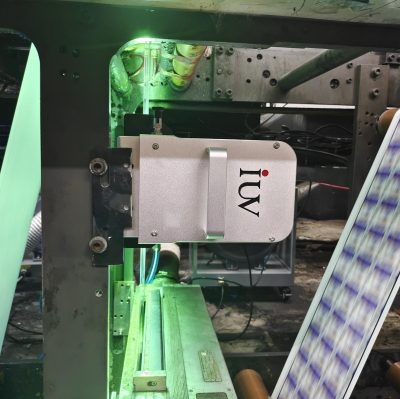

UV Light Source

The heart of a UV curing system in label printing is the UV light source, which can be either traditional mercury lamps or modern UV LED arrays. UV LEDs are increasingly preferred due to their longer lifespan (typically >30,000 hours), instant on/off capabilities, energy efficiency, and reduced heat emission. These characteristics make UV LEDs particularly suitable for label printing applications where quick curing and consistent output are essential.

Cooling System

Effective thermal management is crucial for maintaining performance and longevity. Most UV curing systems in label printing employ cooling systems to prevent overheating of components and maintain optimal operating temperatures. Water cooling systems are commonly used for high-power applications to ensure stable performance.

Power Supply

The power supply unit delivers the necessary electrical power to the UV light source while maintaining precise control over voltage and current. Advanced systems feature constant voltage-current control mechanisms that ensure stable performance even under varying loads, which is essential for consistent curing results in label printing.

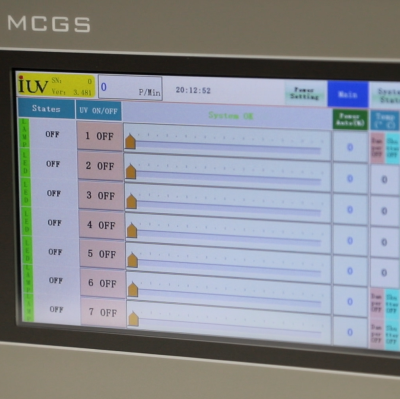

Control System

Modern UV curing systems in label printing incorporate sophisticated control systems that manage various aspects of operation. These include automatic sensing technology to detect material position and width, remote monitoring for real-time adjustments, intelligent automation to dynamically adjust energy output, and diagnostic capabilities to identify potential issues before they cause production delays.

The Curing Process in Label Printing

Application of Ink or Coating

The UV-curable ink or coating is applied to the label substrate using printing techniques such as flexography, offset printing, or digital inkjet printing. These methods are chosen based on the specific requirements of the label design, substrate, and production volume.

Exposure to UV Light

Immediately after application, the printed labels pass under UV light sources. The photoinitiators in the ink absorb the UV energy, triggering the polymerization process. The intensity and duration of exposure are carefully controlled to achieve optimal curing results, ensuring consistent quality across the entire label surface.

Instant Curing

Within milliseconds to seconds, the ink or coating transforms from a liquid to a solid state, forming a durable, high-quality finish on the label. This instant curing allows for immediate handling and further processing of the labels, significantly reducing production cycle times.

Benefits of UV Curing Systems in Label Printing

Enhanced Print Quality

UV curing improves ink adhesion, resulting in more vibrant and accurate colors. The precise control of the curing process allows for finer details and higher resolution, making intricate designs and small text clearer. The instantaneous and uniform curing provided by UV LED systems ensure consistent print quality across the entire label surface, reducing smudging and ensuring repeatability.

Increased Productivity and Efficiency

Unlike traditional drying methods that require time for the ink to set, UV curing is almost instantaneous. This significantly speeds up the production cycle, allowing label manufacturers to meet tight deadlines and increase output. The longer lifespan of UV LED lamps (up to 20,000-50,000 hours) and lower maintenance requirements minimize downtime, ensuring continuous production.

Environmental Sustainability

UV LED curing systems consume significantly less power compared to conventional methods, leading to substantial energy savings and reduced operational costs. UV LED systems produce no ozone or mercury, and they eliminate the need for volatile organic compounds (VOCs) and other harmful chemicals, promoting a safer work environment and reducing the carbon footprint of label printing operations.

Versatility and Adaptability

UV curing can be applied to a diverse array of label substrates, including heat-sensitive materials, without causing damage. This versatility allows for the creation of labels on various surfaces while maintaining optimal adhesion and performance. UV curing systems can be seamlessly integrated with flexographic, offset, and digital inkjet printing processes, enhancing the capabilities of each method and enabling the production of high-quality labels tailored to specific needs.

Benefits of UV Curing Systems in Label Printing

Label Converting

UV curing plays a crucial role in label converting, where manufacturers create decorative, durable, and functional product labels. It facilitates printing on a wide range of materials and enables inline embellishments, high-gloss finishes, and special effects, making labels stand out and enhancing their appeal.

Digital Inkjet Label Presses

In digital inkjet label printing, UV curing is essential for producing short runs, variable data, and jobs with high precision. It allows for partial curing of under white layers, pinning of colors, and final curing of fully printed labels, ensuring quality and efficiency in digital production environments.

Future Trends

The label printing industry continues to evolve, with ongoing innovations in UV curing technology. Advances in LED technology, more efficient photoinitiators, and smarter curing systems are expected to further enhance productivity, quality, and sustainability. Additionally, the integration of UV curing with emerging printing technologies and substrates will open new possibilities for creative and functional label designs.

UV curing has transformed the label printing industry by offering faster, more efficient, and environmentally friendly solutions. Its ability to enhance print quality, increase productivity, and support sustainable practices makes it an invaluable technology for label manufacturers. As the industry progresses, UV curing will remain at the forefront of innovation, driving the production of labels that not only meet but exceed the demands of consumers and businesses alike.

Contact IUV LED UV Experts