Modern print shops face a constant battle between increasing production capacity and limited floor space. As demand for high-quality labels and flexible packaging grows, narrow-web converters often find themselves squeezed. Traditional mercury arc lamps, while effective for decades, present significant hurdles in these tight environments. They require bulky cooling systems, large power cabinets, and massive exhaust ducting to manage ozone and heat.

The industry has shifted toward LED UV technology to solve these spatial challenges. This review examines how LED UV systems perform when integrated into compact press configurations, specifically focusing on flexographic, offset, and narrow-web label printing.

The Spatial Physics of LED UV vs. Mercury Arc

Traditional UV curing relies on medium-pressure mercury vapor lamps. These units are physically large because they require mechanical shutters to protect the substrate when the press stops. Furthermore, the heat generated by mercury bulbs is intense. To prevent the press frame from warping or the substrate from melting, engineers must install large blowers and air-handling systems.

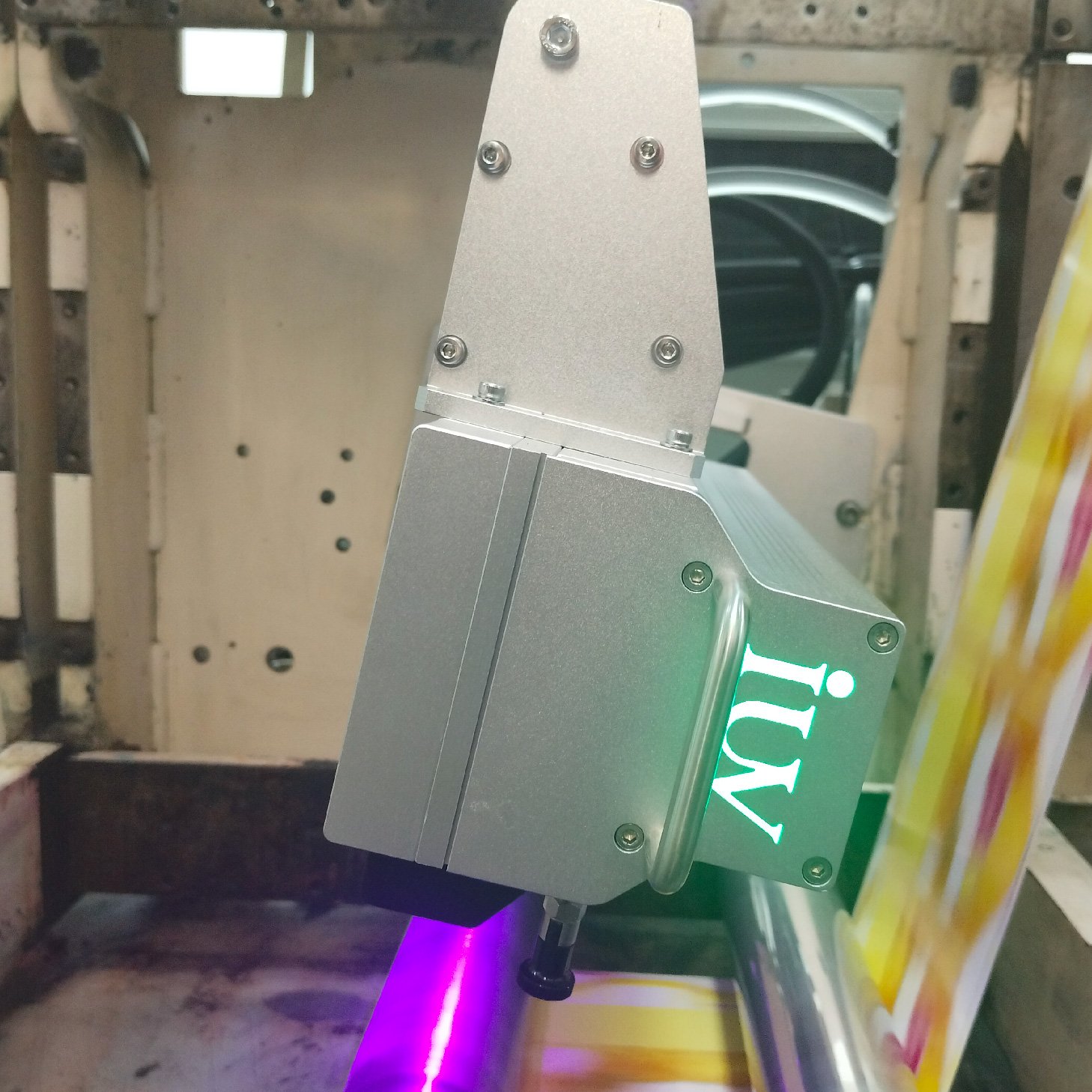

LED UV units eliminate these requirements. A typical LED lamp head is a fraction of the size of a mercury housing. There are no moving shutters because LEDs turn on and off instantly. In a space-constrained press, this reduction in physical volume allows for more curing stations within the same footprint. For a narrow-web press, this might mean the difference between running five colors or eight colors in a fixed modular length.

Performance in Narrow-Web Label Printing

Label printing often involves heat-sensitive substrates like thin films and shrink sleeves. In a cramped press configuration, heat buildup is a major risk. Traditional lamps radiate vast amounts of infrared (IR) energy. When space is limited, this IR heat stays trapped near the web path.

LED UV technology emits light in a narrow band, usually 395nm or 385nm. It produces almost zero IR radiation. In our review of compact configurations, LED systems maintained a stable substrate temperature even at high speeds. This stability allows converters to use thinner, lower-cost films without fear of stretching or distorting the material. The compact nature of the LED heads also allows them to be placed closer to the nip, improving the overall efficiency of the curing process.

Flexographic Printing and Ink Layer Curing

Flexo printing requires consistent energy delivery to cure thick ink layers and coatings. In space-constrained setups, the distance between the lamp and the substrate is often fixed and quite short. LED UV systems excel here because of their high peak irradiance.

Mercury lamps lose effectiveness quickly as the distance from the bulb increases, but they also require a certain “focus” distance to work correctly. LED arrays provide a more uniform distribution of energy across the entire web width. Our technical analysis shows that LED UV provides deeper polymerization in flexo inks, especially with high-pigment loads like opaque whites and dense blacks. This happens because the 395nm wavelength penetrates deeper into the ink film than the shorter wavelengths predominant in mercury systems.

Retrofitting Offset Presses with Compact LED Units

Sheet-fed and web-offset presses are notoriously difficult to retrofit due to the tight clearances between printing units. Engineers often struggle to find “real estate” for traditional UV lamps. LED UV has revolutionized this segment.

Small-format LED lamps can fit into the delivery section or between units where a mercury lamp simply would not fit. Because LED systems do not produce ozone, there is no need to cut holes in the building for exhaust ducting. This makes the installation process faster and less invasive. For an offset printer operating in an urban environment with strict space and emission regulations, LED UV is often the only viable path to UV production.

Energy Density and Throughput Efficiency

A common concern in space-constrained environments is whether a smaller lamp can keep up with high-speed production. The performance data suggests that modern LED UV systems actually exceed mercury lamps in energy density.

While a mercury lamp might be rated at 400 or 600 Watts per inch, much of that energy is wasted as heat and non-useful light. An LED system converts a much higher percentage of electrical input into useful UV output. In a narrow-web configuration running at 200 meters per minute, a compact LED array provides sufficient “dose” (total energy over time) and “irradiance” (peak intensity) to ensure a full cure. This allows for faster run speeds on machines that were previously limited by their curing capacity.

Thermal Management in Tight Quarters

Even though LEDs are “cool” compared to mercury, they still generate heat at the back of the diode array. Effective thermal management is vital in cramped press designs. There are two primary methods: air-cooling and water-cooling.

In extremely tight configurations, water-cooled LED systems are preferred. Water-cooled units are smaller than air-cooled units because they do not need large internal fans or heat sinks. The heat is moved away from the press via a closed-loop chiller located elsewhere in the facility. This keeps the press area quiet and cool. Our review indicates that water-cooled LED units offer the highest reliability in high-speed, 24/7 label production environments where airflow might be restricted by other machine components.

Maintenance and Operational Longevity

In a space-constrained shop, accessing equipment for maintenance is a nightmare. Changing a mercury bulb often involves dismantling parts of the press frame or ducting. Mercury bulbs have a lifespan of roughly 1,000 to 2,000 hours. They also degrade gradually, making cure quality unpredictable.

LED modules are rated for 20,000 to 30,000 hours of operation. They do not require daily cleaning of reflectors or shutters. For a professional engineer, the “fit and forget” nature of LED UV is a massive advantage. In a compact press layout, reducing the frequency of maintenance translates directly to higher OEE (Overall Equipment Effectiveness). There is no “warm-up” or “cool-down” period, meaning the press can start and stop instantly without wasting substrate.

Ink Chemistry and Photoinitiator Synergy

The performance of LED UV in compact configurations is tied to the evolution of UV chemistry. Ten years ago, LED-curable inks were expensive and limited. Today, ink manufacturers have optimized photoinitiators to react specifically to the narrow output of LED chips.

In narrow-web and flexo applications, these “LED-ready” inks offer better adhesion and scratch resistance. Because the curing happens almost instantaneously at the point of light exposure, there is less time for the ink to bleed or gain dot. This results in sharper imagery and more vibrant colors, which is a key requirement for high-end cosmetic and pharmaceutical labels.

Economic Impact of the Small Footprint

The ROI of switching to LED UV in a space-constrained environment goes beyond electricity savings. By shrinking the curing section of a press, companies can fit more equipment into their existing floor space.

If a printer can fit three LED-equipped presses in the space previously occupied by two mercury-equipped presses, their revenue potential per square foot increases by 50%. Additionally, the elimination of high-voltage power supplies and massive air-handling units reduces the insurance premiums and fire risks associated with traditional UV printing.

Summary of Performance Metrics

When evaluating LED UV performance in space-constrained press configurations, several metrics stand out:

- Instant On/Off: Eliminates the need for mechanical shutters and reduces the physical footprint of the lamp housing.

- Low Thermal Profile: Allows for the processing of thin, heat-sensitive films in tight web paths without distortion.

- High Irradiance: Provides faster curing speeds for flexo and offset inks despite the small size of the light source.

- Zero Ozone: Removes the need for bulky exhaust systems, simplifying the press layout.

- Durable Output: Thousands of hours of consistent UV intensity without the degradation seen in mercury bulbs.

The integration of LED UV technology represents a fundamental shift in how printing presses are designed. No longer are engineers forced to build machines around the limitations of a bulky, hot light source. Instead, the curing system can be tucked into the natural flow of the press, maximizing both space and productivity. For the narrow-web, label, and offset sectors, LED UV is not just an alternative; it is the superior choice for modern, space-efficient manufacturing.