The transition from traditional Mercury arc lamps to LED UV curing represents a fundamental shift in printing physics. For engineers and press operators, this change is more than a simple equipment upgrade. It involves rethinking the relationship between ink chemistry, substrate sensitivity, and energy delivery.

In narrow web and label printing, the demand for low-tack and specialty inks is rising. These materials offer unique aesthetic and functional properties but present distinct curing challenges. Understanding the mechanics of LED UV ensures consistent production speeds and high-quality output across flexo and offset platforms.

The Physics of LED UV Curing

LED UV systems emit light in a narrow spectral band, typically centered at 365nm, 385nm, or 395nm. Unlike Mercury lamps, which provide a broad spectrum of UV-A, UV-B, and UV-C radiation, LEDs are monochromatic.

This narrow output requires precise matching between the light source and the photoinitiators in the ink. If the ink chemistry does not align with the 395nm peak, the curing process will fail. Engineers must focus on two primary metrics: irradiance and energy density.

Irradiance, measured in $W/cm^2$, is the peak intensity of the light hitting the surface. It determines the ability of the UV rays to penetrate thick ink layers or opaque whites. Energy density, or dosage, is measured in $mJ/cm^2$. It represents the total amount of light energy delivered over a specific period. Both are critical for ensuring a full through-cure in high-speed narrow web applications.

Challenges with Low-Tack Inks

Low-tack inks are often used to prevent picking on delicate substrates or to achieve specific release properties in specialty labels. However, these formulations are highly susceptible to oxygen inhibition.

Oxygen at the ink surface reacts with free radicals faster than the photoinitiators can. This creates a tacky, uncured surface layer, even if the bottom of the ink film is solid. Mercury lamps mitigate this with high-energy UV-C light, which provides excellent surface cure. LED systems lack UV-C.

To overcome this in an LED environment, engineers must utilize high-irradiance lamps. Increasing the intensity allows the free radicals to overwhelm the oxygen molecules. Additionally, using nitrogen inertion on the press can physically displace oxygen, though this is usually reserved for high-end food packaging applications.

Curing Specialty Inks: Metallics and Opaque Whites

Specialty inks like metallics, fluorescents, and heavy opaques present a barrier to UV penetration. In flexo printing, opaque white is often the first down color. It must be perfectly cured to provide a stable foundation for CMYK layers.

Metallic pigments act like tiny mirrors. They reflect UV radiation away from the photoinitiators. Opaque whites contain titanium dioxide, which absorbs UV light in the same range that most photoinitiators require.

LED UV is actually superior for these applications because the 395nm wavelength penetrates deeper into thick or pigmented films than shorter wavelengths. By using a high-output LED array, you can achieve deep curing through 5-6 microns of dense ink at speeds exceeding 150 meters per minute.

Optimization for Flexo and Narrow Web

Flexo printing relies on consistent ink transfer from the anilox roll. When moving to LED, the heat reduction is the most immediate benefit. Traditional lamps generate significant infrared heat, which can stretch thin films like PE or PP.

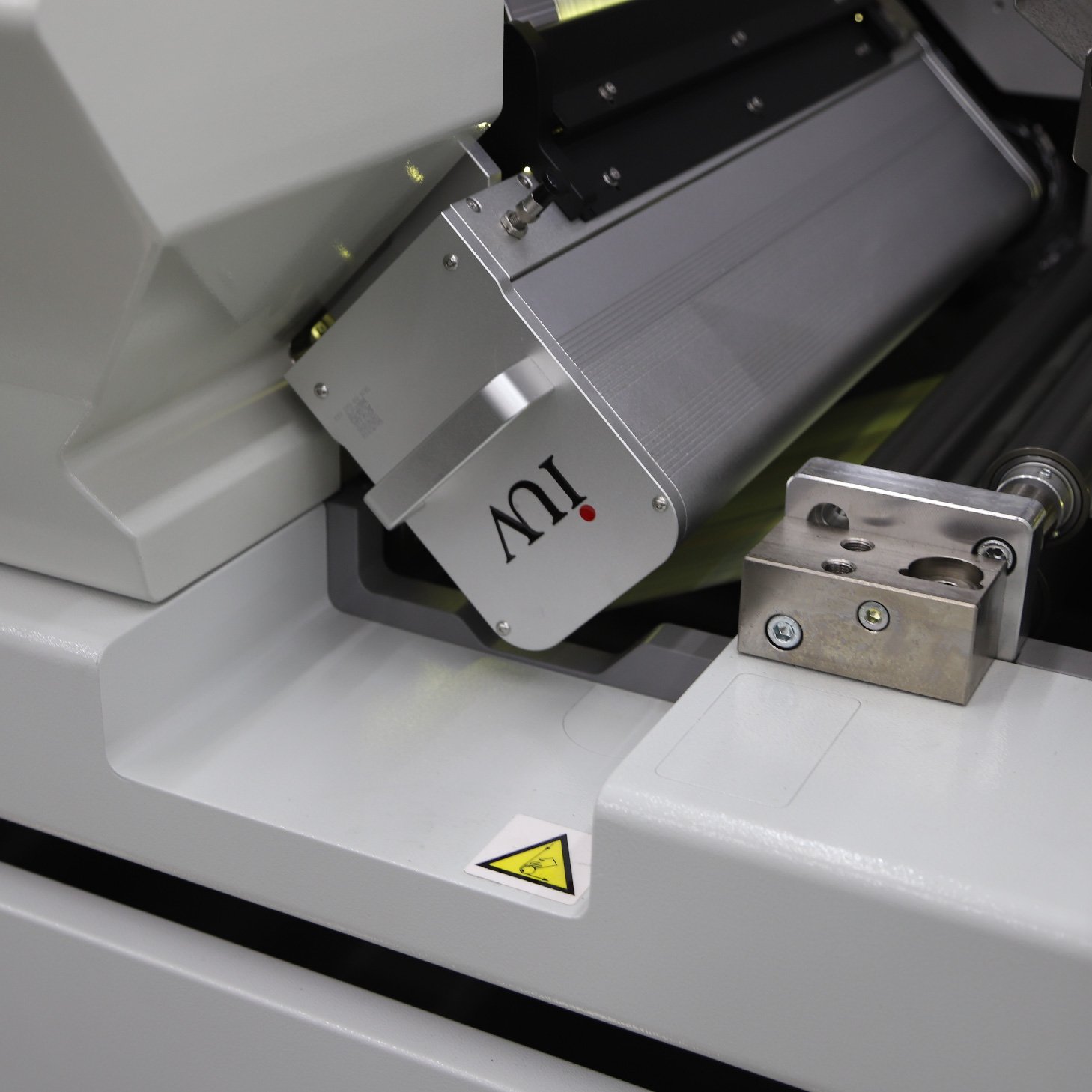

LED arrays are “cold” light sources. This stability allows for tighter registration on heat-sensitive materials. To optimize the setup, the distance between the LED head and the substrate must be minimized. Most systems are designed to operate at a 10mm to 20mm gap. Increasing this distance even slightly causes a massive drop in irradiance due to the beam’s divergence.

Integrating LED in Offset Printing

Offset printing involves a much thinner ink film than flexo, but the ink-water balance adds complexity. LED UV curing in offset prevents “dry-back,” a phenomenon where ink loses its gloss as it sinks into the paper.

For retrofitting sheet-fed or narrow web offset presses, the placement of the LED lamp is vital. Usually, one lamp after the last printing unit is sufficient for standard CMYK. However, if you are running specialty coatings or double-hit whites, inter-deck curing is necessary.

The lack of heat from LEDs prevents the pile from sticking in the delivery. It also eliminates the need for anti-set-off powder, which keeps the pressroom cleaner and improves the lamination quality of the finished labels.

Managing Heat and Thermal Load

While LED UV does not emit infrared heat toward the substrate, the chips themselves generate significant heat internally. Effective thermal management is the difference between a system that lasts 20,000 hours and one that fails in six months.

Most high-speed narrow web presses use water-cooled LED systems. A chiller circulates coolant through the back of the LED array to maintain a constant junction temperature. If the temperature fluctuates, the spectral output of the LEDs can shift. This shift may lead to inconsistent curing results across a long production run.

Engineers should monitor chiller performance as part of daily maintenance. A slight increase in operating temperature can reduce the lifespan of the LED diodes significantly.

Substrate Versatility and Adhesion

One of the greatest advantages of LED UV is the ability to print on a wider range of substrates. Heat-sensitive shrink sleeves and ultra-thin clear films are difficult to process with Mercury lamps. LED makes these materials standard.

However, adhesion must be tested. Since LED inks contain different photoinitiators and resins, their surface tension and bonding characteristics change. Corona treatment is still recommended for non-porous films to increase surface energy. Always perform a tape test or a dyne level test immediately after curing to ensure the low-tack ink has bonded correctly to the specialty substrate.

Measuring and Maintaining the System

You cannot manage what you do not measure. In a Mercury system, bulbs degrade predictably. LEDs degrade very slowly, but they can be affected by dust, ink mist, or cooling failures.

Using a UV radiometer specifically calibrated for LED wavelengths is mandatory. Standard radiometers designed for Mercury lamps will give false readings. Regular mapping of the irradiance across the web width ensures that the “outboard” and “inboard” edges of the labels are receiving the same energy as the center.

Keep the protective glass windows of the LED heads clean. Even a fine mist of specialty ink can block 20% of the UV output, leading to “ghosting” or uncured spots in the middle of a high-speed run.

The Economic and Environmental Impact

Beyond the technical specs, the transition to LED UV for specialty inks offers a significant reduction in operational costs. LED systems consume up to 70% less electricity than Mercury systems. There is no warm-up or cool-down time, which increases press uptime.

From a safety perspective, LEDs eliminate ozone production and the need for mercury disposal. This makes the pressroom a better environment for operators and simplifies compliance with environmental regulations.

Future-Proofing the Curing Process

The shift toward LED UV is permanent. As ink manufacturers continue to refine low-tack and specialty formulations, the chemistry will become even more efficient. Engineers should focus on modular LED systems that allow for future intensity upgrades.

By mastering the balance of wavelength, irradiance, and ink chemistry, printing houses can tackle the most complex label designs with confidence. Whether it is a high-build varnish or a low-migration ink for food labels, LED UV provides the precision required for modern narrow web production.