The Evolution of Printing with LED Curing Systems

The printing industry continuously seeks innovative solutions that boost efficiency, improve quality, and reduce environmental impact. Among these advancements, LED curing systems stand out as a game-changer. Their role in achieving zero volatile organic compounds (VOC) printing opens new possibilities for sustainable manufacturing practices. This shift aligns with the increasing demand for eco-friendly production while maintaining high standards of color fidelity and print durability.

Understanding LED Curing Technology in Printing

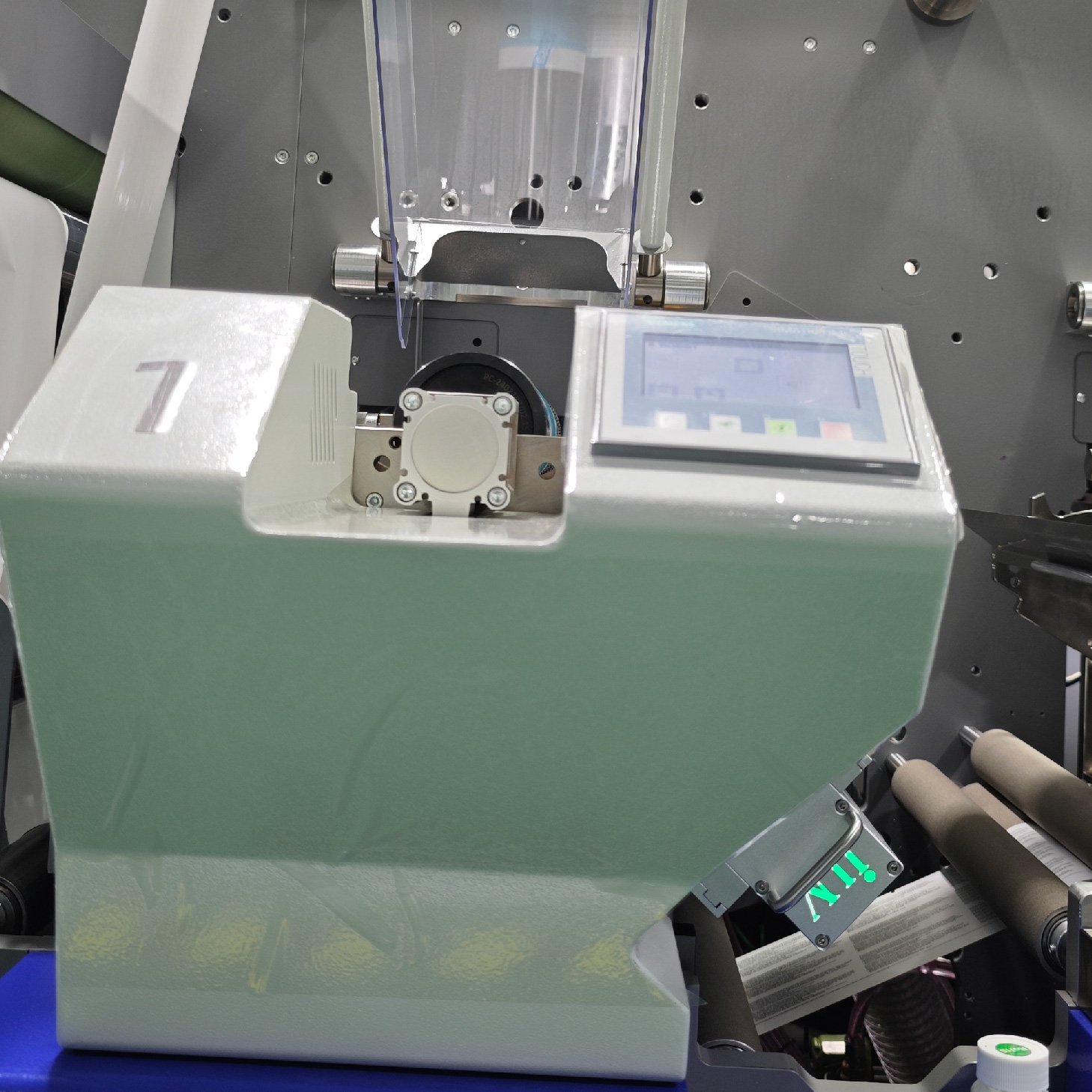

LED curing technology employs ultraviolet (UV) light-emitting diodes to rapidly initiate photopolymerization of inks and coatings. Unlike traditional UV lamps, LED systems consume less energy, generate less heat, and have longer operational lifespans. The precision and controllability of LED UV curing allow for instant curing of inks without prolonged exposure, resulting in faster production times and reduced waste.

LED UV systems are compatible with a wide range of printing processes, including flexography, letterpress, and narrow-bandwidth UV inks. Their ability to cure instantly means less ink bleed, sharper images, and vibrant colors, which are essential in high-quality label printing and other specialty applications.

Significance for Screen, Flexo, and Letterpress Printing

In label and screen printing, accuracy and consistency are vital. LED UV curing enhances these aspects by offering uniform light distribution and quick curing times. This leads to better registration and sharper images, especially when printing intricate labels and multicolor designs.

For flexographic and letterpress printers, LED curing significantly shortens drying times. Traditional solvent or heat-based curing methods can cause delays and affect the overall workflow. LED systems eliminate these bottlenecks, allowing for high-speed production with fewer interruptions.

The Impact on Narrow-Band and Finishing Processes

Narrow-width printing, often used in specialty labels and fine art prints, demands precise registration and impeccable detail. LED UV curing supports these needs by providing consistent curing across narrow web widths, minimizing distortions and ensuring color accuracy.

Moreover, LED curing facilitates advanced finishing techniques such as embossing, foil stamping, and lamination. Since the curing process is instant, it integrates seamlessly into complex workflows, improving overall productivity and output quality.

Reducing VOCs with LED UV Curing Systems

Traditional solvent-based inks release VOCs during drying, contributing to air pollution and health hazards. UV curing inks, particularly those cured with LED technology, are free from solvents, significantly reducing VOC emissions. This means cleaner production environments and compliance with strict environmental regulations.

Implementing LED UV curing supports companies in achieving zero VOC printing. It aligns with sustainability goals by decreasing toxic fumes and waste, and by reducing energy consumption associated with curing processes.

Benefits for Tag, Flexo, and Circumferential Printing

Tag printing, often used for product packaging and branding, demands impeccable quality and durability. LED UV curing ensures fast production and high resistance to wear and environmental factors, vital for labels exposed to outdoor conditions.

In flexographic and circumferential printing, LED systems enable high-speed runs with minimal downtime. Their low heat output preserves sensitive substrates, preventing warping or distortion. As a result, manufacturers can run more jobs efficiently, with less waste and rework.

Enhancing Eco-Friendly Practices in the Printing Industry

Adoption of LED curing systems signifies a broader shift toward greener printing practices. The technology’s low energy consumption, absence of hazardous chemicals, and ability to produce zero VOC prints make it a strategic choice for eco-conscious businesses.

By reducing reliance on solvents and volatile compounds, printers can reach sustainability targets and satisfy customer demands for environmentally responsible packaging and labeling solutions.

Future Trends in LED UV Curing for Printing

The potential of LED UV curing continues to expand with technological improvements. Advances include broader wavelength options, higher power outputs, and integration with digital workflows. These innovations will further enhance print quality, speed, and environmental performance.

Emerging applications involve hybrid systems that combine LED UV curing with digital printing technologies. This synergy enables highly customizable, fast-turnaround jobs with minimal environmental impact and maximum quality.

Conclusion

LED curing systems are transforming the landscape of label, flexo, and narrow-bandwidth printing. Their ability to deliver high-quality, durable, and eco-friendly prints aligns perfectly with the industry’s move toward sustainability. By eliminating VOCs and reducing energy consumption, LED UV technologies set new standards for responsible printing practices.

As the industry advances, embracing LED curing will not only improve operational efficiency but also demonstrate a genuine commitment to environmental stewardship. The future of zero VOC printing is illuminated – literally and figuratively – by LED UV curing systems.