-

UV ink, also known as ultraviolet ink, is a type of ink that cures and dries when exposed to ultraviolet (UV) light.

-

This process is known as photopolymerization, where the ink reacts with the UV light to form a solid, durable layer on the substrate.

-

UV ink is known for its exceptional durability, scratch resistance, and high-quality print output, making it a popular choice for a wide range of applications, including commercial printing, packaging, and industrial manufacturing.

-

One of the key advantages of UV ink is its ability to produce vibrant, high-definition colors that maintain their vibrancy over time. The curing process also allows for immediate handling and processing of the printed materials, enhancing efficiency and productivity in the printing workflow.

-

UV LED ink, on the other hand, is a newer and more energy-efficient alternative to traditional UV ink. Instead of relying on traditional UV lamps, UV LED ink cures when exposed to light-emitting diode (LED) technology. This innovative approach offers several benefits, including faster curing times, reduced energy consumption, and a more compact and portable printing setup.

-

UV LED ink is particularly well-suited for applications where precise control and consistent curing are essential, such as digital printing, label printing, and industrial manufacturing. The LED-based curing process allows for more targeted and efficient ink activation, resulting in improved print quality, reduced waste, and increased productivity.

-

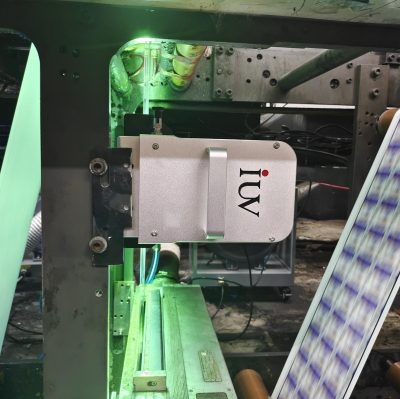

UV Ink Curing

UV ink requires exposure to high-intensity ultraviolet lamps to initiate the photopolymerization process, which quickly transforms the liquid ink into a solid, durable layer on the substrate.

-

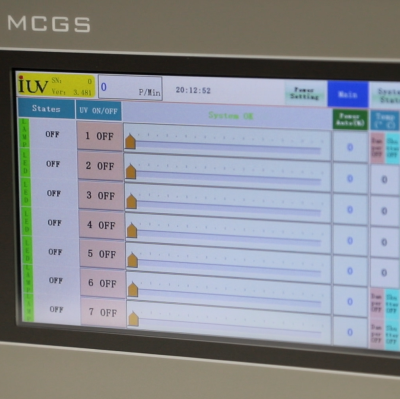

UV LED Ink Curing

UV LED ink, on the other hand, utilizes light-emitting diodes (LEDs) to cure the ink. This process is more targeted and efficient, allowing for faster curing times and reduced energy consumption compared to traditional UV lamps.

-

UV Ink Composition

UV ink typically contains a combination of monomers, oligomers, and photoinitiators, which react when exposed to UV light to form a solid, durable layer.

The specific formulation can vary depending on the application and desired properties, such as flexibility, adhesion, or chemical resistance.

-

UV LED Ink Composition

UV LED ink is formulated to be more responsive to the narrow wavelength range emitted by LED light sources.

Often requiring different photoinitiators and other additives compared to traditional UV ink.

This specialized composition allows for more efficient and targeted curing with LED technology.

-

UV Ink Print Quality

UV ink is known for producing high-definition, vibrant, and color-accurate prints with excellent image resolution and detail.

The curing process helps to maintain the integrity of the ink layer, resulting in a smooth, glossy finish.

-

UV LED Ink Print Quality

UV LED ink also delivers exceptional print quality, with the added benefit of more consistent curing and reduced risk of over-curing.

The targeted curing process allows for precise control over ink laydown, leading to sharper, more detailed prints.

-

Improved Dot Gain Control

The precise curing of UV LED ink can also result in better dot gain control, meaning the printed dots maintain their intended size and shape more accurately. Leading to higher-quality text, graphics, and images.

-

Cost Considerations

-

While UV ink may have a lower upfront cost, the higher energy consumption and maintenance requirements of traditional UV lamps can result in higher operating costs over time.

-

UV LED ink, on the other hand, the unit price is more expensive, but the dosage is lower, making the total cost similar.

-

And UV LED ink offers significant savings in energy usage and reduced maintenance, making it a more cost-effective solution in the long run.

-

Efficiency and Productivity

-

The faster curing times and more targeted curing process of UV LED ink can also contribute to improved efficiency and productivity in printing operations.

-

This can lead to reduced waste, faster turnaround times, and increased output capacity compared to traditional UV printing setups.

-

Environmental Considerations

-

In addition to cost savings, the energy-efficient nature of UV LED ink also makes it a more environmentally friendly choice.

-

As reduced carbon footprint and lower energy consumption compared to conventional UV printing methods.

-

Assess Your Printing Needs

The first step in choosing the right ink is to carefully evaluate your specific printing requirements. Such as the type of substrates you’ll be printing on, the desired print quality, and any unique performance characteristics you need, like flexibility, chemical resistance, or low-odor properties.

-

Consider Your Printing Environment

The physical constraints and infrastructure of your printing environment can also play a role in determining the most suitable ink. Factors like available space, power requirements, and ventilation needs may influence whether UV or UV LED ink is the better fit.

-

Evaluate the Tradeoffs

Once you’ve identified your key requirements, carefully weigh the benefits and tradeoffs of each ink type, including factors like print quality, curing speed, cost, and environmental impact. This will help you make an informed decision that aligns with your specific printing needs and business objectives.