-

UV Light Exposure

UV ink drying employs high-intensity mercury vapor lamps that emit a wide spectrum of ultraviolet light, catalyzing a photochemical reaction for rapid curing.

-

Photochemical Reaction

The UV light triggers a photochemical reaction that causes the ink’s monomers and oligomers to cross-link and solidify, resulting in a durable, high-quality print.

-

Instant Curing

The UV curing process is nearly instantaneous, allowing for immediate handling and post-processing of the printed materials, improving workflow efficiency.

-

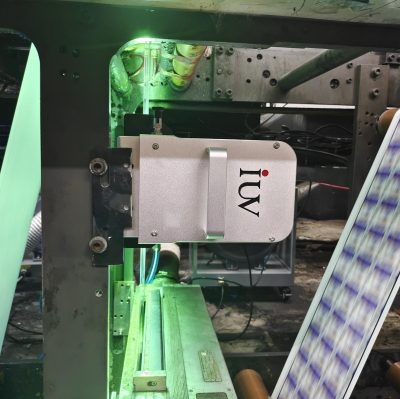

Energy-Efficient LED

LED-UV ink drying harnesses the power of light-emitting diodes to initiate the curing process, offering a more energy-efficient alternative to traditional mercury-based UV lamps.

-

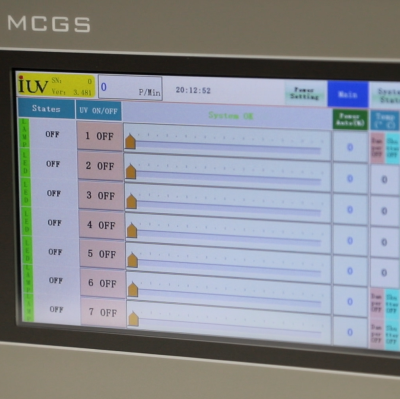

Controlled Curing

LED UV curing technology ensures safety and reliability, with no solvent emissions, non-flammability, and minimal environmental impact. This makes it suitable for packaging prints with stringent hygienic requirements, such as food, beverages, tobacco, alcohol, and medicines.

-

Longer Lifespan

LED-UV systems have a significantly longer lifespan compared to mercury-based UV lamps, resulting in lower maintenance costs and more reliable printing operations.

-

Curing Mechanics

While both UV and LED-UV inks use ultraviolet light to initiate the curing process, the LED-UV approach offers a more targeted and controlled application of the light energy.

-

Energy Efficiency

LED-UV systems are significantly more energy-efficient than traditional mercury-based UV lamps, reducing operational costs and environmental impact.

-

Thermal Impact

The cooler curing method of LED-UV inks minimizes heat exposure, enabling the use of a wider range of heat-sensitive printing materials.

Expanding the Possibilities of Printing

The choice between UV and LED-UV ink drying can have a significant impact on the range of materials you can print on, as well as the overall look and durability of the printed product. LED-UV’s cooler curing method expands the compatibility with heat-sensitive substrates, opening up new possibilities for creative and diverse printing applications.

-

Energy Efficiency

LED-UV systems consume significantly less energy compared to traditional UV lamps, resulting in lower operational costs and a smaller carbon footprint.

-

Reduced Waste

The targeted and controlled curing of LED-UV inks minimizes material waste, contributing to a more sustainable printing process.

-

Safer Chemicals

LED-UV inks often utilize more environmentally friendly and less hazardous chemical components, promoting a healthier work environment.

-

Understand the Differences

Recognize the key distinctions between UV and LED-UV ink drying processes to make an informed decision for your printing needs.

-

Evaluate Your Requirements

Consider the range of materials you need to print on, as well as your operational efficiency and environmental goals, to determine the best-suited technology.

-

Embrace the Future

Adopt the cutting-edge LED-UV technology to stay at the forefront of printing innovation and deliver high-quality, sustainable printing solutions.

-

Curing Speed Comparison

The curing speed of LED-UV inks is generally faster than that of traditional UV inks, thanks to the targeted and controlled application of the LED light energy. This rapid curing allows for immediate handling and post-processing of the printed materials, improving overall workflow efficiency.

-

Material Compatibility

One of the key advantages of LED-UV inks is their compatibility with a wider range of printing substrates, including heat-sensitive materials such as plastics, foils, and thin films. The cooler curing process of LED-UV technology opens up new possibilities for creative and diverse printing applications.

-

Environmental Benefits