The label printing industry thrives on precision, speed, and adaptability. As demand grows for high-quality, durable labels across sectors like food packaging, pharmaceuticals, and cosmetics, UV curing systems have emerged as a game-changing technology. By integrating LED UV curing into flexographic, offset, or narrow-web printing workflows, manufacturers achieve unmatched efficiency and performance. Below are the key advantages of adopting UV curing systems in label production.

1. Instant Curing for Faster Turnarounds

Traditional solvent- or water-based inks require extended drying times, creating bottlenecks in high-volume label printing. UV curing systems eliminate this delay by hardening inks, coatings, and adhesives immediately under UV light. This instant curing allows presses to run at full speed without compromising quality. For time-sensitive orders—such as limited-edition beverage labels or seasonal promotions—this technology ensures rapid production cycles.

2. Superior Print Quality & Durability

UV-cured inks retain sharpness and vibrancy even on challenging substrates like metallic films, textured papers, or synthetic materials. Unlike conventional inks, which can spread or absorb into porous surfaces, UV formulations stay precisely where they’re printed. This results in:

- Crisp text and fine lines for barcodes or small fonts.

- High opacity for vibrant whites and metallics.

- Scratch- and chemical-resistant finishes.

Labels withstand abrasion during transportation, moisture in cold storage, or exposure to oils in kitchen environments, ensuring legibility throughout their lifecycle.

3. Energy Efficiency & Cost Savings

LED UV curing systems consume up to 70% less energy than mercury-vapor lamps. They generate minimal heat, reducing the need for air conditioning in pressrooms. Additionally:

- No solvents mean lower VOC emissions and compliance with environmental regulations.

- Reduced ink waste due to precise curing and minimal dot gain.

- Longer lamp lifespan (20,000+ hours) cuts maintenance costs.

For narrow-web printers operating 24/7, these savings directly improve profit margins.

4. Versatility Across Printing Methods

UV curing complements multiple label printing processes:

- Flexographic Printing: Ideal for flexible packaging and pressure-sensitive labels. UV curing prevents ink smudging on fast-moving webs.

- Offset Printing: Delivers sharp detail for premium wine or cosmetic labels.

- Hybrid Systems: Combines flexo, digital, and screen printing for complex designs.

The technology also supports specialty coatings like soft-touch finishes, gloss/matte effects, or security features (e.g., holographic overlays).

5. Eco-Friendly Production

Sustainability is a priority for brands and consumers. UV curing aligns with green initiatives by:

- Eliminating solvent emissions and hazardous waste.

- Enabling recyclable label materials (since UV inks don’t contaminate recycling streams).

- Reducing energy consumption compared to thermal drying systems.

Printers can market their services as eco-conscious, appealing to clients seeking sustainable packaging solutions.

6. Enhanced Adhesion on Non-Porous Substrates

Labels increasingly use synthetic materials like PET, PP, or PE films for waterproofing and durability. These non-porous surfaces challenge traditional inks, which struggle to adhere without primers. UV-cured inks polymerize instantly upon exposure to light, forming a strong bond with plastics, foils, and other tricky substrates. This eliminates delamination risks in humid or wet conditions.

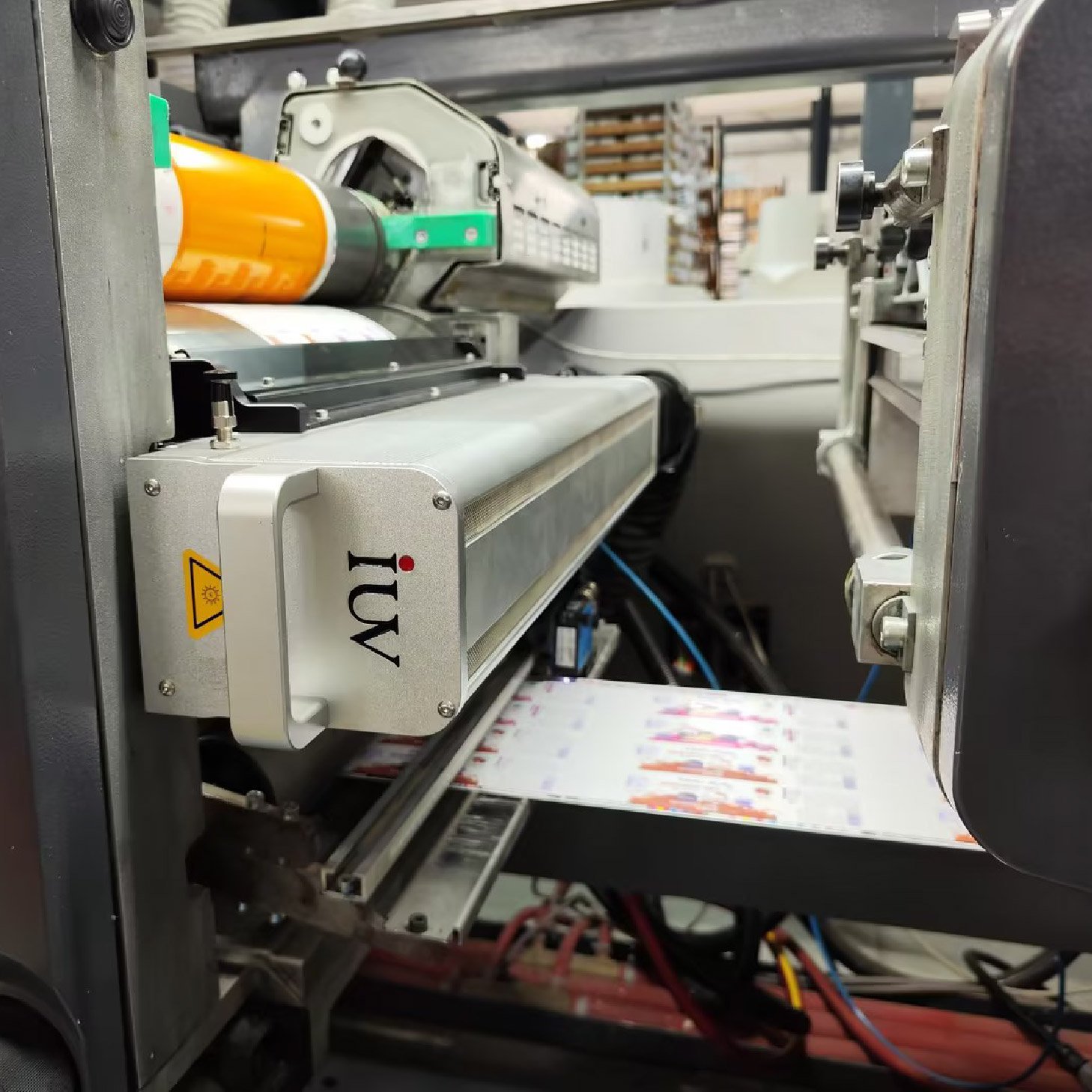

7. Compact Design for Space-Constrained Facilities

LED UV lamps are smaller and lighter than conventional curing units. Narrow-web printers, often operating in compact facilities, benefit from easy integration into existing presses without major retrofitting. The modular design also allows targeted curing for specific print zones, optimizing energy use.

8. Reduced Downtime & Higher Productivity

Mercury lamps require warm-up periods and frequent replacements, halting production. LED UV systems activate instantly and maintain consistent output throughout their lifespan. With no cooling delays between jobs, printers maximize uptime—critical for meeting tight deadlines in industries like pharmaceuticals, where label changes are frequent.

9. Compatibility with Digital Hybrid Presses

As digital label printing grows, hybrid systems combining inkjet and flexo stations gain popularity. UV curing ensures digital inks cure rapidly, enabling inline finishing (e.g., varnishing, die-cutting) in a single pass. This workflow suits short runs with variable data, such as personalized cosmetics or limited-batch craft beer labels.

10. Future-Proofing for Regulatory Changes

Global regulations increasingly restrict solvent use and VOC emissions. UV curing systems future-proof printing operations by adhering to strict environmental standards. Early adopters avoid costly transitions later while positioning themselves as innovators in a competitive market.

Conclusion UV curing systems redefine efficiency and quality in label printing. From accelerating production speeds to enabling eco-friendly practices, this technology addresses the core challenges faced by flexographic, offset, and narrow-web printers. Brands demanding durable, visually striking labels will gravitate toward partners equipped with UV capabilities. For printers, investing in LED UV curing isn’t just an upgrade—it’s a strategic move to lead in a fast-evolving industry.