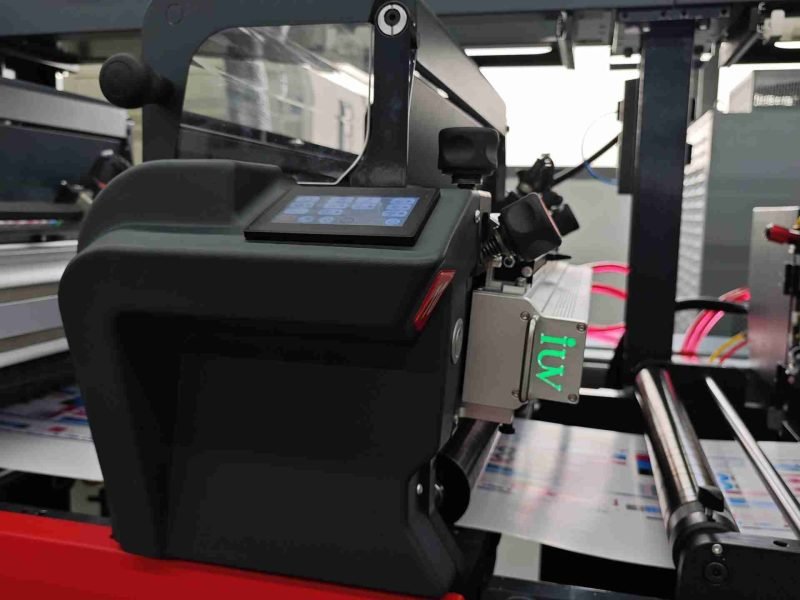

In the fast-evolving landscape of label and packaging printing, integrating cutting-edge technology is essential for staying competitive. This case study explores the successful installation of IUV’s LED UV curing system on a new Omet Kflex flexographic printing press, highlighting the process, benefits, and outcomes for our client.

Background

Our client, a leading label printing company, sought to enhance their production capabilities by investing in a new Omet Kflex flexographic printing press. They aimed to improve print quality, increase production efficiency, and reduce environmental impact. The decision was made to integrate IUV’s advanced LED UV curing system to achieve these goals.

The IUV LED UV Curing System and Omet Kflex Press

Omet Kflex Flexographic Press

The Omet Kflex is a modular platform press designed for versatility and efficiency:

- Substrate Flexibility: Handles materials from 12 microns up to aluminum lidding and light cartonboard.

- High Speed: Maximum print speed of 200m/min (656ft/min).

- Switch Technology: Allows rapid exchange of printing and converting units for quick reconfiguration.

- Dual UV/LED-UV Paths: Provides flexibility in coating and printing applications.

IUV LED UV Curing System

IUV’s LED UV curing system represents a significant advancement in curing technology, offering:

- Energy Efficiency: Consumes significantly less power than traditional UV curing methods.

- Instant Curing: Provides immediate curing upon exposure to UV light, preventing smudging and ink migration.

- Long Lifespan: LED lamps last over 30,000 hours, reducing replacement frequency.

- Environmental Friendliness: No mercury content and minimal VOC emissions.

Installation Process

Pre-Installation Preparation

- Site Assessment: Ensured the installation area was clean, well-ventilated, and had appropriate power supply.

- Equipment Inspection: Verified all components were in good condition and compatible with the Omet Kflex press.

System Integration

- Mounting the Curing Units: Installed IUV’s LED UV curing units at strategic positions on the Omet Kflex press.

- Electrical Connections: Connected the system to the press’s power supply following safety protocols.

- Control System Integration: Integrated the LED UV system’s controls with the Omet Kflex’s operating interface for seamless operation.

Post-Installation Checks

- Functionality Testing: Conducted tests to ensure each LED UV unit was functioning correctly.

- Safety Checks: Inspected for any potential hazards, ensuring all connections were secure.

Implementation and Training

- Operator Training: Provided comprehensive training on the operation, maintenance, and safety procedures of the new system.

- Technical Support: IUV’s team offered ongoing support to ensure smooth transition and address any concerns during initial operation.

Results and Benefits

Enhanced Print Quality

- Sharper Details: The precise control of the LED UV curing system resulted in clearer text and finer details.

- Vibrant Colors: Improved ink adhesion led to more vivid and consistent colors across various substrates.

Increased Production Efficiency

- Faster Curing: The rapid curing capability allowed for higher production speeds, reducing lead times by approximately 25%.

- Reduced Downtime: The instant on/off feature of LED UV systems minimized setup and changeover times.

Cost Savings

- Energy Reduction: The client experienced a 40% decrease in energy consumption compared to previous curing methods.

- Lower Maintenance Costs: The long lifespan of LED lamps and reduced need for replacement parts contributed to significant savings.

Environmental Impact

- Sustainability: The elimination of harmful emissions and reduced energy consumption aligned with the client’s environmental goals.

Conclusion

The installation of IUV’s LED UV curing system on the new Omet Kflex press has transformed our client’s printing operations. This integration has delivered measurable improvements in print quality, production efficiency, and environmental sustainability. As the printing industry continues to evolve, adopting such advanced technologies will be crucial for businesses aiming to maintain a competitive edge and meet growing market demands.