Printing Industry

and less downtime.

range of print substrates.

and better adhesion.

migration processes.

monitoring and diagnostics.

or ozone, reduce environmental hazards.

maintain a healthy working environment.

waste and recyclable materials available.

Why Is IUV

Lighting up LED UV is easy,

ensuring their long-term

stable high-performance

take expertise.

Cost Saving

70% Energy Saving, 80%Maintance Saving, No Consumable Spares.

Automatic Control

Automatically Identify And Adjust Base On Real-time Runing Data.

System Stability

Unique Technology To Ensure UV System Long-term Stable High Performance.

Rich Experience

IUV LED UV System Was Proved In Almost All Brands And Models Of Flexo And Offset Printing Line.

IUV LED Elevate Your Printing Process

Fast Printing

LED UV is instant-On curing at much faster rate. Easily Up to 200m/min print.

Better Color

Sharper images, vibrant colors, improved overall print quality.

Less Defects

Consistent and stable light output, fewer print defects and less waste.

Material Compatibility

Take on a broader variety of jobs without worrying about substrate compatibility issues.

Print Product Durability

Penetrates deeper into the ink, creating a stronger bond and better durability.

Reduced Ink Migration

Reduce the occurrence of ink migration, leads to cleaner, more professional-looking prints.

Overprint Registration

LED UV systems allow for better overprint registration, bring accurate, sharp registration and fewer defects.

Customizable Solutions

IUV LED UV systems can be tailored to meet the specific needs.

Intelligence And Stability

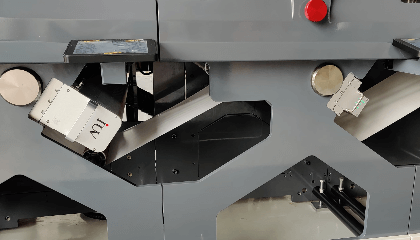

Innovation UV Technology

IUV developed up series of unique technology to maximize printing cost savings and system life, like automatic material sensing technology, mercury-LED hybrid technology and power protection technology.

Intellignt Automatic Control

IUV's patented UV technology allows the system to automatically identify and adjust base on the real-time runing data.

Innovation UV Technology

IUV developed up series of unique technology to maximize printing cost savings and system life, like automatic material sensing technology, mercury-LED hybrid technology and power protection technology.

Remote Monitoring And Diagnosis

Provides real-time remote monitoring and diagnostic functions, which can warn of abnormalities in advance and promote proactive maintenance.

Frequently Asked Questions

What you need to pay attention to when upgrade to LED UV Curing?

1 What is the difference between a mercury UV and LED UV system?

Light Source:

– Mercury Lamp Curing System: Uses a mercury vapor lamp as the ultraviolet light source. Mercury lamps are traditional UV curing light sources that generate UV radiation by exciting mercury vapor.

– LED Ultraviolet Curing System: Utilizes LEDs (Light Emitting Diodes) as the ultraviolet light source. LED curing technology is relatively newer and produces UV light directly through LED chips.

Spectral Characteristics:

– Mercury Lamp Curing System: Mercury lamps typically produce a broad spectrum of UV light, including a significant amount of visible light and short-wave ultraviolet, which may generate unnecessary heat.

– LED Ultraviolet Curing System: LED systems can precisely control the spectrum, providing a narrower UV bandwidth closer to the desired curing wavelength, reducing unnecessary heat and energy waste.

Power and Efficiency:

– Mercury Lamp Curing System: Mercury lamps usually have higher power requirements, but their efficiency is relatively lower, resulting in more heat and energy waste.

– LED Ultraviolet Curing System: LEDs have lower power demands and higher efficiency since they directly produce the required UV light wavelength, reducing energy loss.

Lifespan:

– Mercury Lamp Curing System: Mercury lamps have a relatively short lifespan and need regular replacements, increasing maintenance costs.

– LED Ultraviolet Curing System: LEDs have a longer lifespan and typically outlast mercury lamp curing systems, reducing maintenance frequency and costs.

Environmental Friendliness:

– Mercury Lamp Curing System: Mercury is a toxic substance, and the mercury vapor in mercury lamps can pose potential hazards to the environment and health. Therefore, the use and disposal of mercury lamps require careful handling.

– LED Ultraviolet Curing System: LED systems are mercury-free, making them more environmentally friendly.

2 Why should I upgrade to LED UV Curing?

Upgrading to LED UV curing offers significant advantages, including energy efficiency, cost savings, environmental sustainability, faster curing times, and improved material compatibility. LEDs provide uniform curing, reduced maintenance, enhanced safety, and adaptability to various production needs.

IUV's unique digital UV control technology offers fully intelligent automatic control. Maximize electricity cost savings and the lifespan of LED modules, reduce material temperature, minimize manual operations.

This upgrade not only boosts productivity and quality but also future-proofs your operations against evolving market demands.

升级到LED UV固化系统可降低能耗高达70%,同时提升生产效率30%

3 Can IUV LED UV system work with my old printing equipment?

IUV's advanced LED UV curing systems have been successfully integrated with nearly all brands and models of printing equipment on the market, delivering long-term, stable, and high-performance results. Whether you're using older machinery or the latest models, our systems are designed to enhance your productivity and efficiency.

- As the official supplier to numerous well-known OEMs in the printing industry, IUV brings unparalleled customization capabilities and extensive project experience. Our team works closely with you to tailor solutions that meet your specific needs, ensuring seamless integration and optimal performance.

- Upgrade your printing operations with IUV's cutting-edge LED UV technology and experience the difference of working with a trusted industry leader.

4 About the change from UV Ink to LED UV Ink

Making the switch to LED UV ink is easier than ever, thanks to the mature and reliable formulations from globally recognized ink brands like Flint, Siegwerk, and Zeller. These industry leaders have developed advanced LED UV inks that deliver exceptional performance, vibrant colors, and unmatched durability.

At IUV, we integrate seamlessly with these top-tier ink solutions, ensuring your transition to LED UV technology is smooth and hassle-free. Our LED UV curing systems are designed to maximize the benefits of these inks, offering faster curing times, reduced energy consumption, and superior print quality.

5 Why IUV prefer water cooled LED UV curing systems rather than air cooled?

After 15 years of UV development and production, IUV's R&D team has made a professional analysis and experience summary of air and water cooling for LED UV curing systems.

- Air-cooled cooling is only suitable for low-power, low-density LED UV Lamp, while high-power LED UV Lamp has high heat capacity, air-cooling can not achieve the best cooling effect.

- Air-cooled LED UV curing system's UV energy is low, the power is low and the curing and drying effect is not good.

- Poor cooling effect of the air-cooled LED UV curing system will lead to shortened chip life of the LED Lamp and accelerated UV energy.

- Air-cooled has dust and noise, which has a negative impact on the environment.

6 How IUV will process the LED UV upgrade project?

Step1 Client Requirements Analysis Step2 Printing Equipment Evaluate

Step3 Feasibility Assessment Step4 Customization Options

Step5 Cost-return Analysis Step6 Project Install

Step7 System Technical Support and Training

7 What makes IUV's after-sales support stand out?

At IUV, we are committed to providing unparalleled after-sales support to ensure your operations run smoothly and efficiently. Here's how we stand by our customers:

24/7 Online Support: Our dedicated technical team is available around the clock to assist you with any queries or issues, ensuring minimal downtime and maximum productivity.

Global Localized Support: With strategically located spare parts inventories and technical personnel across multiple countries, we deliver fast and reliable service wherever you are.

On-Site Installation & Training: IUV offers free on-site technician dispatch for system installation and provides professional maintenance training to empower your team with the knowledge to operate and maintain your equipment confidently.

Experience the IUV difference – where innovation meets exceptional support

8 Is the IUV System a Worthwhile Investment for You?

When evaluating the IUV system as a potential investment, it's important to consider key factors from a buyer's perspective:

1. Cost Efficiency and ROI

The IUV system offers significant cost-saving opportunities by automating processes, reducing manual errors, and optimizing resource allocation. For any buyer, understanding the return on investment (ROI) is essential. The IUV system provides measurable gains in operational efficiency, helping you cut unnecessary costs while boosting overall productivity.

2. Scalability

As your business grows, the IUV system can scale alongside your needs, allowing for seamless adaptation to increasing demands and expanding operations. This flexibility ensures that your investment remains relevant and valuable long-term, without the need for constant upgrades or replacements.

3. Data-Driven Insights

The IUV system empowers you with actionable insights by analyzing vast amounts of data to identify trends, opportunities, and areas of improvement. For buyers looking to make informed, data-backed decisions, this feature provides a powerful advantage in the marketplace.

4. Competitive Advantage

By implementing cutting-edge AI technology, the IUV system gives you a distinct edge over competitors. Buyers can expect improved market positioning through smarter decision-making, helping your business stay ahead of industry trends and consumer demands.

5. Long-Term Value

The IUV system is designed for long-term value, offering continuous updates and improvements to ensure that your investment remains current and effective over time. It's not just a short-term solution but an asset that will continue to contribute to your business's success for years to come.

Looking For Premium

UV Curing Solution?

Contact With IUV Experts Now!

We can provide valuable insights

and help you with the most suitable LED UV curing solution for you!

Contact IUV Experts

ROI Calculator

Check How Much You Can Save With IUV LED UV Curing System

Stop guessing, start calculating!

Discover the true potential of your investment with IUV’s advanced LED UV curing technology. Our systems are designed to deliver efficiency, durability, and cost savings, helping you achieve a faster return on investment (ROI).

See the numbers for yourself!

Click the ROI Calculator below to estimate how much you can save by switching to IUV LED UV curing systems.

Take the first step toward smarter investments and greater savings for your business!

Explore More

4 lampes UV LED (1,6 kW) : IUV assure d’excellentes économies sur Nilpeter FB

Nilpeter

Revolutionizing Flexo Printing withInterchangeable UV curing

OMET

The project’s success with IUV ability to enhance print quality, increase productivity, and sustainability.

Bobst

With IUV’s LED UV curing system, enhanced production capabilities, and sustainability.

Gallus

IUV’s LED UV retrofit for fast curing , energy savings, and extended equipment lifespan.

Mark Andy

The UV LED upgrade for the MPS EF-430 is a testament to efficiency and sustainability.

MPS