The Science Behind UV Curing Systems in Flexographic Printing

Flexographic printing thrives on speed, precision, and adaptability—qualities amplified by advanced UV curing systems. As label, narrow-web, and packaging markets demand faster turnaround and higher-quality outputs, understanding the interplay between UV technology and flexo processes becomes critical. This article explores the chemistry, engineering, and practical advantages of UV curing in modern flexographic applications.

How UV Curing Works: A Chemical Perspective

UV curing relies on photopolymerization, a process where ultraviolet light triggers a rapid chemical reaction in specially formulated inks, coatings, or adhesives. These formulations contain photoinitiators—molecules that absorb UV energy and generate free radicals or reactive ions. These active particles then bond monomers and oligomers into hardened polymer chains, transforming liquid ink into a durable, dry film in milliseconds.

Unlike conventional solvent-based drying, UV curing eliminates volatile organic compounds (VOCs) and reduces energy consumption by skipping evaporation stages. For flexo printers, this translates to sharper dot reproduction, reduced substrate warping, and compatibility with heat-sensitive materials like thin films or pressure-sensitive labels.

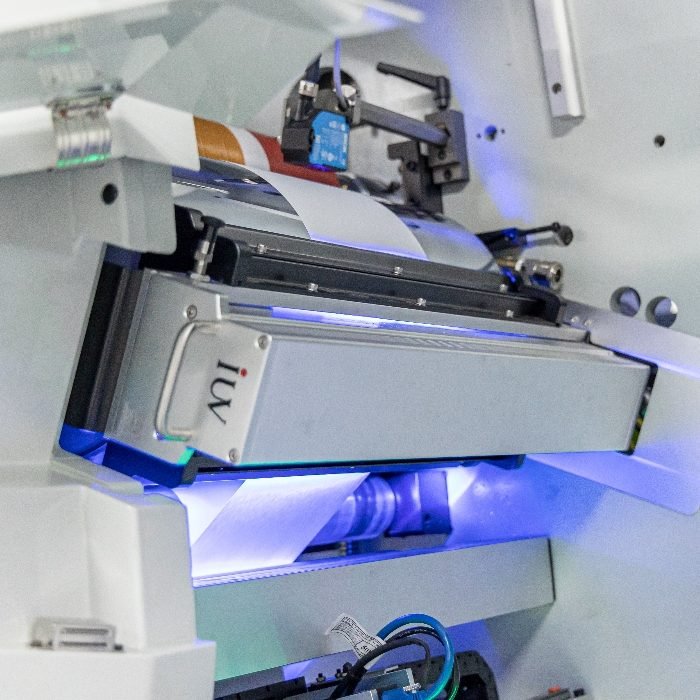

LED UV vs. Mercury Arc Lamps: Efficiency Redefined

Traditional mercury-vapor lamps dominated UV curing for decades but faced criticism for high heat output, limited lifespan, and mercury disposal challenges. LED UV systems now lead the shift toward sustainable curing. By emitting precise wavelengths (typically 365–405 nm), LEDs target photoinitiators more efficiently, slashing energy use by up to 70% and operating at near-ambient temperatures.

For narrow-web and label printers, LED UV’s instant on/off capability minimizes downtime during job changes. Its cooler operation also prevents distortion in thin films or shrink sleeves—a game-changer for high-detail beverage labels or pharmaceutical packaging.

Applications Across Printing Methods

1. Label Printing: UV-curable inks excel in producing scratch-resistant, glossy labels for cosmetics or chemicals. Their rapid curing allows inline finishing (e.g., die-cutting, lamination) without intermediate drying stages.

2. Flexible Packaging: UV systems enable high-opacity white inks and metallic effects on polyethylene or BOPP films, critical for snack bags or stand-up pouches.

3. Corrugated Printing: Hybrid UV/water-based systems balance durability and cost for shipping boxes, curing only the top layer to maintain substrate flexibility.

4. Offset Integration: While flexo dominates labels, UV curing also enhances sheetfed offset for premium cartons, combining offset’s color fidelity with UV’s instant drying.

Key Advantages in Flexographic Workflows

- Faster Speeds: UV curing eliminates drying delays, supporting press speeds exceeding 600 feet/minute.

- Enhanced Color Stability: Inks cure immediately, preventing dot gain and ensuring consistent Pantone matches.

- Eco-Friendly Operations: VOC-free formulations align with global sustainability mandates like EuPIA and REACH.

- Reduced Waste: Instant curing minimizes substrate contamination from uncured ink transfer.

Overcoming Challenges: Optimizing UV Performance

To maximize UV curing efficiency, printers must address:

- Ink Formulation: Photoinitiator concentration must match the LED’s wavelength output. Too little initiator risks under-curing; excess causes brittleness.

- Substrate Compatibility: Non-porous materials like synthetic labels require tailored adhesion promoters.

- Oxygen Inhibition: Atmospheric oxygen can hinder surface curing. Nitrogen inerting or dual-cure (UV/EB) systems mitigate this in high-end applications.

The Future of UV in Flexo Printing

Innovations like low-migration UV inks (for food-safe packaging) and hybrid LED/IR systems (for opaque white layers) continue to expand UV’s versatility. As regulatory pressures mount against solvent-based inks, UV and EB curing technologies will dominate the next era of flexographic, offset, and narrow-web printing.

For printers seeking to upgrade their capabilities, investing in UV curing systems isn’t just about keeping pace—it’s about redefining what’s possible in color accuracy, substrate range, and environmental stewardship. By aligning chemistry, engineering, and process design, UV technology transforms flexographic printing from a conventional method into a high-performance, future-ready solution.